I'm doing a lager for the first time with an Oktoberfest and was curious about when to do the diacetyl rest. I'm using White Labs Oktoberfest yeast. I pitched a little warm at 60F but lowered to 52F. Also, when do I rack to secondary?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

First time lager help

- Thread starter Lushife

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

You'll raise, or begin your free-rise to d-rest temp when you have a few gravity points left to go, so a hydrometer (ideally) is needed to see where things stand. If you are headed down to 1.008 for instance, start the rest in the 1.016-1.020 range, it will hit FG once the rest is complete.

Once your d-rest is complete, go directly to packaging, whether kegs or bottles, and skip secondary entirely.

It's not necessary, nor recommended anymore for beers you aren't going to age (aside from cold conditioning/lagering, which is what happens in the serving keg or bottles anyway).

Once your d-rest is complete, go directly to packaging, whether kegs or bottles, and skip secondary entirely.

It's not necessary, nor recommended anymore for beers you aren't going to age (aside from cold conditioning/lagering, which is what happens in the serving keg or bottles anyway).

I use clear fermenters ,and when the krausen starts to fall,around day 5-7 (with a 1.050 at 50*) I'll start a 3 day temp increase,55*-60* and then to 64 for the sulphery ones. I leave them in primary for 3 weeks or so then keg ,condition for 1 week at ambient then into a 33* lagerator with CO2.

Steveruch

Well-Known Member

First off you need to determine if a d-rest is even needed.

- Joined

- May 28, 2018

- Messages

- 3,265

- Reaction score

- 2,979

I generally ramp up and D rest anything that fermented below 55F or so. It assures the yeast will clean beer up to fullest degree, and I don't see any downside, even if little diactyl is detected.

This is the first time with this recipe so I'm sure what the finishing gravity should be. This is the recipe Brewfather

I copied it from a YouTuber with a couple changes. I don't have it in front of me but I think the OG was 1.057.

I copied it from a YouTuber with a couple changes. I don't have it in front of me but I think the OG was 1.057.

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

Would I determine the need for a diacetyl rest by tasting/smelling? Would it hurt to do it if it doesn't need it? Right now it smells pretty sulphury. I brewed on Sunday but it was like 2 AM by the time I pitched.

Would I determine the need for a diacetyl rest by tasting/smelling? Would it hurt to do it if it doesn't need it? Right now it smells pretty sulphury. I brewed on Sunday but it was like 2 AM by the time I pitched.

