blacktooth1313

Well-Known Member

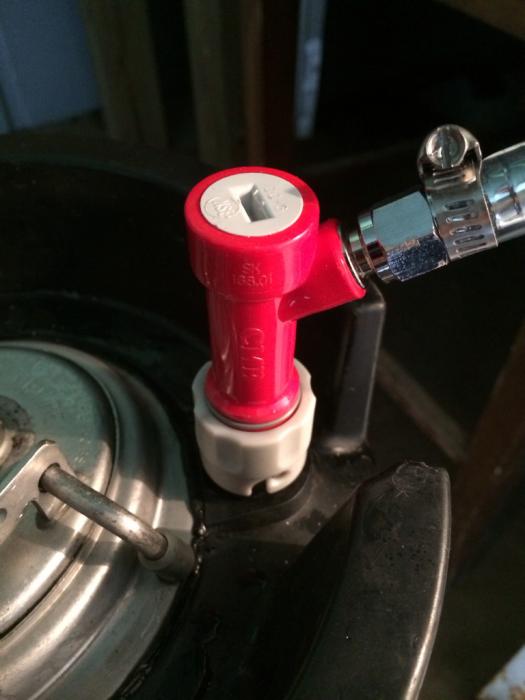

Just finished first home brew and wanting to keg I have everything I need just I've watched 100 you tube videos and read articles and they are all different . Any help on a basic way that all agree upon would help thanks

Sent from my iPhone using Home Brew

Sent from my iPhone using Home Brew

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)