Ran my first mash on ezboil Saturday and it worked like a champ. Can't wait to run all three vessels on them.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

EZboil, Power Regulator for Boiling DSPR110

- Thread starter Traz1986

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

BeardedBrews

Well-Known Member

Any of you guys have thoughts on the $20 to add the 0.1F resolution on the controller by going to the DSPR210?

http://www.auberins.com/index.php?main_page=product_info&products_id=559

http://www.auberins.com/index.php?main_page=product_info&products_id=559

The_Bishop

Well-Known Member

- Joined

- Dec 8, 2013

- Messages

- 2,100

- Reaction score

- 676

You only get that resolution in distilling mode, not mashing mode. I think the firmware is different in regards to boiling, etc.

BeardedBrews

Well-Known Member

You only get that resolution in distilling mode, not mashing mode. I think the firmware is different in regards to boiling, etc.

Well, that solves that dilemma.

Islandboy85

Well-Known Member

Any of you guys have thoughts on the $20 to add the 0.1F resolution on the controller by going to the DSPR210?

http://www.auberins.com/index.php?main_page=product_info&products_id=559

Probably better off improving your mash tun and plumbing insulation.

Beernip

Well-Known Member

Got an email from Auberins asking if I'd like to upgraded my backordered DSPR120 to a DSPR300. The DSPR300 comes with two relays for an alarm trigger... Perfect.

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$159.99 ($26.66 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

SpaceCityProviders

The DSPR300 looks pretty sexy from the description, it appears the relays are programmable to the point where you could operate some fairly sophisticated processes.

BeardedBrews

Well-Known Member

The DSPR300 looks pretty sexy

Man! You aren't kidding. They didn't just add an alarm relay, they added two brand new programmable outputs and they kept the internal alarm.

If I wasn't tempted to ditch my basic PID before, this looks awesome! I could automatically heat to Strike using 240v and then use one of the new relays to flip a contactor over to 120v when I am over 145.

I took out 2 of my pids and am using DSPR1 for the boil and the DSPR120 for the mash and loving both, they keep a better control and easier to change than a pid, I don't use any alarm or lights so the DSPR120 it fine, did a test yesterday and kept the mash to whatever I wanted up or down using the herms, only tested a few degrees up or down I know water isn't the same as wort

Hey all,

I'm in the process of planning and building out a 5g 120v eBIAB setup where I will likely use my stove top to boost temps for strike water heating and bringing things up to a boil. I dont have easy access to 240v and live in a smaller downtown apartment. I don't know much about electrical work and really like the looks of the small and clean Brausupply 120v controllers. the 120v Brausupply units now come with either a PID or EZBoil controller. Cost is about the same. I am looking at the setup as below, with the heating element to be controlled with a 120v controller, would you recommend the EZboil or PID model based on your experiences? Thanks for any help with the desicion!

10g Spike kettle with custom 1.5" TC ferrules

--TC side pickup tube

--TC whirpool return

--TC heating element port with 240v (for lower wat density) integrated TC elelment from brewsupply

--Second TC heating element port in case I want to go all electric later using 120v and can double as probe port

March pump for recirculation

silicone tubing with camlock fittings

Voile BIAB bag

I'm in the process of planning and building out a 5g 120v eBIAB setup where I will likely use my stove top to boost temps for strike water heating and bringing things up to a boil. I dont have easy access to 240v and live in a smaller downtown apartment. I don't know much about electrical work and really like the looks of the small and clean Brausupply 120v controllers. the 120v Brausupply units now come with either a PID or EZBoil controller. Cost is about the same. I am looking at the setup as below, with the heating element to be controlled with a 120v controller, would you recommend the EZboil or PID model based on your experiences? Thanks for any help with the desicion!

