Owly055

Well-Known Member

- Joined

- Feb 28, 2014

- Messages

- 3,008

- Reaction score

- 687

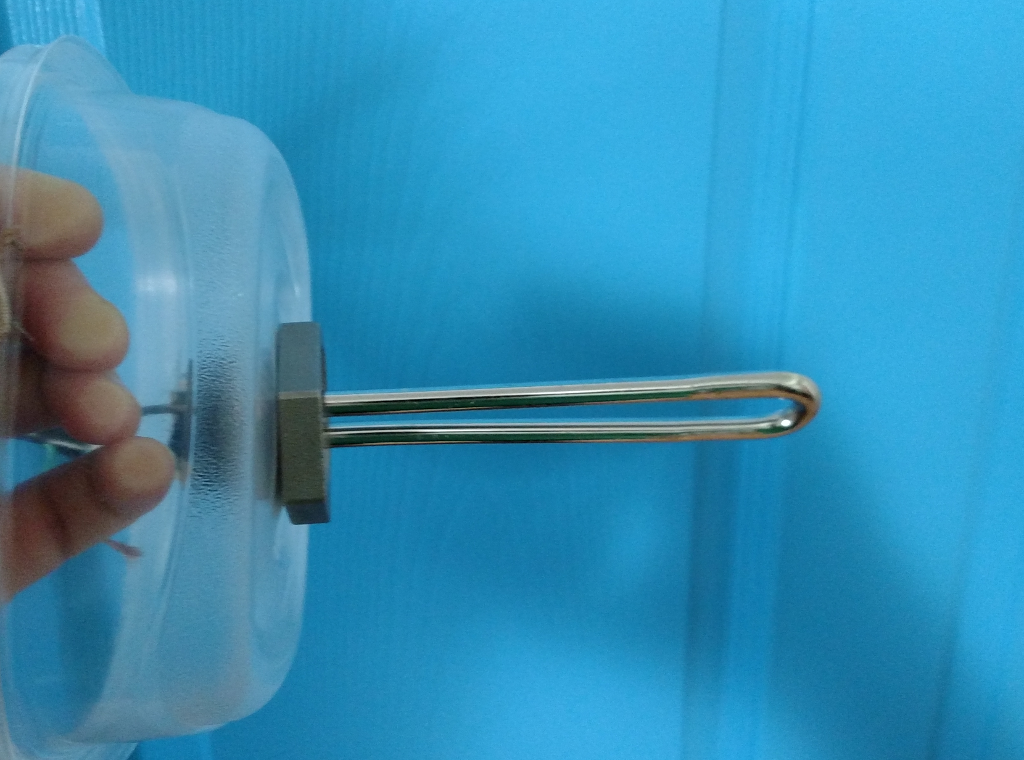

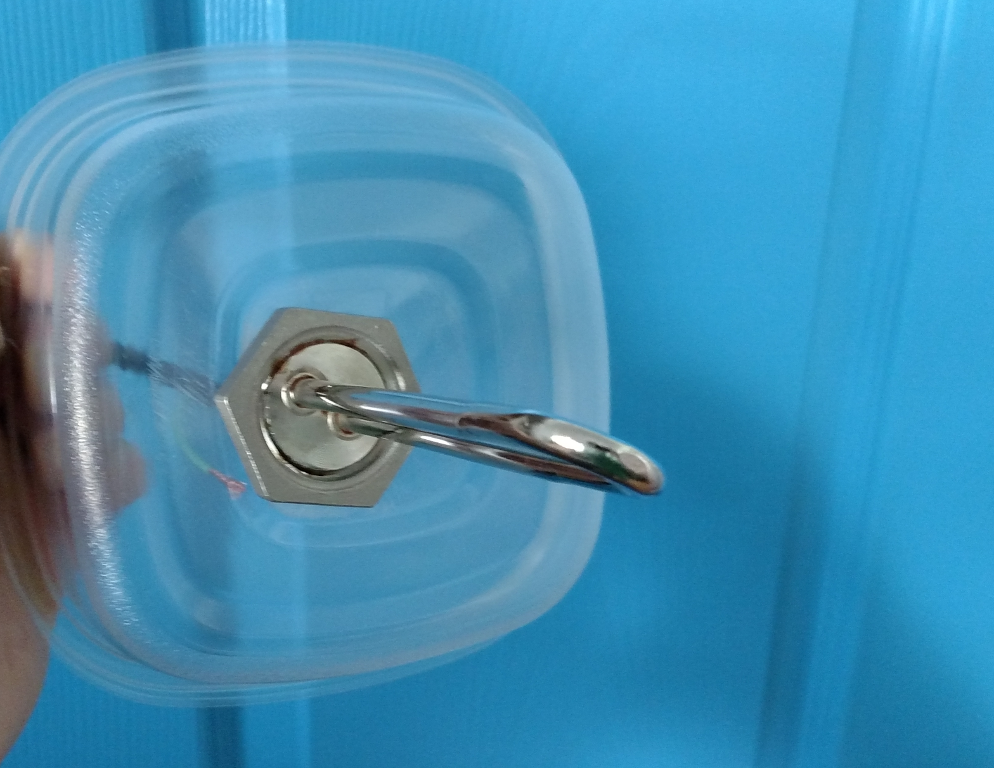

I recently built a floating heating element........... for a non brewing application. It was extremely simple and worked very well..........nor am I worried about shock due to having sealed the connections well. A ground fault protector would be an added layer of protection. In this case the element was made from a car tank heater.... as it was not heating anything for human consumption......... and my float was made from ordinary blue foam... again, I wasn't going to drink the liquid I was heating.

It occurs to me that the same principle could be applied to a brew kettle using a water heater element for the boil. Simply take a small stainless steel pot, mount your water heater element through a hole in the bottom, hook up your wires, and pour some polyester resin or some other resin in the bottom to seal the connections, and float it in the wort, strike water, etc.... An ultra low current density element would eliminate scorching / burning of wort. It could be easily transferred into whatever pot you were using.......... even the mash tun, provided you stirred steadily as you were heating.

H.W.

It occurs to me that the same principle could be applied to a brew kettle using a water heater element for the boil. Simply take a small stainless steel pot, mount your water heater element through a hole in the bottom, hook up your wires, and pour some polyester resin or some other resin in the bottom to seal the connections, and float it in the wort, strike water, etc.... An ultra low current density element would eliminate scorching / burning of wort. It could be easily transferred into whatever pot you were using.......... even the mash tun, provided you stirred steadily as you were heating.

H.W.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)