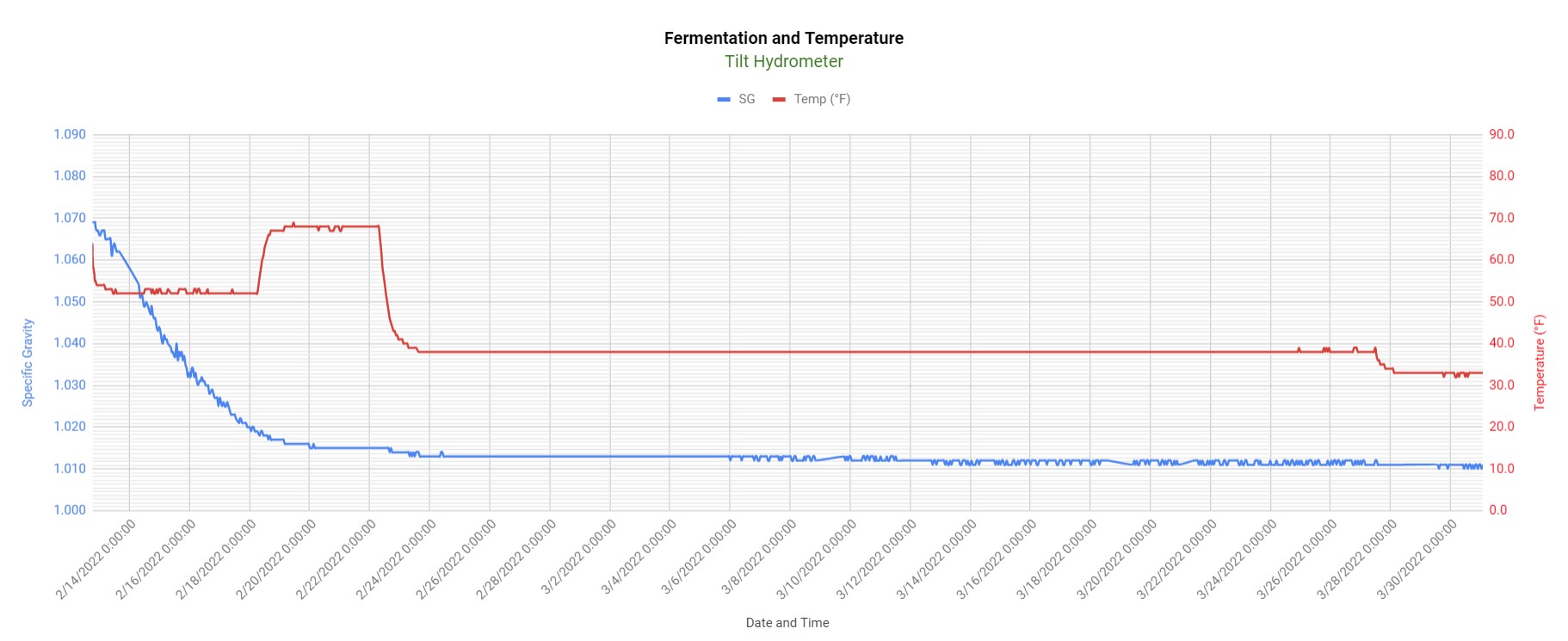

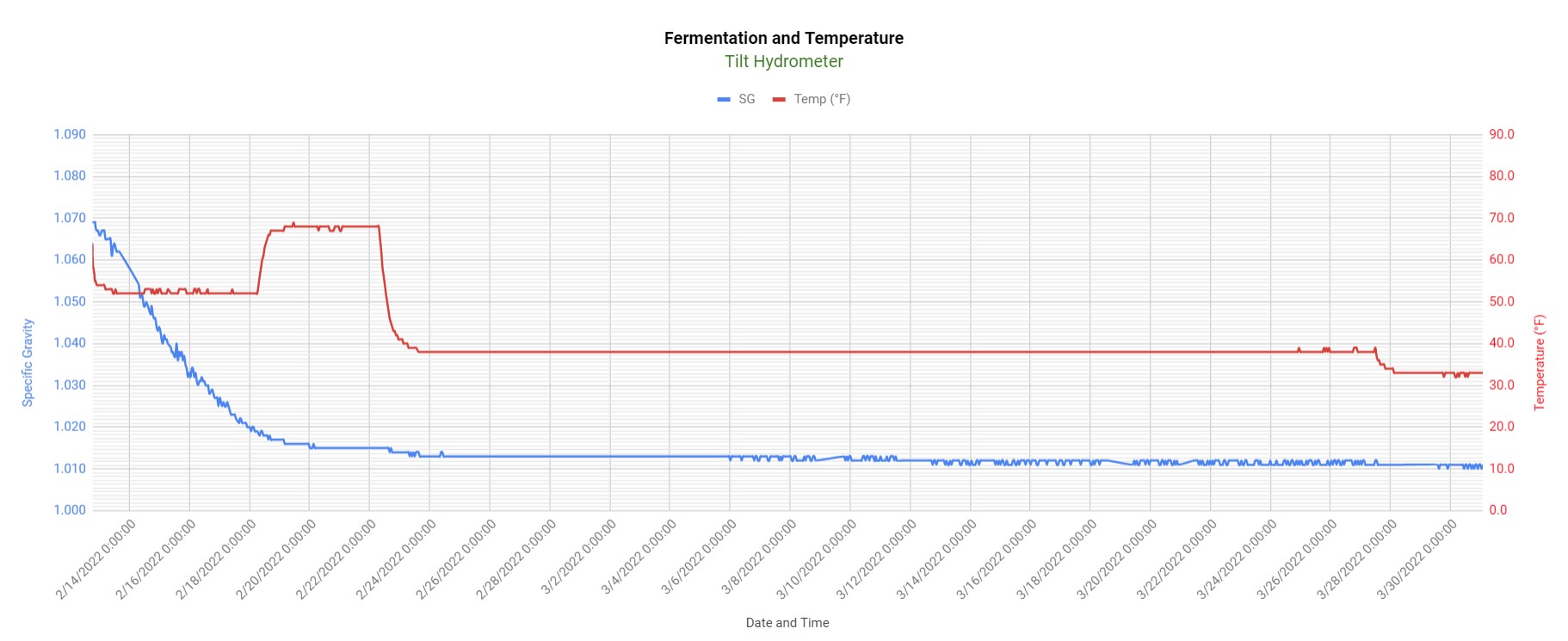

I always do a rest when brewing lagers . I start raising the temp a few degrees a day once it's 75% fermented. Once it's in the high 60's I leave it for 3 days . The Tilt comes in handy for this .