10g Spike kettle with custom 1.5" TC ferrules

--TC side pickup tube

--TC whirpool return

--TC heating element port with 240v (for lower wat density) integrated TC elelment from brewsupply

--Second TC heating element port in case I want to go all electric later using 120v and can double as probe port

March pump for recirculation

silicone tubing with camlock fittings

Voile BIAB bag

Islandboy85

Well-Known Member

Just ordered my DSPR300 and DSPR400! I'd better finish wiring up all the guts so I can hook it all up when they arrive.

this is why I love mine, never happened to me with any pid

- Joined

- Mar 24, 2016

- Messages

- 558

- Reaction score

- 60

Very curious if someone was able to determine from the instruction how one might set up the relays to trigger a pump. Process alarm? Thx.

Islandboy85

Well-Known Member

Very curious if someone was able to determine from the instruction how one might set up the relays to trigger a pump. Process alarm? Thx.

Auber said they are still working on the instruction manual for the new products. I would assume it's a very low current relay, so you may want to use it to trigger another relay at your pump that can handle higher amperage. Again, that's an assumption.

Islandboy85

Well-Known Member

Well, Auber certainly didn't waste any time there. That email I got regarding them working on a manual was from yesterday. Bravo!

this is why I love mine, never happened to me with any pid

Thanks for the input! Looks to do the trick!

Anyone else have any thoughts on using the EZ Boil with this setup! Opinions greatly appreciated!

BeardedBrews

Well-Known Member

Thanks for the input! Looks to do the trick!

Anyone else have any thoughts on using the EZ Boil with this setup! Opinions greatly appreciated!

The ez boil will work great, but if you are planning to recirculate and heat, be sure to get something to hold the bag off the element.

- Joined

- Mar 24, 2016

- Messages

- 558

- Reaction score

- 60

Any thoughts on whether or not the extra features of the dspr 300 are worth it over the dspr 120? Running pumps whole heating strike water, mashing, and chilling seem neat. Not sure about running a buzzer or extra heating elements.

the 120 has an alarm and buzzer built in, not sure whats different yet other than a hookup to an external alarm system

BeardedBrews

Well-Known Member

Any thoughts on whether or not the extra features of the dspr 300 are worth it over the dspr 120? Running pumps whole heating strike water, mashing, and chilling seem neat. Not sure about running a buzzer or extra heating elements.

If you have anything else in your system that you want to automatically turn on and off based on the programming in the DPSR, then I suppose yes.

The most obvious use is the one Auber describes, using additional elements to heat and then turning them off at boil. If you were limited to 120v this might be useful. You can also program it so that the backup element turns on if your temperature starts to drop too much.

Other options:

At 60 minutes, cut the boil and turn on the pond pump that you're using to recirculate ice water in your wort chiller.

Turn on your basement brewery's exhaust fan automatically once the wort reaches a boil.

Turn on an 8-track player with volume set to 11 playing We are the Champions as soon as your boil is finished.

Turn on an 8-track player with volume set to 11 playing We are the Champions as soon as your boil is finished.

I can get on board with this.

Islandboy85

Well-Known Member

Any thoughts on whether or not the extra features of the dspr 300 are worth it over the dspr 120? Running pumps whole heating strike water, mashing, and chilling seem neat. Not sure about running a buzzer or extra heating elements.

You have two external relay terminals. They can be used to add an additional circuit for running a relay or contractor to run additional heating elements for faster heating, a buzzer, pump, etc. they are able to be customized a little bit from what I understand. I just got my 300 and 400 in the mail he other day, but I've got family in town. I'll mess with it later next week to let you know. I think it's worth the extra couple of bucks just for the peace of mind hat (like all of us always do) you can expand your brewery bells and whistles down the road.

BeardedBrews

Well-Known Member

Turn on an 8-track player with volume set to 11 playing Hell's Bells (and Whistles) as soon as your boil is finished.

You can expand your brewery bells and whistles down the road.

