Today I transferred beer from my conical fermenter to kegs for spunding. I transferred using 5-7 psi pressure and got a large amount of foam coming out of my keg gas post. In the past, when I spunded in the fermenter, I used a spunding valve on my keg gas post which led to foam-free transfers. I did not think I would need a spunding valve during the transfer as the beer is not carbonated yet. Obviously, there is a fair amount of carbonation present. Suggestions?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Excessive foam when transferring from fermenter to keg.

- Thread starter stevehaun

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I had struggled with the same problem. I believe that even at atmospheric pressure you might get some low carbonation. Since you have the spunding valve, just use it.

I was having troubles getting good transfers even though I tend to not carb in my conical. Once I built a spunding valve and used it on the gas out post of my keg my problems seem to have gone away. (Knock on wood) In this case I'm willing to forgo the explanation and just accept that it works!

I was having troubles getting good transfers even though I tend to not carb in my conical. Once I built a spunding valve and used it on the gas out post of my keg my problems seem to have gone away. (Knock on wood) In this case I'm willing to forgo the explanation and just accept that it works!

I was wondering if I simply used too much pressure? Perhaps if I pushed the beer with 2-3 psi there would be less foam? Today I started with 7 psi and turned it down to 5 psi when I started getting foam. That change did not seem to make a difference.

The temperature of your keg can make a difference too. If you are cold crashing in the fermenter and then putting it in a warm keg you would get some foaming. Same for lines, fittings, etc. Although those would probably chill after the first few pints went through them.

2-3 PSI to push might help. But you know what will really help? Use your spunding valve.

2-3 PSI to push might help. But you know what will really help? Use your spunding valve.

Having just filled four kegs from crashed carboys - and from years of experience - I doubt it's the keg temperature per se. There's not a lot of thermal mass in a corny keg that the beer actually contacts.

But...if the fermentor was sealed and governed by a blow-off valve it's probably more carbonated than what comes out of my carboys, and that tends to amplify issues (like racking pressure, and maybe temperature). Bubbles beget bubbles during transfers, so if the transfer pressure isn't high enough to keep the dissolved CO2 in solution it's going to break out and in turn cause some cascade effects.

So...as already stated, using a spunding valve on the receiving keg should allow the use of enough pressure during racking to keep dissolved CO2 in solution...

Cheers!

But...if the fermentor was sealed and governed by a blow-off valve it's probably more carbonated than what comes out of my carboys, and that tends to amplify issues (like racking pressure, and maybe temperature). Bubbles beget bubbles during transfers, so if the transfer pressure isn't high enough to keep the dissolved CO2 in solution it's going to break out and in turn cause some cascade effects.

So...as already stated, using a spunding valve on the receiving keg should allow the use of enough pressure during racking to keep dissolved CO2 in solution...

Cheers!

- Joined

- May 28, 2018

- Messages

- 3,262

- Reaction score

- 2,971

I transfer from conical to spund in kegs also, have not needed to use spunding valve on gas post, just a line off it in case there is a little foam near when keg reaches capacity. Usually I only use 2 or 3 PSI CO2 to push transfer.

I do recall getting foam a couple times when I transferred when SG was a little higher than usual, as I did not want to miss "spunding window" during busy time at work, (maybe I should have used spunding valve for that).

In general, I do not get foam when transferring withing .006-.010 away from finish gravity, when airlock activity has significantly slowed..

I do recall getting foam a couple times when I transferred when SG was a little higher than usual, as I did not want to miss "spunding window" during busy time at work, (maybe I should have used spunding valve for that).

In general, I do not get foam when transferring withing .006-.010 away from finish gravity, when airlock activity has significantly slowed..

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$11.99

DERNORD 1/2 Inch Stainless Steel Quick Disconnect Set - Beer Brewing Connector Kit (Barb Female/FPT Male)

denuodianqiyouxiangongsi

$19.99

$22.99

How To Brew: Everything You Need to Know to Brew Great Beer Every Time

Simon & Schuster Digital Sales LLC

Robert65

Major Obvious (recently promoted)

I transfer to keg to spund using no more than 5-6 psi. My method is to put a picnic tap on the gas post of the purged and initially pressurized receiver keg (fermenter and keg at equal pressure.) I periodically vent some pressure to keep flow moving. This will suppress foaming just as in a true counterpressure transfer, and will prevent overflow if you step away or at the end. That said, like the previous post notes, I don't have any such problem transferring within a fairly broad interpretation of the "window," when activity has subsided a bit.

So basically the picnic tap serves as a spunding valve whereas I was venting my keg into a bucket of sanitizer.

Cavpilot2000

Well-Known Member

I'd vote for too much pressure. I transfer at 1-2 PSI (from a SS Brewbucket).

Robert65

Major Obvious (recently promoted)

Yep. Not a precise spunding valve (actually I got the idea from the purge valve on a CP bottle filler,) and unlike a spunding valve, I don't care if beer or foam does get in it. In fact I let beer come out the gas post, then dispense a known amount for a known headspace in the keg.So basically the picnic tap serves as a spunding valve whereas I was venting my keg into a bucket of sanitizer.

Yep. Not a precise spunding valve (actually I got the idea from the purge valve on a CP bottle filler,) and unlike a spunding valve, I don't care if beer or foam does get in it. In fact I let beer come out the gas post, then dispense a known amount for a known headspace in the keg.