- Joined

- May 28, 2018

- Messages

- 3,265

- Reaction score

- 2,979

This is the first time with this recipe so I'm sure what the finishing gravity should be. This is the recipe Brewfather

I copied it from a YouTuber with a couple changes. I don't have it in front of me but I think the OG was 1.057.

Not a problem, I get SG 1.055-060 on regular basis.

Don't worry about sulfur taste when lager is that young.

A good lager takes patience, including 3-6 weeks cold crashed and lagered at around freezing temps. That is after 3-4 weeks of primary fermentation plus D rest. I carbonate by spunding, so that is a factor too. Is no extra effort, actually less, but I digress.

Normally my cold lagers are in primary for 7-12 days, depending on if original pitch or running batches cone to cone, then I keg, D rest & spund. Don't really go by time fermenting, a combo of airlock activity for rough idea and gravity tests during late fermentation trub dump(s) to determine when to ramp temp fpr D rest, clean up.

Generally I go to 64-5F for D rest until pressure stops building, but a week is OK if you're not monitoring that.

Sorry if a bit rambling, been drinking some fine lagers... Will re visit in morning...if further clarification is indicated.

Diacetyl tastes a bit like creamed corn, or so they say. I'm not so sure about that, but I can taste it. Sometimes it is subtle, and there are even some beers where it is intentional (like original Rolling Rock). I like to work all that out for a clean crisp taste. and am convinced there are other compounds that get worked out during D rest besides the diacetyl when going for a clean lager.Would I determine the need for a diacetyl rest by tasting/smelling? Would it hurt to do it if it doesn't need it? Right now it smells pretty sulphury. I brewed on Sunday but it was like 2 AM by the time I pitched.

Last edited:

Diacetyl tastes like butter. DMS tastes like corn… 2 very different things.Diacetyl tastes a bit like creamed corn, or so they say.

First off you need to determine if a d-rest is even needed.

I’ve never done this myself, but here’s the procedure…Would I determine the need for a diacetyl rest by tasting/smelling? Would it hurt to do it if it doesn't need it? Right now it smells pretty sulphury. I brewed on Sunday but it was like 2 AM by the time I pitched.

https://winning-homebrew.com/diacetyl-test.html

Unfortunately, I don't have a keg or fridge space to lager in bottles. I'm using a copper coil hooked to a pump in ice water. After the diacetyl rest should I lager on the yeast or transfer to secondary?

The airlock is bubbling once every four seconds, I'm gonna take a hydrometer reading tomorrow. While I was at work it went up to 60F I had my daughter swap out the ice bottles and it's back down to 52F now.

- Joined

- May 28, 2018

- Messages

- 3,265

- Reaction score

- 2,979

Sometimes I mix words up, esp when drinking, but rest assured I know what both are and how to avoid them.Diacetyl tastes like butter. DMS tastes like corn… 2 very different things.

- Joined

- May 28, 2018

- Messages

- 3,265

- Reaction score

- 2,979

After the D rest, one would normally bottle or keg the beer. No need for secondary. Then cold crash and store, or lager, cold. Sounds like you need another fridge!Unfortunately, I don't have a keg or fridge space to lager in bottles. I'm using a copper coil hooked to a pump in ice water. After the diacetyl rest should I lager on the yeast or transfer to secondary?

I keg the beer and then do D rest and spund, it works well for me with my set up. But many people do the D rest in primary and the bottle or keg. Either way works.

AZ Maverick

Well-Known Member

I use a Tilt Hydrometer during fermentation. I do the diacetyl rest near the end of primary fermentation just before it's finished. Then I lager and finally I fine with gelatin and then cold crash just above freezing. I usually always end up with a nice lager when I properly follow that program.

