Hi everyone,

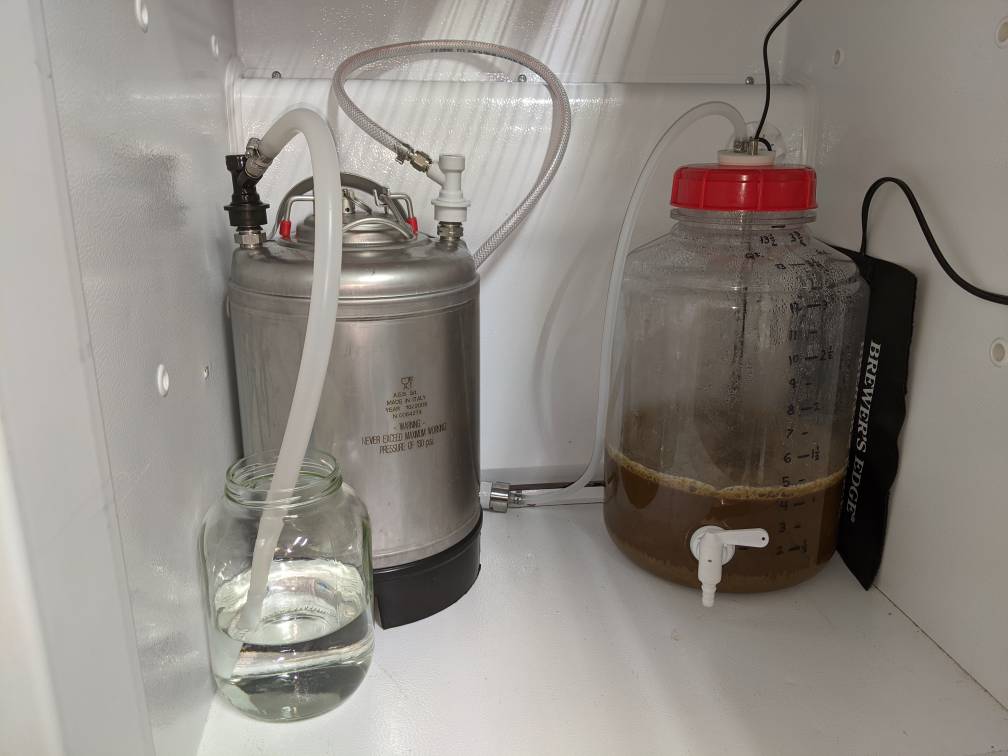

I'm trying out something new for the first time, and having some unexpected results. I've read about people flushing their kegs with CO2 produced during fermentation by hooking the blowoff into the keg gas in, and then connecting the liquid out to a tube in a jar of StarSan. Basically, it's just an extended blowoff tube with the keg in between, which gets continuously flushed with CO2. Since I'm also planning on spunding it at the end of fermentation, this should also make the transfer super easy as almost everything is already hooked up and the keg and transfer tube are already sanitized.

That said, something seems to be going wrong. After 2 days of fermentation, my SG is dropping as expected, but I'm getting zero bubbles in the sanitizer jar. The gas must be escaping somewhere, as it hasn't blown up, but it doesn't seem to be coming out of the keg. I've checked all the connections and they seem to be fine. For anyone else who's done this before, is there something I'm missing? Have you had similar experiences? Could the increased back-pressure of the keg-blowoff-tube-jar system be too much, and it's forcing the CO2 to vent elsewhere (around the seals, perhaps)?

Thanks!

I'm trying out something new for the first time, and having some unexpected results. I've read about people flushing their kegs with CO2 produced during fermentation by hooking the blowoff into the keg gas in, and then connecting the liquid out to a tube in a jar of StarSan. Basically, it's just an extended blowoff tube with the keg in between, which gets continuously flushed with CO2. Since I'm also planning on spunding it at the end of fermentation, this should also make the transfer super easy as almost everything is already hooked up and the keg and transfer tube are already sanitized.

That said, something seems to be going wrong. After 2 days of fermentation, my SG is dropping as expected, but I'm getting zero bubbles in the sanitizer jar. The gas must be escaping somewhere, as it hasn't blown up, but it doesn't seem to be coming out of the keg. I've checked all the connections and they seem to be fine. For anyone else who's done this before, is there something I'm missing? Have you had similar experiences? Could the increased back-pressure of the keg-blowoff-tube-jar system be too much, and it's forcing the CO2 to vent elsewhere (around the seals, perhaps)?

Thanks!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)