[ame]https://www.youtube.com/watch?v=etAIpkdhU9Q[/ame]

So true

jeremy2027

Well-Known Member

Is there any advantage of the EZBoil compared to the 2362 PID Controller for a three vessel electric HERMS setup? They are basically the same cost and although I am not very familiar with PIDs it seems like you get more for your money with the EZBoil. Any suggestions?

in my experience with it, but I only have a few brews on it, it holds the temperature right on, no highs or lows

my pids always had a swing up and down

my pids always had a swing up and down

in my experience with it, but I only have a few brews on it, it holds the temperature right on, no highs or lows

my pids always had a swing up and down

Agreed. This thing is awesome.

jeremy2027

Well-Known Member

I'm considering just using one ezboil and a dual pole switch for the elements. I haven't quite figured out the best way to set up the rtd sensors in the hlt and boil kettle yet. I was thinking to just use xlr connections and swap them at the control panel when switching elements. Or find a way to rig them up to a switch as well.

Islandboy85

Well-Known Member

I was thinking to just use xlr connections and swap them at the control panel when switching elements. Or find a way to rig them up to a switch as well.

Use a $3 three pole double throw toggle switch for switching the RTD probes. Can you solder?

Beernip

Well-Known Member

Where are people getting their RTD sensors and XLR connectors?

Islandboy85

Well-Known Member

Where are people getting their RTD sensors and XLR connectors?

I got my temp sensors from Auber, and already had the XLR connectors from Amazon.

BeardedBrews

Well-Known Member

Where are people getting their RTD sensors and XLR connectors?

I did a ton of shopping and ended up trying two different options from Amazon to save some cash. In the end I saved very little and wish I had bought the unit from Auber. It comes with everything, including the panel mount stuff.

your not alone, don't buy the cheapest stuff you can find, buy the best and buy it once, otherwise youll have hundreds of dollars of parts laying around not being used...like me

jeremy2027

Well-Known Member

Yes I can solder, just curious if anyone has hooked RTD sensors to switch. How does it effect the sensor and will it the unit need to be calibrated everytime you flip the switch since you are using two different sensors.

the easy boil isn't as sensitive to calibration as a pid, it uses a different on and off algorithm, it pulses so fast my activity light doesn't even change, you do have to set the + or - to boiling but unless you have a temp probe way off from the other I think you'll be good

