The dry hops adding, this will not introduce possible bacteria? Thanks for the tips!

The alcohol in the beer is a deterrent to invaders, as is the low pH. Hops themselves are antiseptic, just adding them to the beer is fine, especially pellets and cryo hops. For example, Lactobacillus can't thrive in beer over 10-15 IBU, most beers qualify, certainly IPAs.

Now if you drop the dry hops on your garage floor, sweep the lot up in a dust pan and pour them down a funnel that is normally used to fill small plant pots with dirt, you're on your own. But we still like to hear and see all about it, the technique, the results, the pellicles. All of it! We really like beer drama as much as beer itself. No, we need it!

Dry hopping:

Lacto may not thrive in hoppy beers, there are others bugs, though... that's why we still sanitize things before dry hopping.

Sanitation is very important, sure.

Clean, then sanitize everything well that touches chilled wort (<140F) and your beer. FWIW, wort becomes beer as soon as you

pitch yeast.

Before removing the stopper with the airlock, spray or mop Starsan around the stopper and the top of the lid on your carboy.

Just wipe the outside of the hop bag and scissors with a small Starsaned washcloth (mopping, dunking, and spraying are the best ways to sanitize), and pour the content into your fermenter. Or if you need a smaller amount, weigh out into a clean plastic Solo cup or so, Starsaned then dried out.

