firedutyonly

Member

- Joined

- Mar 13, 2017

- Messages

- 19

- Reaction score

- 1

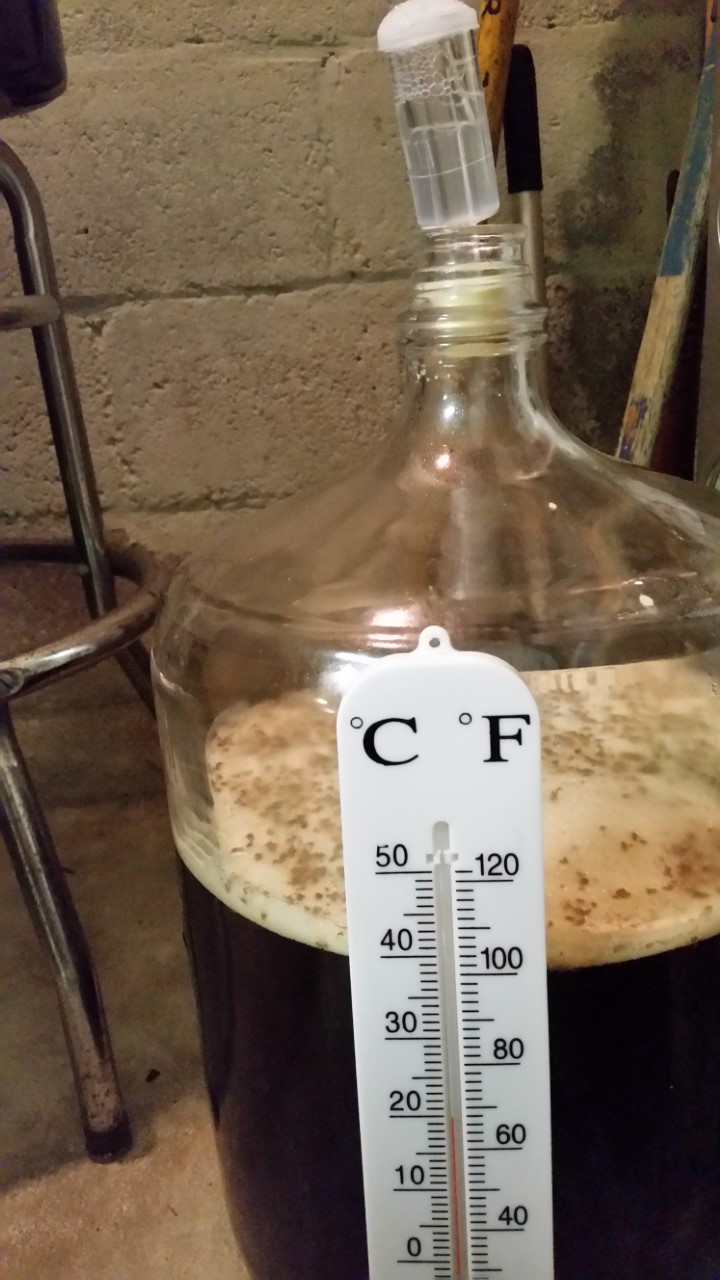

Followed recipe to the letter. Everything sanitized prior to beginning. Read the "book". Watched a ton of videos. About five visits to 3 different Homebrew stores. making Dunkelwizen. Controlled the heat perfectly, no boilovers. So.........all done boil. already had my stainless steel wort chiller in dyring last 10 mins of boil. I get the cold water flowing. Watching the temp gauge drop nicely....sounds good right? It hovered around 100...I'm tapping the thermometer, no change. I'm feeling the wastewater, still warm...wtf....found the issue(after about 15-20mins.)...I was using my outside stall shower as water source and had hot and cold turned on accidentally. quickly turned off the hot and temp dropped. I'm not sure how long it was before I moved it to Glass Carboy. But I kinda defeated the whole purpose of the wort chiller. On top of everything, when

I placed the stopper and airlock, I pushed it in too far...Lil bit more and it will fall in. This morning,(brewed last night around7 PM) I went into basement and check , it is beginning to bubble a bit, and it looks like some Krausen on top starting. Is there any way I can get that stopper out when I move to secondary? If it falls in it will contaminate the batch, correct?. What about the extended cool down period? Help and Thanks

I placed the stopper and airlock, I pushed it in too far...Lil bit more and it will fall in. This morning,(brewed last night around7 PM) I went into basement and check , it is beginning to bubble a bit, and it looks like some Krausen on top starting. Is there any way I can get that stopper out when I move to secondary? If it falls in it will contaminate the batch, correct?. What about the extended cool down period? Help and Thanks