Any other suggestions of skipping secondary?

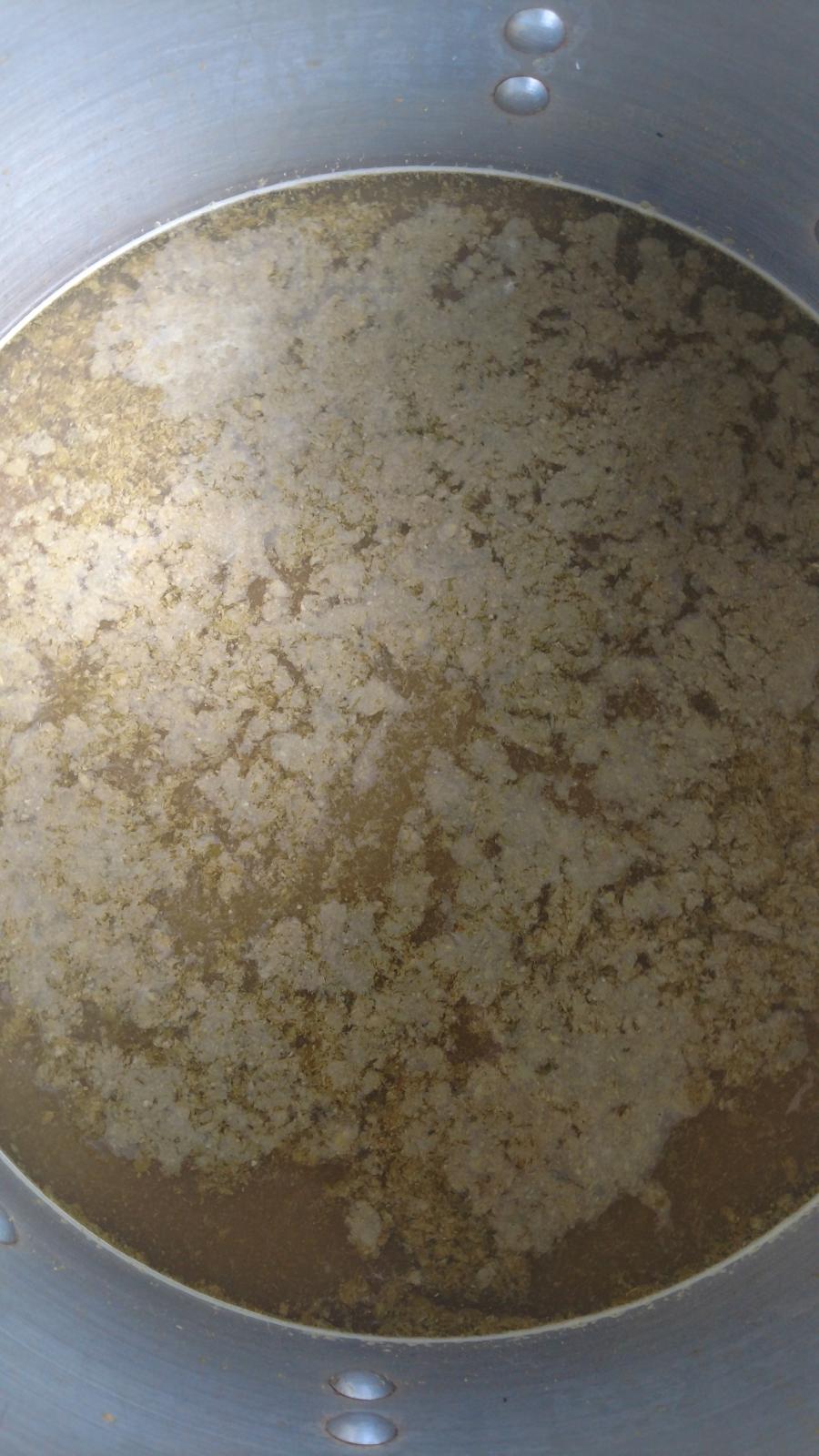

You can use secondary to clear it up for a few days, but that should be at least 3 wks after you have it in primary. If you really want to, after it is completely fermented, rack to secondary, put it in a cooler place for a couple days, then bottle. Just to get rid of some of the hop gunk and proteins to clear up that IPA