OMG, I can't believe I never thought of letting the keg fill to the gas out post and THEN dumping a few pints. This is brilliant!

Robert65

Major Obvious (recently promoted)

And you get to drink some slop while kegging. Only works if you can brew enough and send enough to the fermenter to account for losses. But it does make life less anal.OMG, I can't believe I never thought of letting the keg fill to the gas out post and THEN dumping a few pints. This is brilliant!

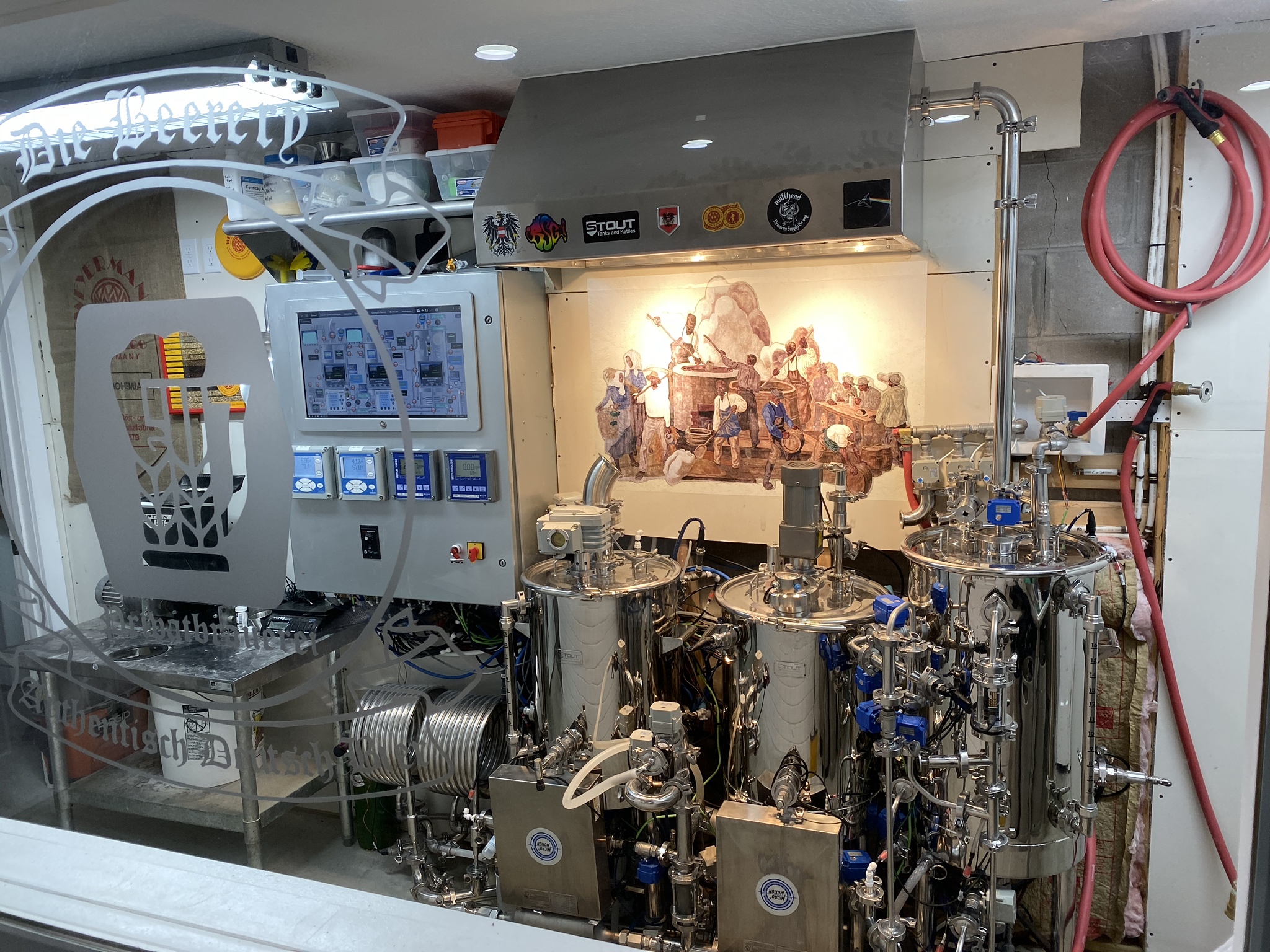

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 643

OMG, I can't believe I never thought of letting the keg fill to the gas out post and THEN dumping a few pints. This is brilliant!

Uhh yea. Stupid simple. All these people with scales make me laugh.

Yep. Not a precise spunding valve (actually I got the idea from the purge valve on a CP bottle filler,) and unlike a spunding valve, I don't care if beer or foam does get in it. In fact I let beer come out the gas post, then dispense a known amount for a known headspace in the keg.

If you were overvolume enough that you wanted to bottle off the excess, I imagine you could either use a bottling wand shoved into the picnic tap or just use the normal run of tubing into the bottom of a bottle and be on your merry way?

Uhh yea. Stupid simple. All these people with scales make me laugh.

Cheers! (That's a metric crapton of irony right there

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 643

Yea I spose.

Similar threads

- Replies

- 25

- Views

- 740

- Replies

- 2

- Views

- 303

- Replies

- 3

- Views

- 401