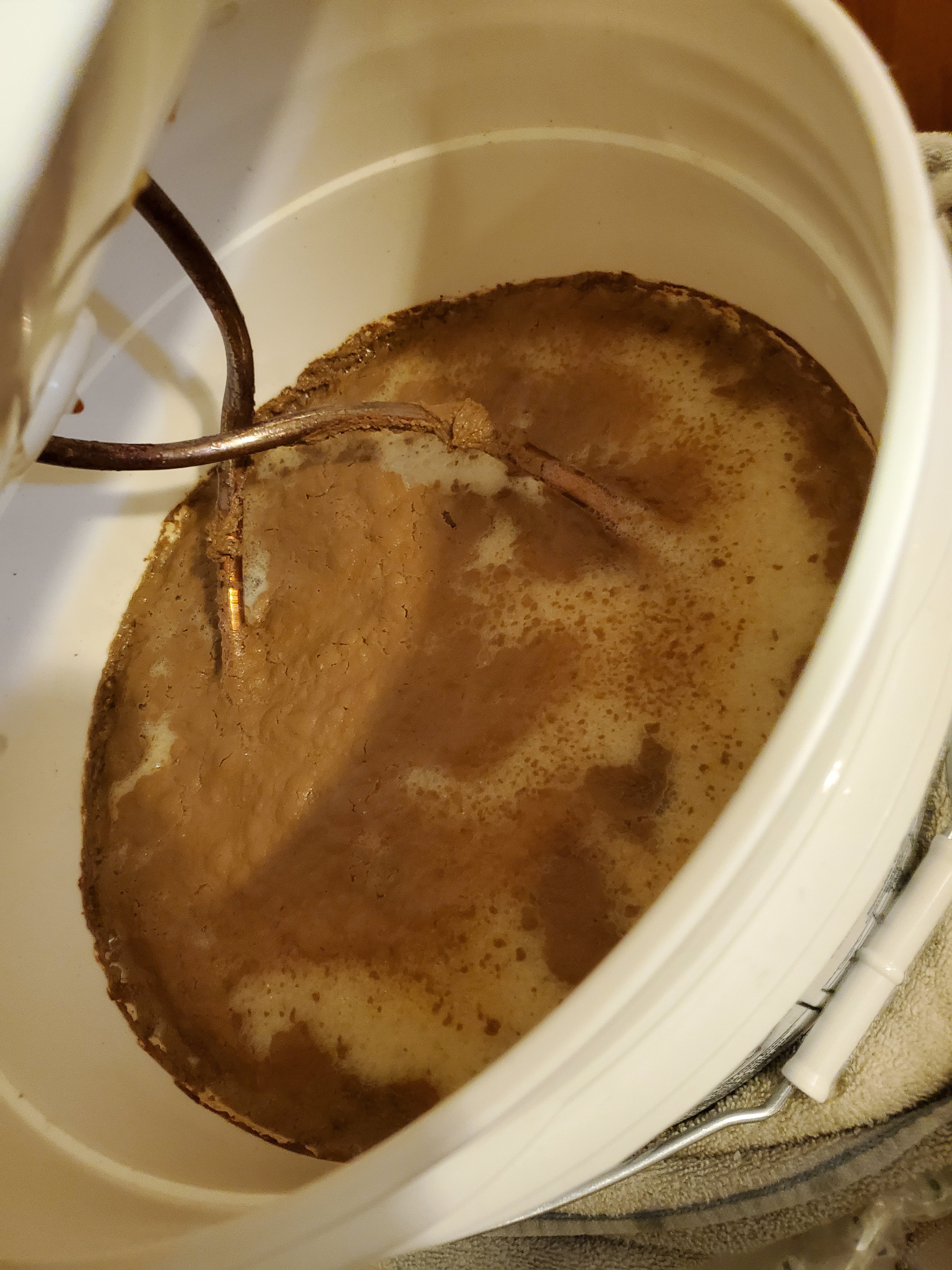

Here's a Maibock that I did a couple of months ago:

Here's a Maibock that I did a couple of months ago:

Agree, keg it and put it away for 6 months cold. Time to buy a small refrigerator to lager the beer.

This is the first time with this recipe so I'm sure what the finishing gravity should be. This is the recipe Brewfather

I copied it from a YouTuber with a couple changes. I don't have it in front of me but I think the OG was 1.057.