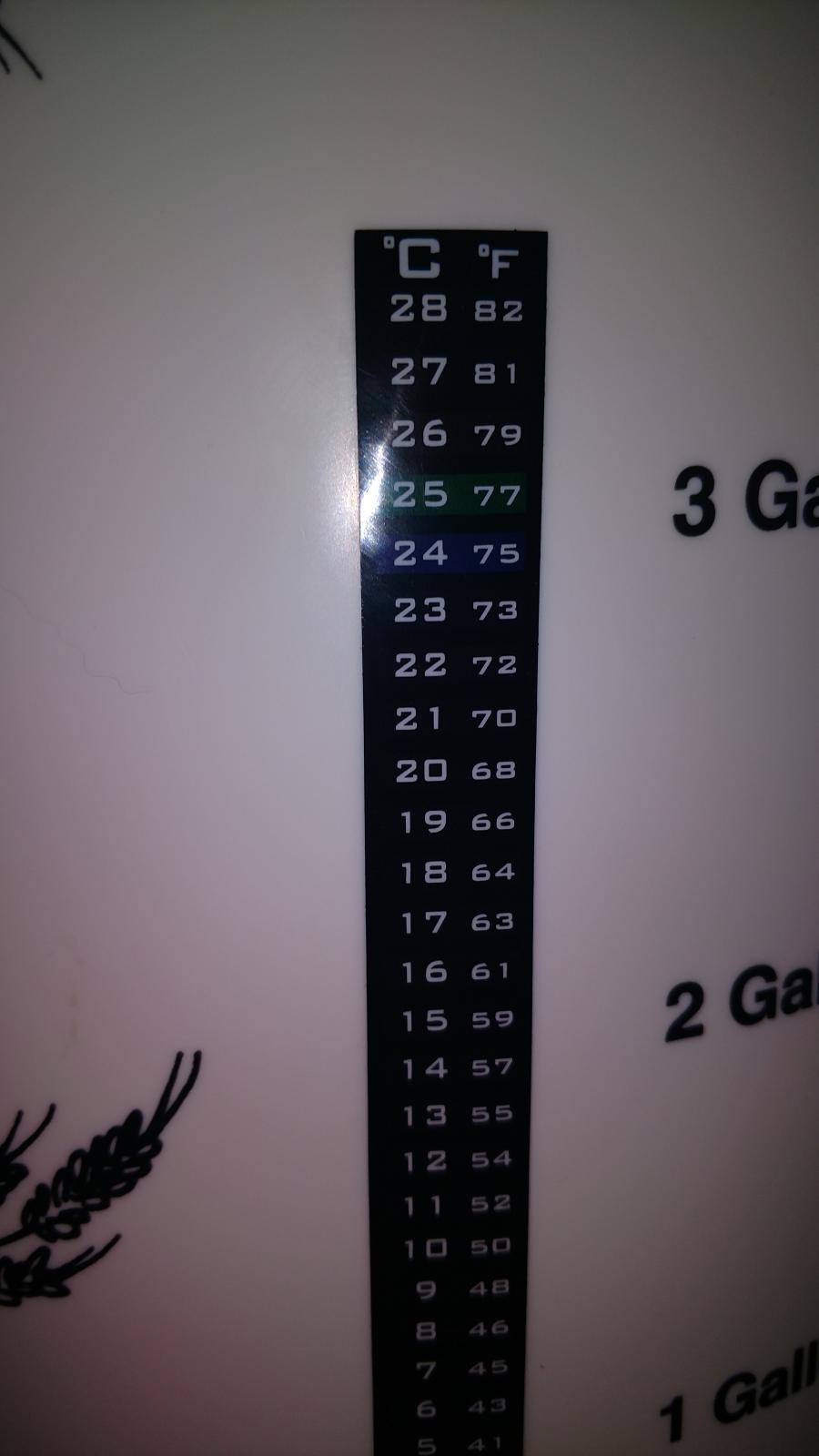

For the temp, do you have a large cooler or something to put that bucket in so you can get some ice water around it? That will lower the temp. The fermentation will cause it to heat up in the first few days then cool off as the yeast slow down, so ferm temp is not as critical later on for ale

Since you are fermenting on the high side, you should let the beer sit in primary at least 3 weeks to clean up some of the off flavors, but should be a good first beer!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)