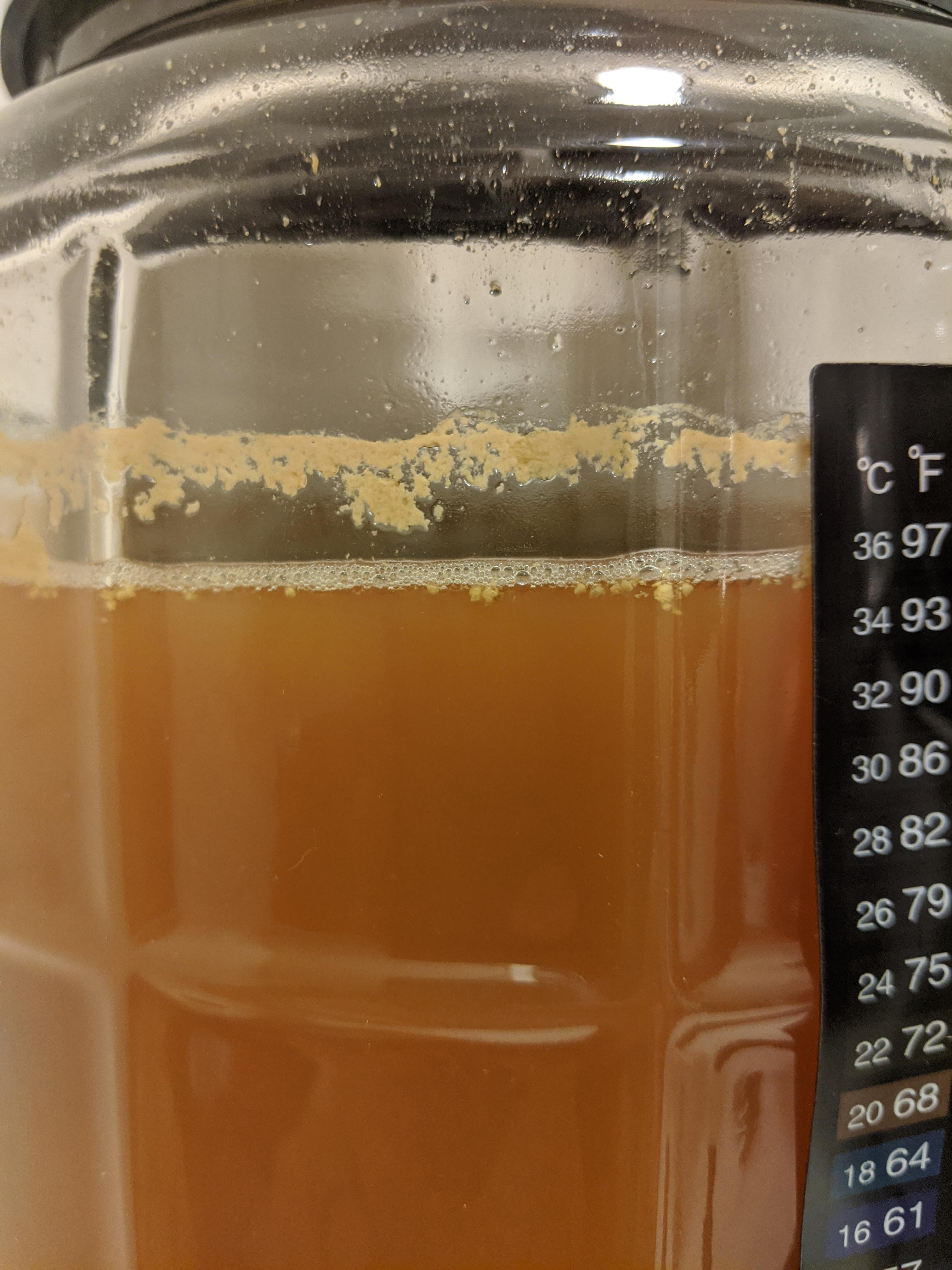

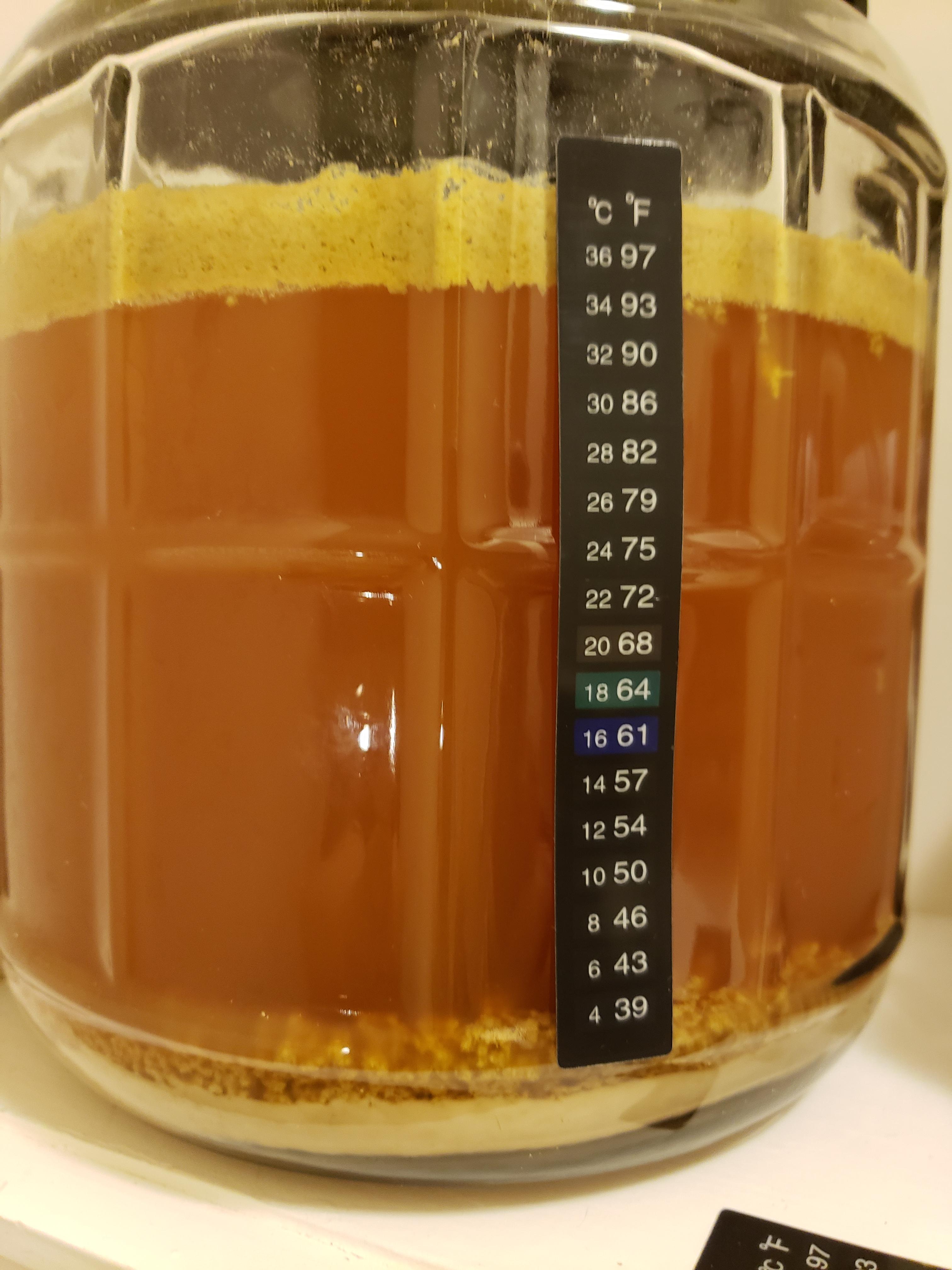

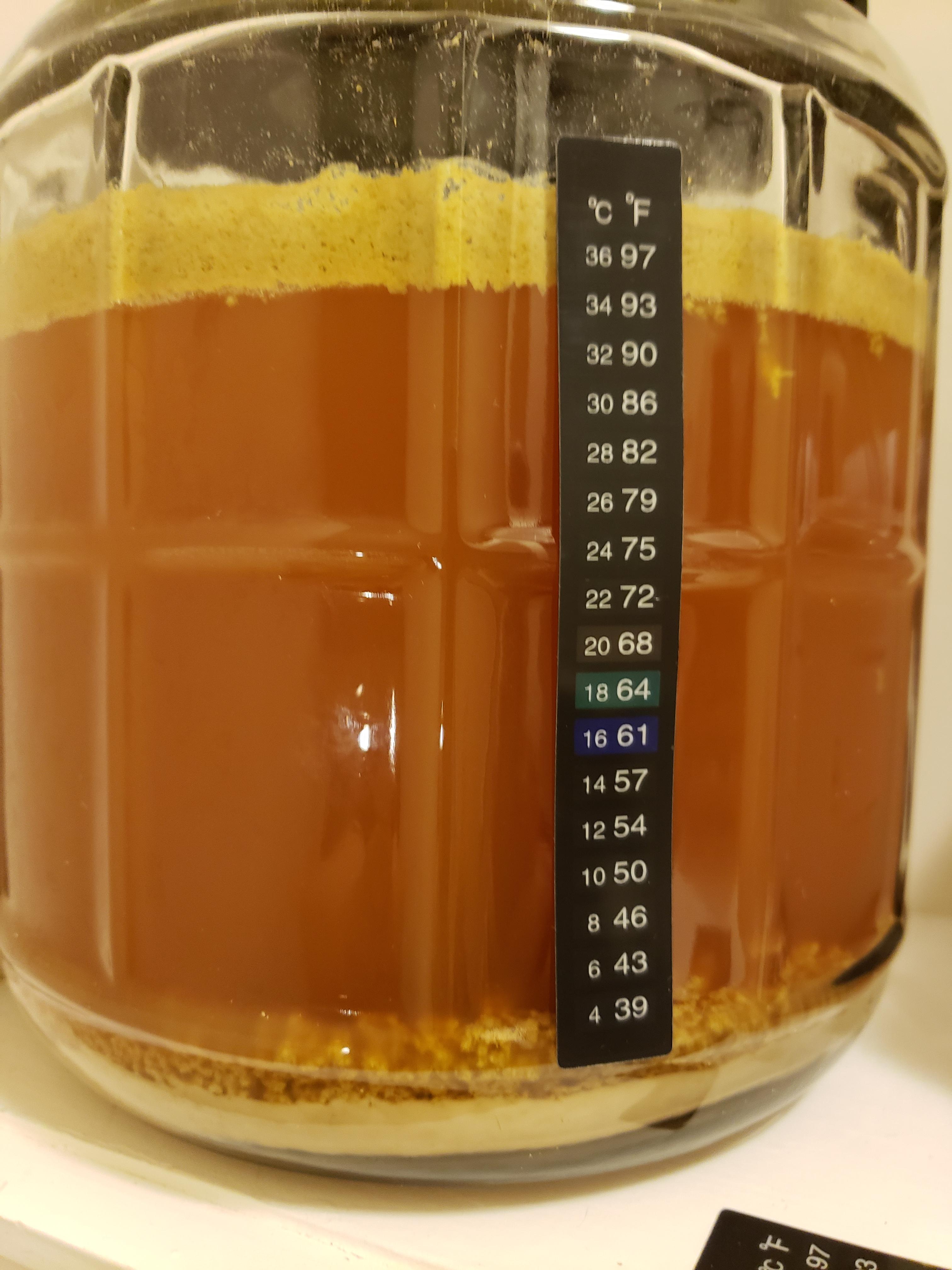

After adding the dry hops, I find some sort of agitation such as carefully swirling the fermenter (or stirring the beer, gently), at least once a day, until all the pulp has submerged gets quicker (and possibly better, more complete) extraction. I can give you more details about that if you want.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)