CollinsBrew

Well-Known Member

Mounted the control box tonight. I wanted it to be able to fold out of the way so I put it on hinges and oriented the control box so that it would take up no more than the actual footprint of the brewstand.

The Temperature probes:

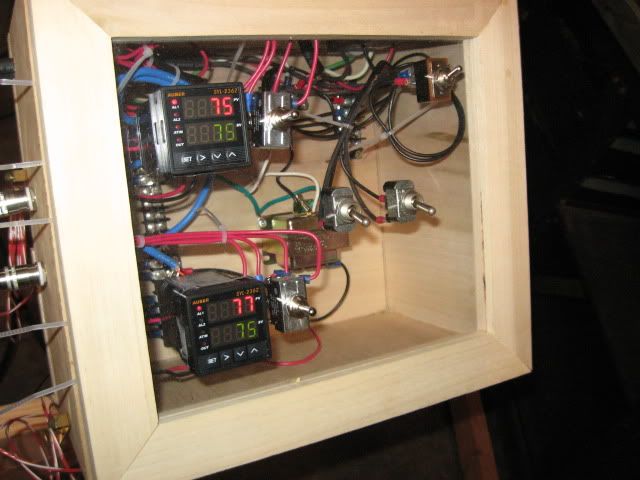

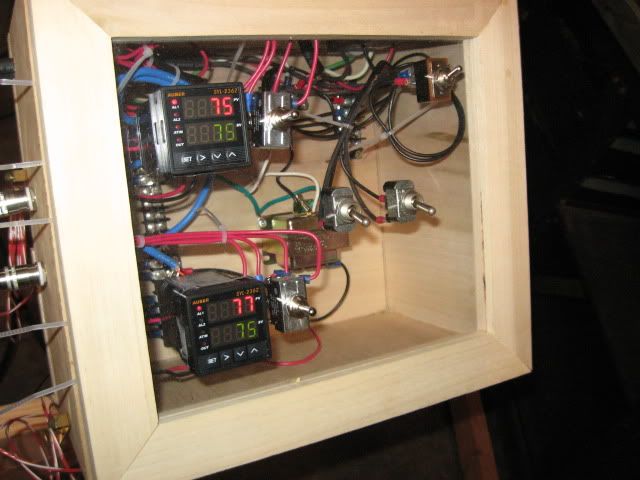

Control box lit up:

With the control box stowed away:

Had to cut out the top a little to have it fit flush:

The Temperature probes:

Control box lit up:

With the control box stowed away:

Had to cut out the top a little to have it fit flush:

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)