Hi everyone,

I'm new to brewing and tried to make a first batch which was a failure... I actually have no idea why and I hope that some of you might know why.

1. We followed the recipe and waited for the wort to cool down (around 22C a recommended) before adding the yeast. Then we sealed the fermentation pot.

2. I'm in Thailand, so the average temperature is quiet high, my solution was to use a cooler like this with a waterproof pocket where i put ice and water. I changed the ice every 12h and the water temperature was between 20 and 24C as recommended :

3. The fermenting pot was sealed, and no contact with extern air is possible, because when pushing on the cap the air lock start bubbling :

4. After 48h, no krausen and bubbling, i decided to add more yeast and when opening it smelled bad... 48h again later, no krausen.

5. Yesterday, there were rot in the pot, so i threw everything away . There was also some residues in the bottom:

6. Last thing, i realized that closing the cooler pushed a little bit the airlock down, making air in the fermenter go away.

So what could have possibly go wrong here ? What should i do next time to nail my batch ?

Thanks for all your answers guys !!

I'm new to brewing and tried to make a first batch which was a failure... I actually have no idea why and I hope that some of you might know why.

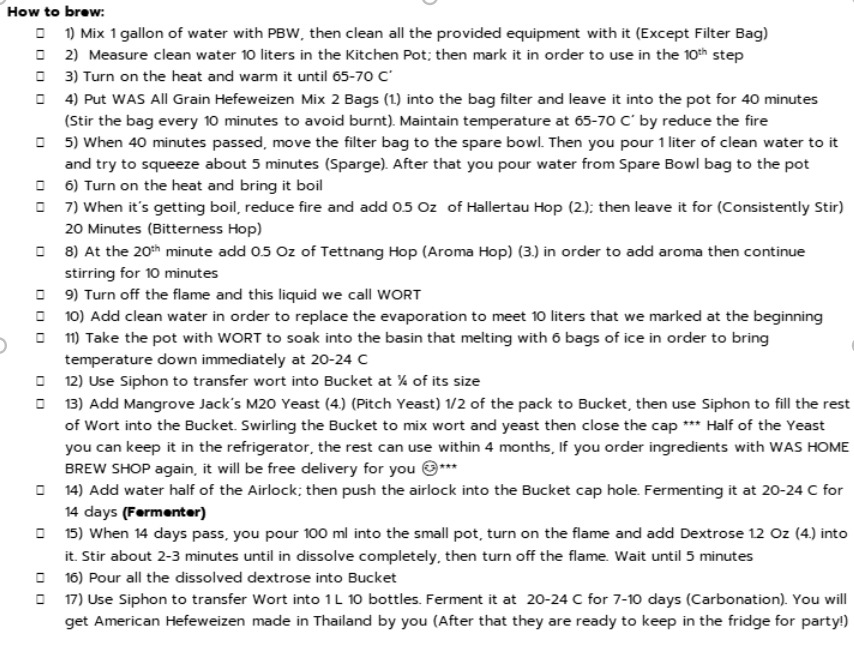

1. We followed the recipe and waited for the wort to cool down (around 22C a recommended) before adding the yeast. Then we sealed the fermentation pot.

2. I'm in Thailand, so the average temperature is quiet high, my solution was to use a cooler like this with a waterproof pocket where i put ice and water. I changed the ice every 12h and the water temperature was between 20 and 24C as recommended :

3. The fermenting pot was sealed, and no contact with extern air is possible, because when pushing on the cap the air lock start bubbling :

4. After 48h, no krausen and bubbling, i decided to add more yeast and when opening it smelled bad... 48h again later, no krausen.

5. Yesterday, there were rot in the pot, so i threw everything away . There was also some residues in the bottom:

6. Last thing, i realized that closing the cooler pushed a little bit the airlock down, making air in the fermenter go away.

So what could have possibly go wrong here ? What should i do next time to nail my batch ?

Thanks for all your answers guys !!

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)