There are two processes that affect your wort making efficiency, which is known as "Mash Efficiency" (BeerSmith), "Pre-Boil Efficiency" (BrewersFriend), and sometimes "Extract" or "Extraction" Efficiency (most often by pro-brewers.) The first process is saccharification, i.e. converting starch to sugar. This is characterized by "Conversion Efficiency." Conversion Efficiency is defined as the amount of sugar actually created in the mash divided by the maximum amount of potential sugar in the grain bill (and multiplied by 100% to give a percentage efficiency rather than a fractional efficiency.) The second process is separating the sugar from the grain, along with the water that makes up the wort. This process is called "Lautering", and is characterized by "Lauter Efficiency." Lauter Efficiency is defined as the amount of sugar that makes it into the boil kettle divided by the amount of sugar actually created during the mash. And finally, Mash Efficiency is equal to Conversion Efficiency times Lauter Efficiency.

Crush, mash time and to a lesser extent mash thickness and mash pH affect conversion efficiency. Finer crush, longer mash times, and reduced mash thickness can all have a positive affect on conversion efficiency. Lauter efficiency depends on whether or not you sparge, the grain absorption rate, and the the grain bill weight vs. the pre-boil volume. Sparging increases lauter efficiency by reducing the SG of the wort retained by the grain, thus reducing the amount of sugar retained. Reducing the grain absorption rate (by squeezing) reduces the amount of wort and sugar retained, thus improving lauter efficiency. A larger grain weight to pre-boil volume ratio decreases lauter efficiency because a larger percentage of the wort (sugar) gets retained by the grain.

This is primarily due to increased lauter efficiency from a reduced grain weight to pre-boil volume ratio, as explained above, and you mention in a later post.

If saccharification is incomplete (i.e. conversion is less than 100%), then a longer mash can definitely improve conversion efficiency by allowing more conversion to occur during the extended time. Once conversion has reached 100%, more time will not improve conversion efficiency, although it may allow more of the unfermentable sugars to be converted to smaller, fermentable ones.

Likewise a mash out will not improve conversion efficiency if conversion is already complete. If conversion is incomplete, the the mash out is really just providing extended mash time to allow more conversion, and at a faster conversion rate due to the higher temperature (until the enzymes are denatured.) If you are getting higher efficiency with a mash out, that is an indication that your mash is incomplete in the time you allowed.

Sparging can have a very large affect on lauter efficiency. If doing a pour over sparge, you should let the bag drain well prior to starting the sparge. The less wort in the grain when the sparge starts, the more effective the sparge will be.

Another option is a dunk (batch) sparge conducted by placing the grain bag in another pot/bucket, adding fresh water to the grain, stirring well, and then pulling and draining the bag again. Again, minimizing the amount of wort in the grain prior to the sparge will increase the efficiency of the sparge.

Starches can be gelatinized but still not soluble, and insoluble starches cannot be extracted (although some portion of any colloidally suspended starch my get lautered.) Starches have to be dissolved in the wort to be extracted. What's soluble is the shorter chain starches and sugars.

The saccharification process is more complicated than this. The original starch is for the most part insoluble, and there is essentially no sugar in the malt initially. Before you can convert starch to sugar, you need to surround the starch molecules with water, and this is called gelatinization. Gelatinization is the slowest step of the saccharification process, so it is the rate limiting step. Once the starch is gelatinized the amylase enzymes can start catalyzing the reaction of starch with water, which chops the starch chains into smaller starch chains and sugars. The smaller starch chains become soluble, and get dissolved into the wort where enzyme reactions can occur even faster. Dissolved starch molecules don't survive long in the wort if there are enzymes present. Incomplete conversion is primarily due to incomplete gelatinization of the grits. Since gelatinization starts at the surface of the grits and proceeds towards the center, the larger the grit, the longer it takes for the grit to completely gelatinize. This is the reason for the crush size effect on conversion efficiency.

Pretty good description. However, the higher SG of the wort doesn't really affect the lauter efficiency. The lower lauter efficiency is due to having proportionately more grain absorbing wort, thus a larger percentage of the total wort volume is held by the grain. If you collect 4 gal of wort and the grain retains 1 gal, your lauter efficiency is 80%, regardless of the wort SG.

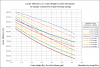

80% mash efficiency is possible with thinner mashes with no-sparge BIAB. But when doing higher gravity beers, the mash thickness tends to go up, so the lauter efficiency goes down. The chart below shows lauter efficiency for no-sparge and equal runnings batch sparge for several different grain absorption rates, over a range of pre-boil volume to grain weight ratios. This shows how large an effect squeezing (grain absorption ratio), and grain bill size have on lauter efficiency.

View attachment 373646

Brew on

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)