- Joined

- Nov 19, 2017

- Messages

- 250

- Reaction score

- 93

About a month ago I picked up a 7 gallon Anvil Fermentor. I really love this thing -- except for the lid. Why they didn't just go ahead and put a 1.5" TC ferrule on it?! The good news is that installing one seems pretty straight forward. I've soldered plenty of bulkheads before, so I'm not afraid.

It appears the opening in the lid is 1-1/8", so just stick a step bit in there, and expand it to 1-1/4"

https://www.brewhardware.com/product_p/tc15lwf.htm

$4.60 1.5" TC Ferrule

https://www.brewhardware.com/product_p/ptbulkhead_tool15tc.htm

$29.99 pull through tool to dimple the lid (I already have the flux and solder from building my HLT)

For primary fermentation, I could use a simple 90 degree 1/2" barb blow off fitting:

https://www.ssbrewtech.com/collecti...-5-tri-clover-to-1-2-hose-barb-with-90-d-bend

$14.95

Cleaning would be a snap with a micro spray ball:

https://www.ssbrewtech.com/collections/accessories/products/mini-cip-spray-ball-1-5-tc-assembly

$42.50

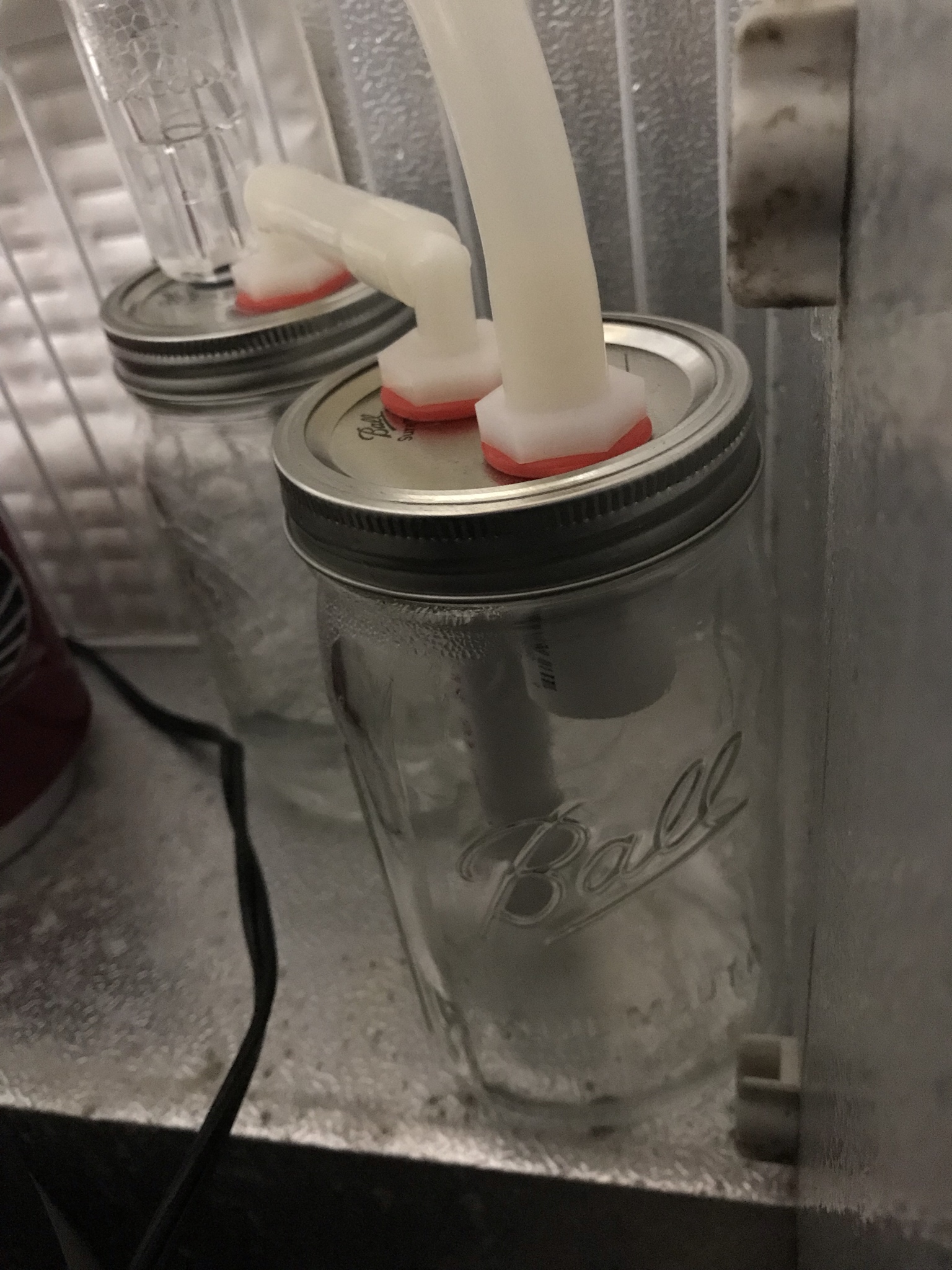

...but the one thing that's holding me up is that I usually switch to a 3 piece air lock when cold crashing, because I don't want to suction a pitcher of StarSan into the fermentor when I drop the temp (I learned this lesson the hard way about a year ago). This is where I'm stuck -- does anyone have any recommendations on what to do before cold crashing? Is there another TC fitting I could use with an air lock, or maybe a better solution?

It appears the opening in the lid is 1-1/8", so just stick a step bit in there, and expand it to 1-1/4"

https://www.brewhardware.com/product_p/tc15lwf.htm

$4.60 1.5" TC Ferrule

https://www.brewhardware.com/product_p/ptbulkhead_tool15tc.htm

$29.99 pull through tool to dimple the lid (I already have the flux and solder from building my HLT)

For primary fermentation, I could use a simple 90 degree 1/2" barb blow off fitting:

https://www.ssbrewtech.com/collecti...-5-tri-clover-to-1-2-hose-barb-with-90-d-bend

$14.95

Cleaning would be a snap with a micro spray ball:

https://www.ssbrewtech.com/collections/accessories/products/mini-cip-spray-ball-1-5-tc-assembly

$42.50

...but the one thing that's holding me up is that I usually switch to a 3 piece air lock when cold crashing, because I don't want to suction a pitcher of StarSan into the fermentor when I drop the temp (I learned this lesson the hard way about a year ago). This is where I'm stuck -- does anyone have any recommendations on what to do before cold crashing? Is there another TC fitting I could use with an air lock, or maybe a better solution?