Falstaff

A Bad Influence

- Joined

- Jul 14, 2021

- Messages

- 411

- Reaction score

- 884

Extremely frustrated with my brews lately and wondering if anyone can help me figure it out.

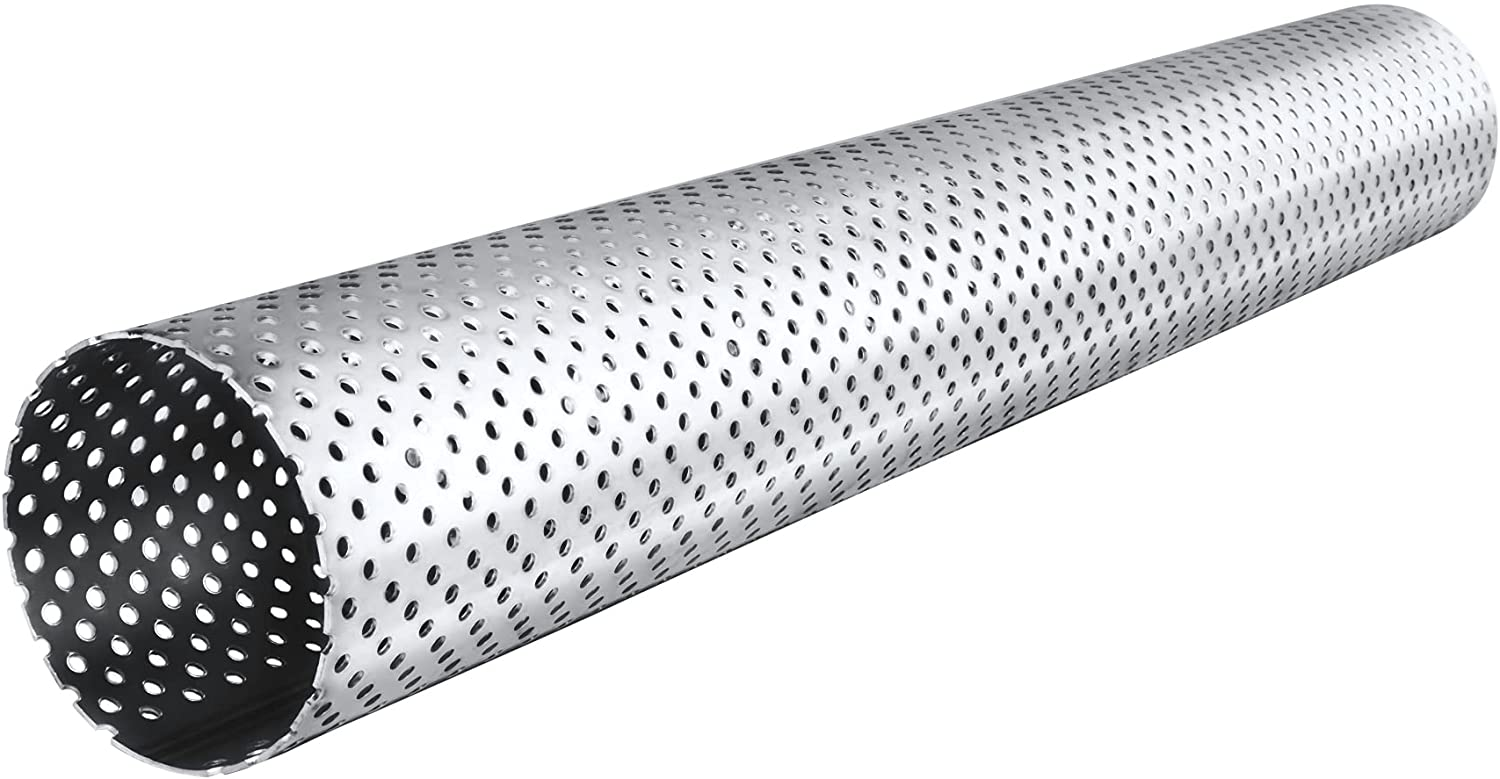

I have a 5ga cooler with a round false bottom. It connects to the valve with a silicone tube. I wish i could take pictures but my phone is broken and I wont have a new one until tomorrow.

I thought I was overloading the cooler with 10lbs of grain so I brewed a 5ga session batch today and NOTHING came out again. I blow through the tube and nothing happens. I try to slice the grain bed but there isnt one to slice. Nothing is compacted. I empty into the kettle, clean everything, pour it back in. Nothing. Finaly I switched to a collander that I used to use when I first started brewing, and finaly it came out, but the collander doesnt create a good grain bed so now I will probably have a hazy brown, which just looks like mud. I ran it through a hop spider to catch some of the sludge and hulls.

Because it worked after the switch, I'd imagine the valve isn't the culprit.

Could the tube be getting crushed? I opened the valve as soon as I put the water in this time to get water into it, so there would be equal pressure. Also, I've used that silicone many times with no problems

Could it be the crush at my LHBS? I've recently switched to them crushing my grain instead of me, because im lazy. I can't imagine this is the problem either because there was ZERO liquid comming out. Not even a trickle. I'd imagine I'd be able to feel the compaction with my brew spoon.

I've had stuck mashes before but never this many in a row, and never where NOTHING came out of the valve no matter what I did.

Thanks for any help.

I have a 5ga cooler with a round false bottom. It connects to the valve with a silicone tube. I wish i could take pictures but my phone is broken and I wont have a new one until tomorrow.

I thought I was overloading the cooler with 10lbs of grain so I brewed a 5ga session batch today and NOTHING came out again. I blow through the tube and nothing happens. I try to slice the grain bed but there isnt one to slice. Nothing is compacted. I empty into the kettle, clean everything, pour it back in. Nothing. Finaly I switched to a collander that I used to use when I first started brewing, and finaly it came out, but the collander doesnt create a good grain bed so now I will probably have a hazy brown, which just looks like mud. I ran it through a hop spider to catch some of the sludge and hulls.

Because it worked after the switch, I'd imagine the valve isn't the culprit.

Could the tube be getting crushed? I opened the valve as soon as I put the water in this time to get water into it, so there would be equal pressure. Also, I've used that silicone many times with no problems

Could it be the crush at my LHBS? I've recently switched to them crushing my grain instead of me, because im lazy. I can't imagine this is the problem either because there was ZERO liquid comming out. Not even a trickle. I'd imagine I'd be able to feel the compaction with my brew spoon.

I've had stuck mashes before but never this many in a row, and never where NOTHING came out of the valve no matter what I did.

Thanks for any help.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)