DeathSausage

New Member

2 weeks ago I purchased a cooler mash tun and keggle from a guy who was getting rid of all his equipment. Last week, I decided to try my very first all-grain brew now that I had the stuff to do it... It was a cream ale that is doing very well in fermentation and looks like it's going to be great.

https://picasaweb.google.com/bretweaver4/Desktop?authkey=Gv1sRgCJHjvbfszY7RpwE#5619634054935831106

The problem was, my first mashing experience was far from flawless. I made about all of the mistakes I probably could have. Opened the valve full to take my first runnings and resulted in a stuck mash. After stirring and waiting another 15 minutes for the grains to settle, I was able to get my runnings to come through but developed some serious channeling after I batch sparged. I believe this was due to the screen setup inside the tun itself.

https://picasaweb.google.com/bretweaver4/Desktop?authkey=Gv1sRgCJHjvbfszY7RpwE#5619633604767614098

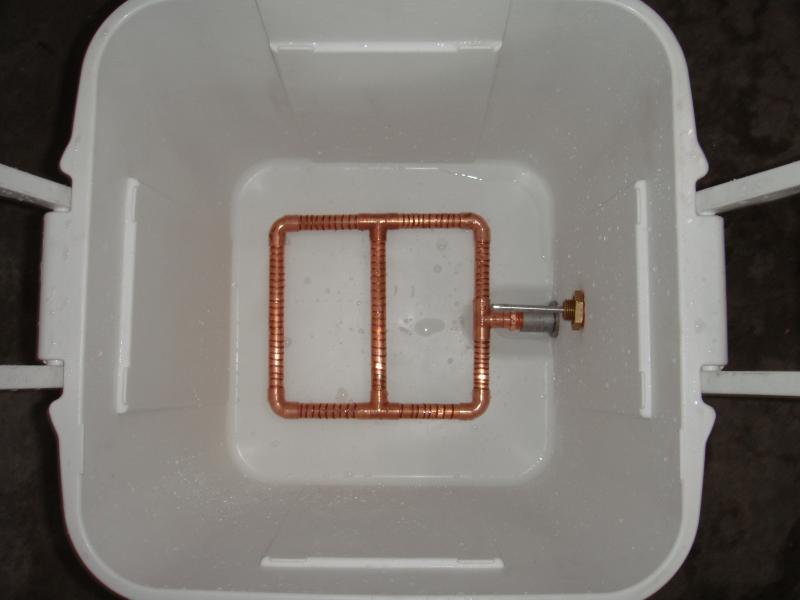

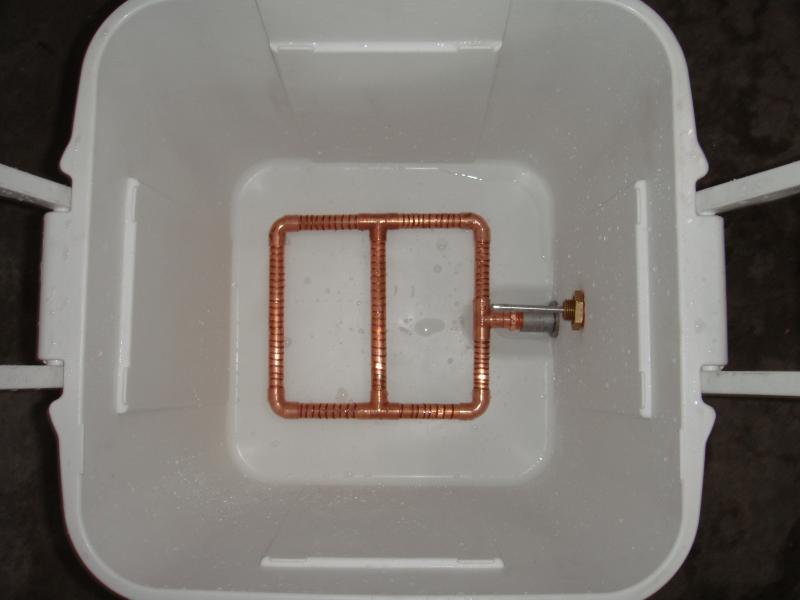

So, naturally, I decided that I should build a copper manifold to rectify the issue. I think this should work pretty well based on what I've seen but, due to the dimensions of the cooler itself I'm a little concerned about how small it is. I couldn't make it any bigger and still have the same distance from the cooler wall to the manifold all the way around (constrained by how far the pipe fitting comes into the cooler). My thinking is it will be at least as good as the screen I had before but would love some thoughts.

]https://picasaweb.google.com/bretweaver4/Desktop?authkey=Gv1sRgCJHjvbfszY7RpwE#5619633557477529538

https://picasaweb.google.com/bretweaver4/Desktop?authkey=Gv1sRgCJHjvbfszY7RpwE#5619634054935831106

The problem was, my first mashing experience was far from flawless. I made about all of the mistakes I probably could have. Opened the valve full to take my first runnings and resulted in a stuck mash. After stirring and waiting another 15 minutes for the grains to settle, I was able to get my runnings to come through but developed some serious channeling after I batch sparged. I believe this was due to the screen setup inside the tun itself.

https://picasaweb.google.com/bretweaver4/Desktop?authkey=Gv1sRgCJHjvbfszY7RpwE#5619633604767614098

So, naturally, I decided that I should build a copper manifold to rectify the issue. I think this should work pretty well based on what I've seen but, due to the dimensions of the cooler itself I'm a little concerned about how small it is. I couldn't make it any bigger and still have the same distance from the cooler wall to the manifold all the way around (constrained by how far the pipe fitting comes into the cooler). My thinking is it will be at least as good as the screen I had before but would love some thoughts.

]https://picasaweb.google.com/bretweaver4/Desktop?authkey=Gv1sRgCJHjvbfszY7RpwE#5619633557477529538

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)