Thanks! Working on a clogged plate chiller, and debating on putting it in the oven on a cleaning cycle.... Here are some pics of the first brew day. I had my buddy Thomas come out on Saturday to mill and help out. Sunday I brewed.

My family was a little busy with other things.

So I called on Thomas my friend of 30 years to help out.

Pumping lye through the chiller

Thomas milling

Boulder CO uses chlorine, so I boil the day prior and let it stand over night.

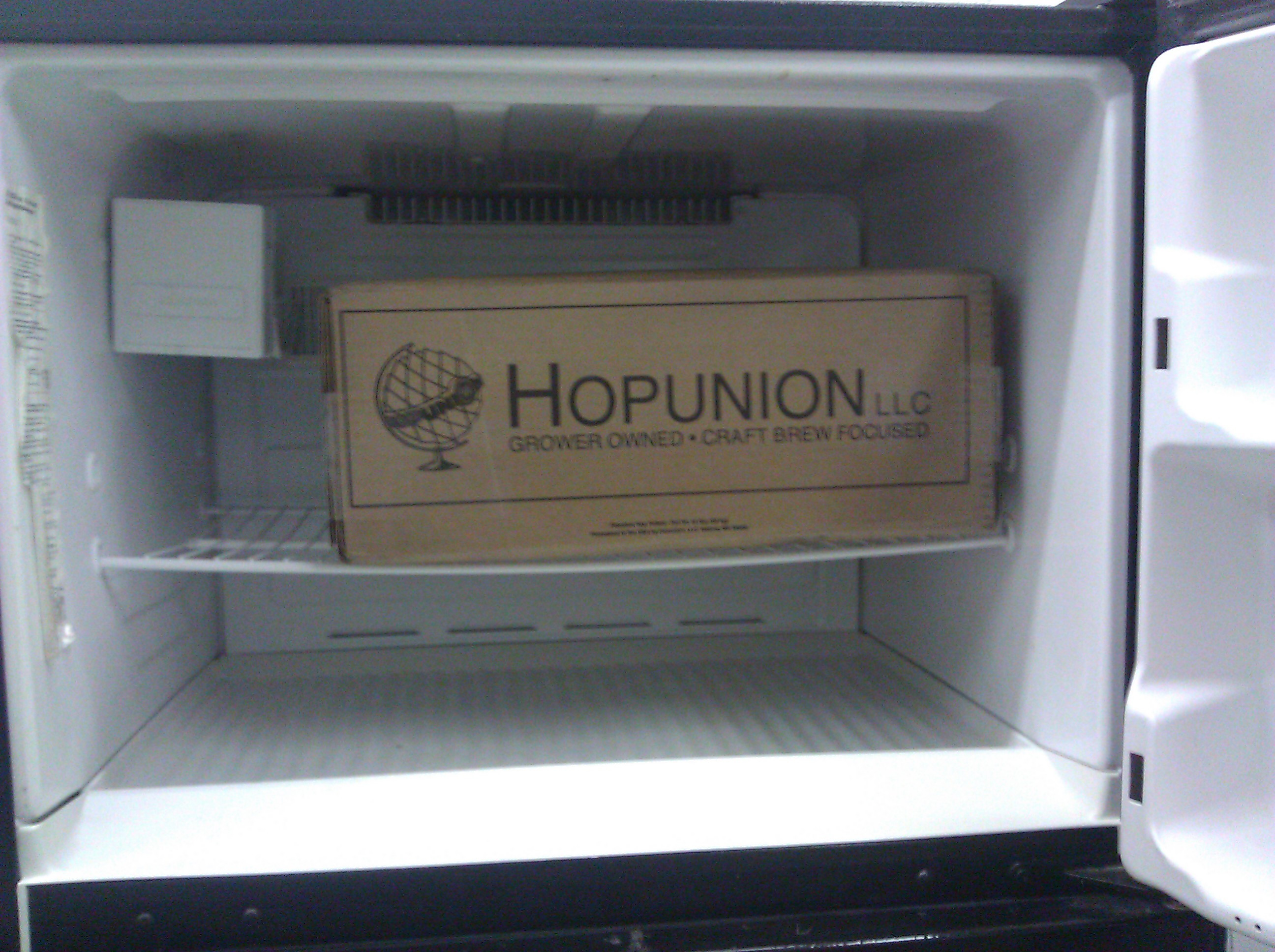

Simcoe!

Sanitizing a fermenter for the yeast starter. Made two, one for Hop Haze, one for Chocolate Milk Stout

Mashing. Using the funnel to distribute the water so I wont get too much channeling.

I lauterd into a bucket, then dumped it back. Here's the mash runoff, started the kettle about half way full.

Came to boil in about an hour. Talking with the landlord about increasing the gas pressure to 11" wc. Were at 7 now.

Hops I got out of the kettle, what was left. My ss scrubbie got clogged, so, I just removed it and ran everything through the plate chiller. That was a terrible idea btw. Looking back I should have ran home and used my keggle as a grant, or got my hop spider and pumped everything into that, then run it through the chiller. Hop spider pumping idea I got from bmbigda's post after the fact.

Only two boilover events. First one was when I thought, "eh, were good" and started shoveling out the MT. Unwatched pot always boils over? Second time, I dumped in the 60 min hops, bam! malt explosion!

The starter worked great, was fermenting the next morning just fine. Going to make some more starters tonight.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)