We finished up the dry wall on friday. By we I of course mean the drywall guy. I helped him with the one board on the ceiling and thats about it. Here are pictures of the results. A base mud coat was done followed by a top coat of limestone. $400 for labor & materials. We are all pretty happy that we did not have to do this part ourselves.

Unfortunately, its going to take 1-2 weeks to dry all of the way. We just spent sunday cleaning everything up. The garage is now completely empty and cleaned up all of the plaster from the floors etc while it was still easy to remove. Here is the plan for this week.

- Clean and seal the cement floor inside and out on the patio.

- Paint on a epoxy floor outside and put in an epoxy or wood floor inside

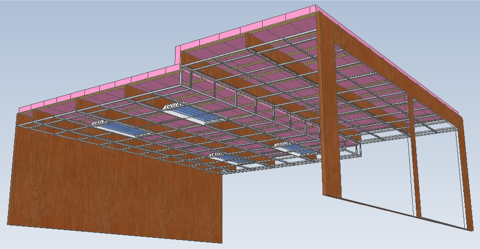

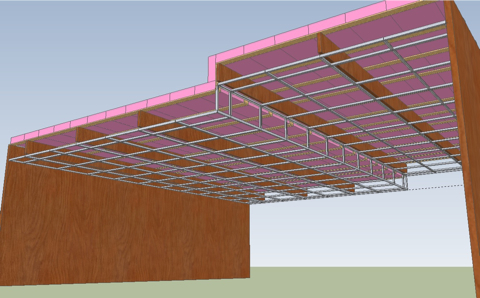

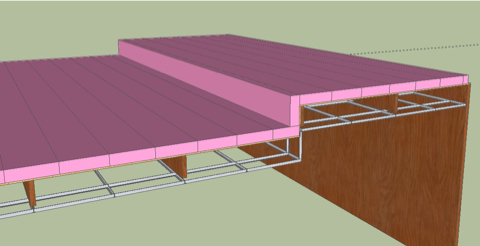

- Buy materials for the drop ceiling + insulation

- Buy paint to paint walls with

- Screen in the outdoor patio

Then this weekend we hope the plaster is dry enough to put up the edges we need for the drop ceiling into the walls. After that only a few minor things like window trim and baseboards remain.

One big decision we have left to make is wether to go with an epoxy floor inside or to make a slightly raised floor from wood.

Wood floor would be nicer to stand on and look nicer. Also it could be insulated underneath. On the other hand it will most likely cost alot more than epoxy, not be as tough on beer spills, and the biggest issue, the ceiling height is currently ~7ft. Reducing it by ~4" to put in insulation/supports for a floor then the wood floor itself would really make the inside start to feel small.

Any thoughts?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)