Adrian Gresores

Active Member

- Joined

- Nov 16, 2019

- Messages

- 35

- Reaction score

- 4

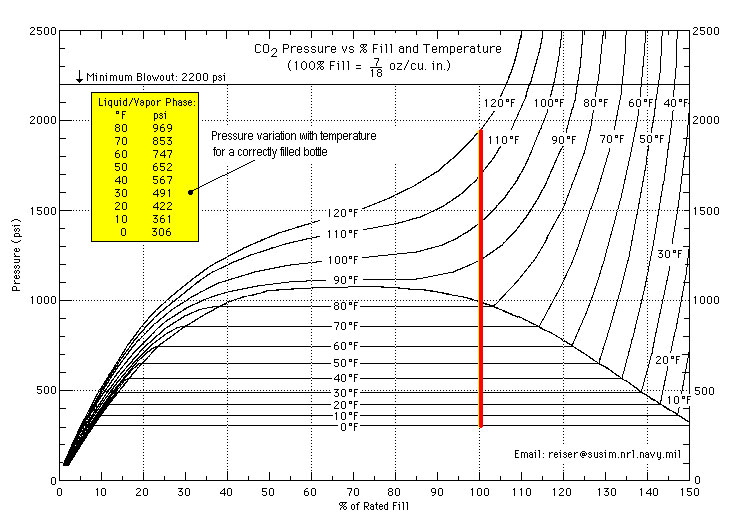

I have re-done my keezer gas manifold recently and have twice emptied out my 20lb CO2 tank over a period of days. I have tried, but cannot find the leak so far. I am going to re-assess the setup and try to tighten it up. However, I would like to have a better way of assessing slow, but continuing, gas losses from the tank. Following pressure is inadequate as it will not drop until the supply of liquid CO2 in the tank becomes critically low. The best method would be to follow the weight of the tank.

Does anyone have any suggestions as to an economical scale that I could keep the tank on and follow weight that way? Or any other ideas?

Thanks.

Does anyone have any suggestions as to an economical scale that I could keep the tank on and follow weight that way? Or any other ideas?

Thanks.