EnglishAndy

Well-Known Member

I'm doing my first high gravity BIAB brew next week and am looking for tips that'll help me to hit my target OG of 1.090.

I normally do 6 gallon brews in the 1.042 to 1.050 range and hit 80-85% BH efficiency. I crush my own grain with a 32 mil gap. I save back about 1.5 gallons for a 10 minute soak-the-bag sparge and I squeeze like it owes me money (which it does).

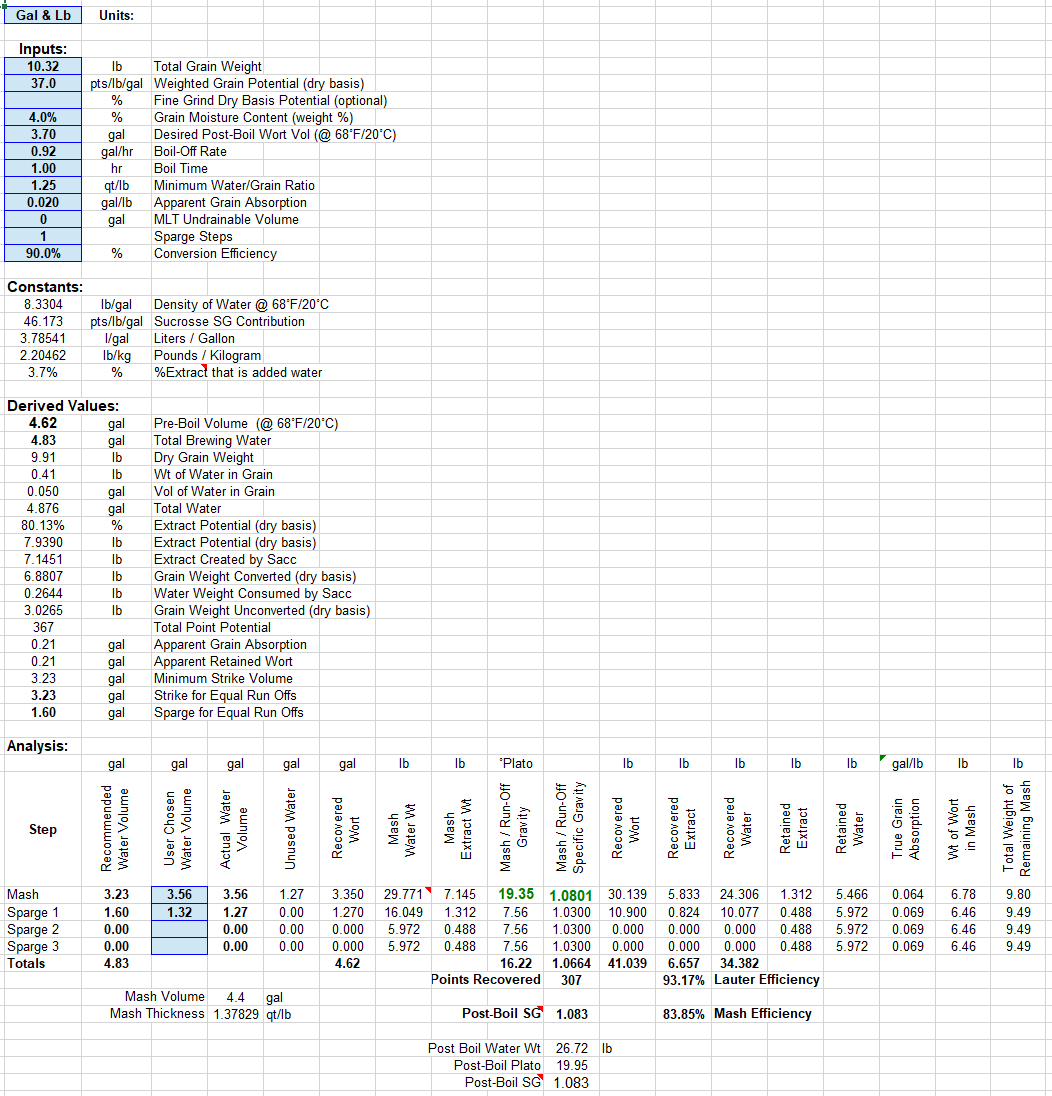

My 1.090 RIS will be a shorter brew length of 3 gallons and if I follow the usual procedure then I'll be mashing about 10lb of grain in 3.7 gallons of water and then doing my usual 1.5 gallon sparge before boiling for 60 minutes.

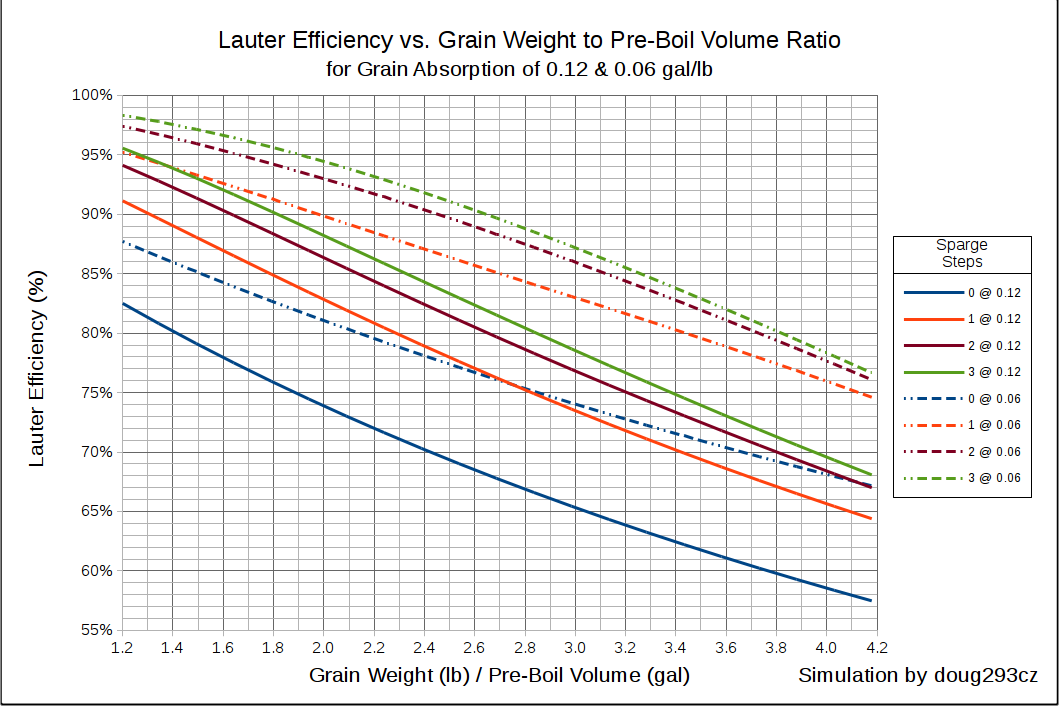

I've downgraded my recipe efficiency expectation from 80% to 75% already. Does this sound reasonable? What are your experiences with high gravity BIAB?

I normally do 6 gallon brews in the 1.042 to 1.050 range and hit 80-85% BH efficiency. I crush my own grain with a 32 mil gap. I save back about 1.5 gallons for a 10 minute soak-the-bag sparge and I squeeze like it owes me money (which it does).

My 1.090 RIS will be a shorter brew length of 3 gallons and if I follow the usual procedure then I'll be mashing about 10lb of grain in 3.7 gallons of water and then doing my usual 1.5 gallon sparge before boiling for 60 minutes.

I've downgraded my recipe efficiency expectation from 80% to 75% already. Does this sound reasonable? What are your experiences with high gravity BIAB?