Good News // Bad News // Next Step.

Good News:

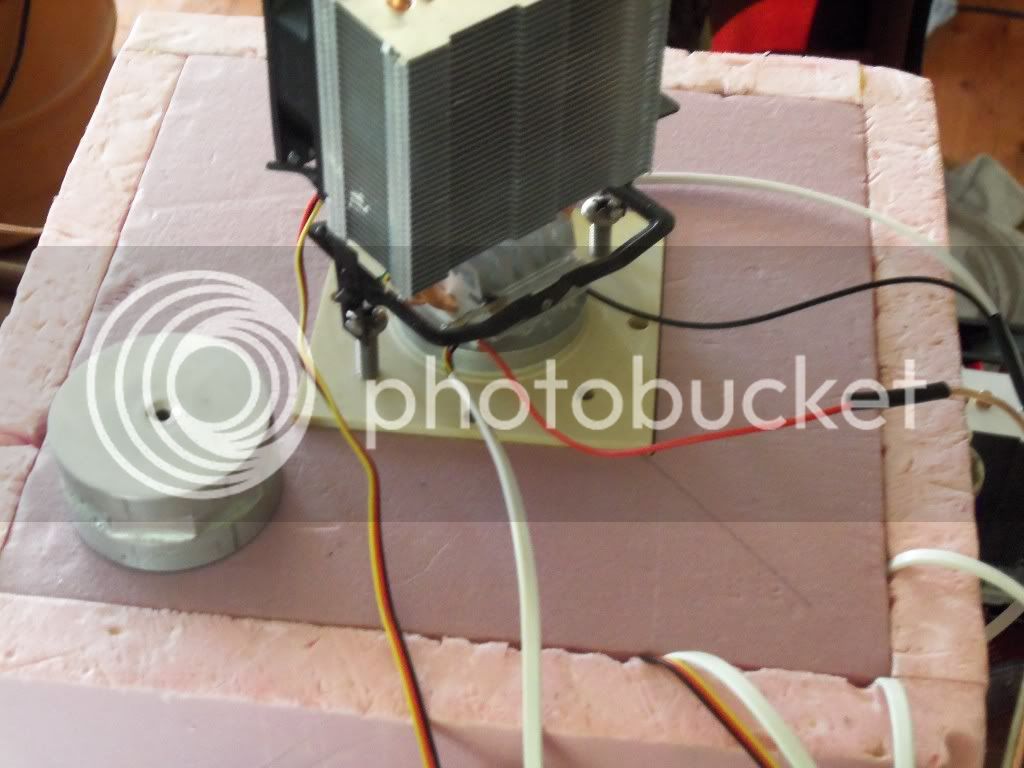

The simple/cheap TEC set up with just a piece of aluminum and two PC cooling fans cools almost effectively as the liquid transfer version (pump/radiator/fan). It pulls the H2O temp down to ~3.5C (38.3F) at almost exactly the same rate as the liquid transfer system....

Bad News:

The simple/cheap version has nearly 3x the heat gain into the box when the TEC is off. This result is more dramatic than I had hoped, but not unreasonable. The aluminum round stock used to remove the heat from the box when the TEC is on works just as effectively at transferring heat back into the box when the TEC is off.

Next Step:

The fact that the simple/cheap system introduces heat @ 3x the rate of the liquid transfer system is NOT a "deal breaker" in and of itself; however, it does require some "re-thinking". The list of possible "work-arounds" include:

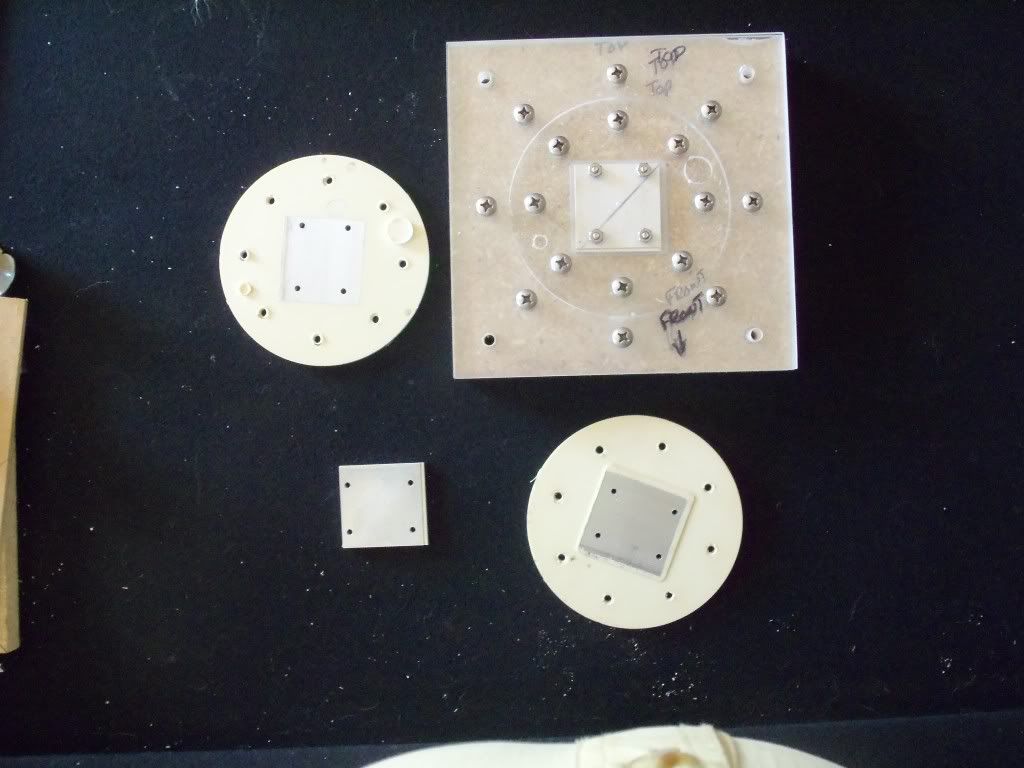

1) Move the TEC to "inside" the insulation between ambient and the box; ie, isolating the TEC from both ambient and controlled spaces. The hope would be that the thermal resistance of the TEC itself would decrease the heat transfer when the TEC is off.

2) Use PWM to maintain a nominal temperature difference across the TEC instead of going to a true "off state". This may sound like a waste of energy (and it is compared to the liquid transfer system), but the amount of power is fairly trivial compared to the cost of the liquid transfer system. We would simply use feedback from the cold sink sensor to ensure the cold sink stayed within 2C of the target temperature. In the rather extreme case of ambient = 22C, box temp = 3.5C, the heat gain into the box through the cold sink is ~5.45W. If the TEC is maintained @ a dT of ~18C with a dQ = 0 then this would effectively eliminate heat transfer through the cold sink. The math suggests it would take between 10W and 20W input into the TEC to achieve this, but I have not worked all the way through it to see if this is more/less/same total power consumption than simply using On/Off. The problem is even with only 1L of H2O a "simple test" takes 12 hours or longer of logging then a bit of time to format the data and evaluate the results....

3) Re-Evaluate the intended purpose of the system, energy consumption and goals. That is, if the goal is to maintain 19C in a 20C to 25C environment then the simple/cheap configuration is perfectly adequate. If the goal is to maintain 5C in a 30C to 40C environment then it is almost certain the liquid transfer system will be required. Simply design two different versions.

I am going to start designing and building solution #1 today, and hopefully will have it ready to test in the next few days; regardless of the results I am going to begin "big box testing" with the liquid transfer system very soon. (In fact, I may set it up first.)

Thanks for reading,

Fish

Good News:

The simple/cheap TEC set up with just a piece of aluminum and two PC cooling fans cools almost effectively as the liquid transfer version (pump/radiator/fan). It pulls the H2O temp down to ~3.5C (38.3F) at almost exactly the same rate as the liquid transfer system....

Bad News:

The simple/cheap version has nearly 3x the heat gain into the box when the TEC is off. This result is more dramatic than I had hoped, but not unreasonable. The aluminum round stock used to remove the heat from the box when the TEC is on works just as effectively at transferring heat back into the box when the TEC is off.

Next Step:

The fact that the simple/cheap system introduces heat @ 3x the rate of the liquid transfer system is NOT a "deal breaker" in and of itself; however, it does require some "re-thinking". The list of possible "work-arounds" include:

1) Move the TEC to "inside" the insulation between ambient and the box; ie, isolating the TEC from both ambient and controlled spaces. The hope would be that the thermal resistance of the TEC itself would decrease the heat transfer when the TEC is off.

2) Use PWM to maintain a nominal temperature difference across the TEC instead of going to a true "off state". This may sound like a waste of energy (and it is compared to the liquid transfer system), but the amount of power is fairly trivial compared to the cost of the liquid transfer system. We would simply use feedback from the cold sink sensor to ensure the cold sink stayed within 2C of the target temperature. In the rather extreme case of ambient = 22C, box temp = 3.5C, the heat gain into the box through the cold sink is ~5.45W. If the TEC is maintained @ a dT of ~18C with a dQ = 0 then this would effectively eliminate heat transfer through the cold sink. The math suggests it would take between 10W and 20W input into the TEC to achieve this, but I have not worked all the way through it to see if this is more/less/same total power consumption than simply using On/Off. The problem is even with only 1L of H2O a "simple test" takes 12 hours or longer of logging then a bit of time to format the data and evaluate the results....

3) Re-Evaluate the intended purpose of the system, energy consumption and goals. That is, if the goal is to maintain 19C in a 20C to 25C environment then the simple/cheap configuration is perfectly adequate. If the goal is to maintain 5C in a 30C to 40C environment then it is almost certain the liquid transfer system will be required. Simply design two different versions.

I am going to start designing and building solution #1 today, and hopefully will have it ready to test in the next few days; regardless of the results I am going to begin "big box testing" with the liquid transfer system very soon. (In fact, I may set it up first.)

Thanks for reading,

Fish