The linked recipe has an expected FG of 1.015, which is in the range for an Oktoberfest. Then I would revise my d-rest up into the 1.020-1.025 range, and others have started at higher gravities. Once the "high krausen" stage is ramping down, you should be good to start.

Last edited:

Unfortunately, I don't have a keg or fridge space to lager in bottles. I'm using a copper coil hooked to a pump in ice water. After the diacetyl rest should I lager on the yeast or transfer to secondary?

What type of packaging is this beer ultimately destined to reside in?

If no keg, and you are not currently using a pressurized fermenter, you will need to carbonate the beer in bottles at some point. No carbonation will occur in a non-keg secondary (or similar vessel) as it cannot hold 10+ PSI pressure.

Then, once the bottles are packaged, give them 2 weeks AT ROOM TEMP for the residual yeast to chomp on the priming sugar added to each bottle to build carbonation.

Homebrew is generally unpasturized, so it will need to be stored cold at all times until consumed from this point onward.

As others have mentioned, you will have need to stash up to 54 12oz bottles (or larger bottle equivalents) *somewhere* for the 2-weeks carbonation, and then a cold space/fridge.

While it may not fit the historical definition of "lagering" as we are not using caves, or altering our brew schedule due to seasons... this "sittin' in the fridge" cold storage is conditioning, lagering, etc nowadays. Lagers can sit in the cold and get better as the weeks go by. Enjoy!

If I lagered in secondary with the coil would it still carbonate if bottled or would the yeast have are dropped out at that point? Worst case scenario I lager the bottles in coolers but it would be easier to keep it one container. Whenever I've made ale I kept it in the basement, is the need for continued refrigeration lager specific?

Where did you get the chilling coil idea? Couple issues here, usually the bucket or carboy would be in an ice water bath. A copper chilling coil in contact with wort is not good as it can leach copper, that’s why stainless is used in wort contact not copper.

Also don’t open your lid, you don’t want beer oxidation at this stage.

Lots of bottle conditioned beers are unpasteurized. Cold storage is better, but they don’t have to be stored cold because they are unpasteurized. Cold storage helps retain flavor.

At bottling time, some people add some additional yeast to the bottling bucket if they are unsure of there being sufficient yeast. It doesn’t take much, your beer will carbonate fine.

Also don’t open your lid, you don’t want beer oxidation at this stage.

Lots of bottle conditioned beers are unpasteurized. Cold storage is better, but they don’t have to be stored cold because they are unpasteurized. Cold storage helps retain flavor.

At bottling time, some people add some additional yeast to the bottling bucket if they are unsure of there being sufficient yeast. It doesn’t take much, your beer will carbonate fine.

If I lagered in secondary with the coil would it still carbonate if bottled or would the yeast have are dropped out at that point? Worst case scenario I lager the bottles in coolers but it would be easier to keep it one container. Whenever I've made ale I kept it in the basement, is the need for continued refrigeration lager specific?

Skip the secondary process completely. As for the D rest, its a good idea to bring all lagers up to room temp at some point before packaging, just to be on the safe side. I'm sure there's a lot of science somewhere explaining why, and how, but for the rest of us, just warm it up a couple weeks after you pitched, for a day or three, and you'll be fine.

As for the aging process, if you can keep it at 35F or so for 3-6 weeks great, if not don't freak out, put it in bottles, do the best you can.

I use lagers yeast in my home brewery, for almost all of my beers. People seem to think there's some sort of voodoo for lagers, but there's not. To simplify, it's really just beer that's been fermented colder. I often times pitch lager yeast into an otherwise ale beer, and ferment it at 63F or so, and skip doing anything lager specific.

Your beer is going to be great, enjoy the ride and don't panic.

Yes a lot of wort chillers are copper. My first chiller was copper.I saw some for sale and then found some instructions online. I didn't think copper would be an issue because that's what my wort chiller is made out of.

I think the issue is long term exposure to slightly acidic wort. There are a number of articles online about this. Longer term exposure is the issue, not a quick chill down, you are OK there.

This time no biggie, just wanted to make you aware of it. That’s what this forum is for.

Similar threads

- Replies

- 8

- Views

- 1K

- Replies

- 13

- Views

- 2K