Hi

I've only been brewing for a couple of years and taken it as seriously as I can afford too over the last year so still really new to it. I mostly brew on a 20 litre braumeister.

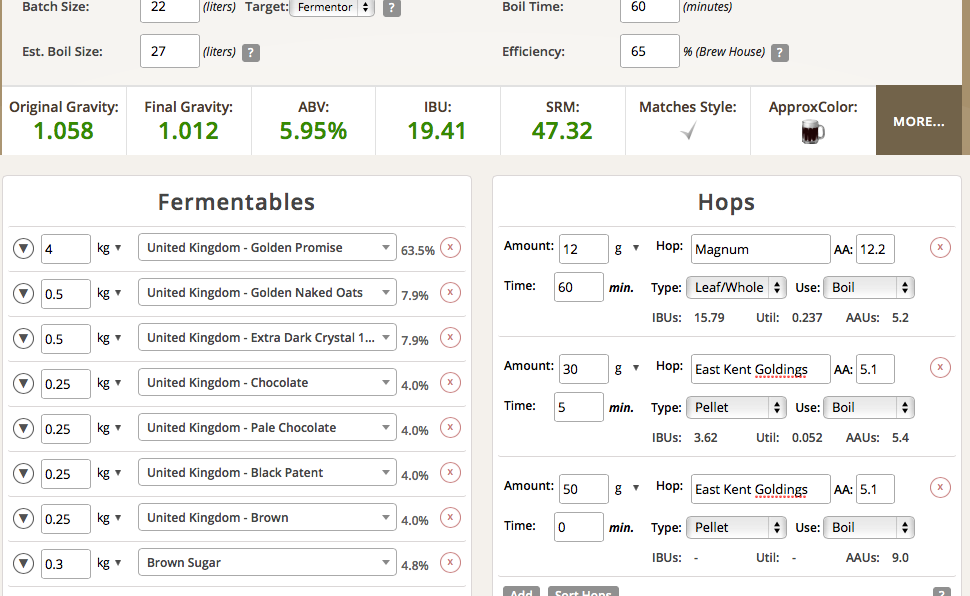

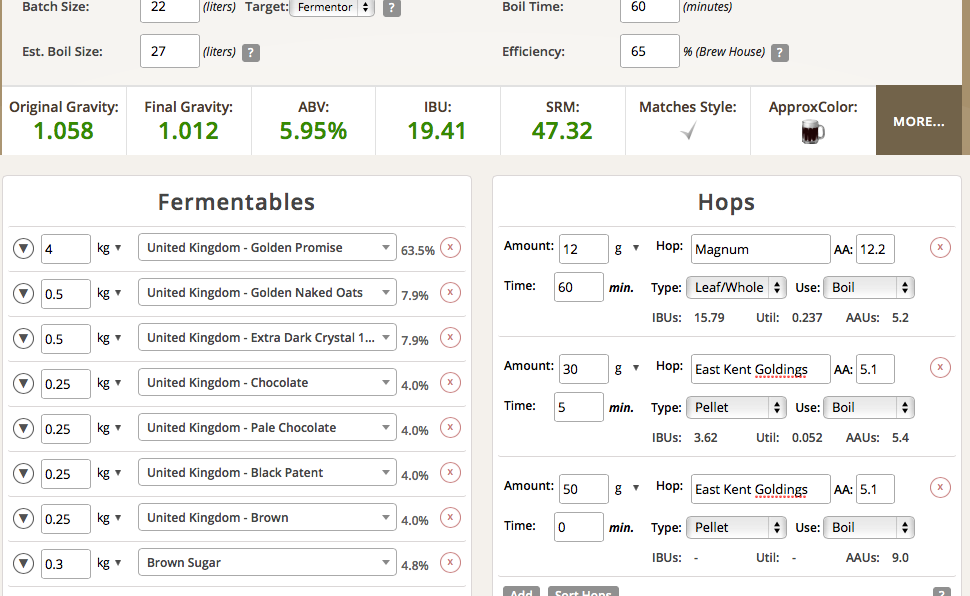

I recently brewed the attached recipe. Had some issues with hitting the OG and in fact in the original recipe the OG was 1065 with a efficiency of 70%, but think it was more like 65% so I reentered it.

I mashed at 68c for 70 mins and used Safale S05 but was only able to hit an FG of 1018/1020(Hard to read from the hydrometer) but lets say 1020.

Must confess I bottled it after 13 days. I tested the FG over two days and it was exactly the same. I have an 8 week year old baby so time is tight and brew at a brew club so not at home. A bad excuse I know but it did seem to have finished.

I'm a bit concerned now that I've bottled too early. I slightly underprimed it with a co2 level of 2 so hoping it will be ok. Just concerned of bottle bombs and wondered what the consensus on here was?

I've done a bit of research and it seems I was pushing the enzymatic power somewhat with the amount of specialty malt in the recipe and non fermentables. That with the higher mash temp might explain the FG?

i ferment at ambient temp of 18c.

Thanks for your help

I've only been brewing for a couple of years and taken it as seriously as I can afford too over the last year so still really new to it. I mostly brew on a 20 litre braumeister.

I recently brewed the attached recipe. Had some issues with hitting the OG and in fact in the original recipe the OG was 1065 with a efficiency of 70%, but think it was more like 65% so I reentered it.

I mashed at 68c for 70 mins and used Safale S05 but was only able to hit an FG of 1018/1020(Hard to read from the hydrometer) but lets say 1020.

Must confess I bottled it after 13 days. I tested the FG over two days and it was exactly the same. I have an 8 week year old baby so time is tight and brew at a brew club so not at home. A bad excuse I know but it did seem to have finished.

I'm a bit concerned now that I've bottled too early. I slightly underprimed it with a co2 level of 2 so hoping it will be ok. Just concerned of bottle bombs and wondered what the consensus on here was?

I've done a bit of research and it seems I was pushing the enzymatic power somewhat with the amount of specialty malt in the recipe and non fermentables. That with the higher mash temp might explain the FG?

i ferment at ambient temp of 18c.

Thanks for your help

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)