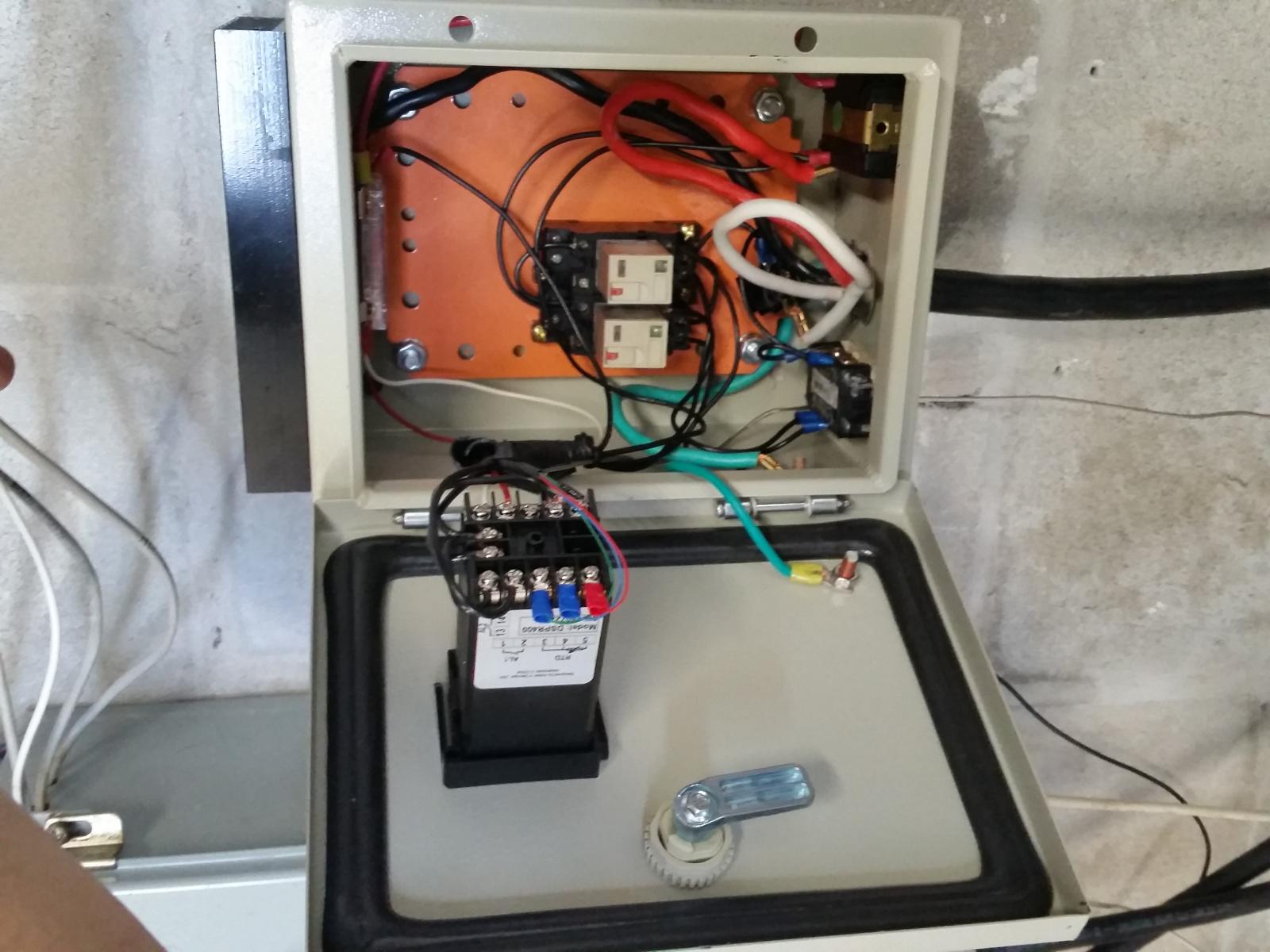

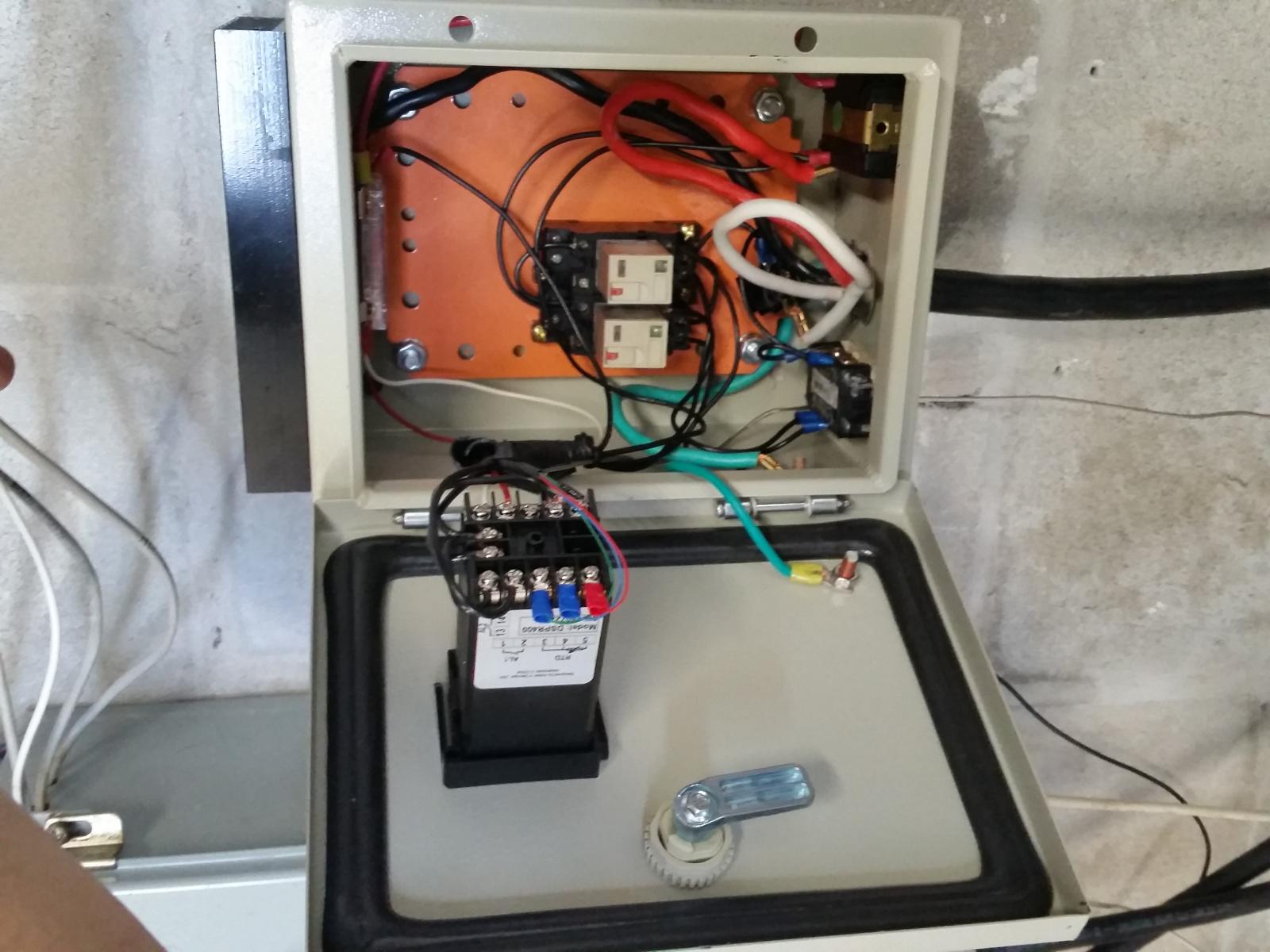

Here is my setup, DSPR400 running a 15 gallon still for making Gin. I have standard 10A 120v coil relays powered by the DSPR's internal 3A relays. need to put in some circuit breakers to keep magic smoke from escaping, but it works great...

Only using one of the relays at the moment, to turn on the cooling water pump when the vapor temp in the tube is over 160F. I have some uses for the other relay thought up, but no time...

edit - sorry about sideways pics, I always forget to to take them in landscape mode.

Here is the youtube video: [ame]https://www.youtube.com/watch?v=35LrsKcuCgU[/ame]

Only using one of the relays at the moment, to turn on the cooling water pump when the vapor temp in the tube is over 160F. I have some uses for the other relay thought up, but no time...

edit - sorry about sideways pics, I always forget to to take them in landscape mode.

Here is the youtube video: [ame]https://www.youtube.com/watch?v=35LrsKcuCgU[/ame]

So cool

gotbags-10

Well-Known Member

Will that unit do cooling? Wanting to ferment in my boil kettle. New anvil kettle with the ferment gasket. It would be nice to do all 3. Mash,boil,ferment control.

Beernip

Well-Known Member

I'm having issues getting my DSPR300 working with my SSR (uxcell® SSR-40DA-H DC-AC 40A Solid State Relay 3-32VDC/90-480VAC). I have terminal 6 connected to the negitive (4) of the ssr and 7 to the positive. The power light of the SSR fails to come on. I have 120v between SSR terminal 1 and ground but not on terminal 2. Did I get the wrong type of SSR?

Similar threads

- Replies

- 1

- Views

- 648

- Replies

- 4

- Views

- 3K

Latest posts

-

-

-

-

-

-

-

-

For Sale SS Brewtech - 7 Gallon Unitank 1.0

- Latest: IslandLizard

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)