Oatmeal Stout, mashed way to high (160s).

OG=1.063. FG = 1.032. Ouch. This after 2 weeks fermentation.

I pulled a test jar and added amylase enzymes. 1/4 tsp. Test jar sat at room temp. Here's how that turned out:

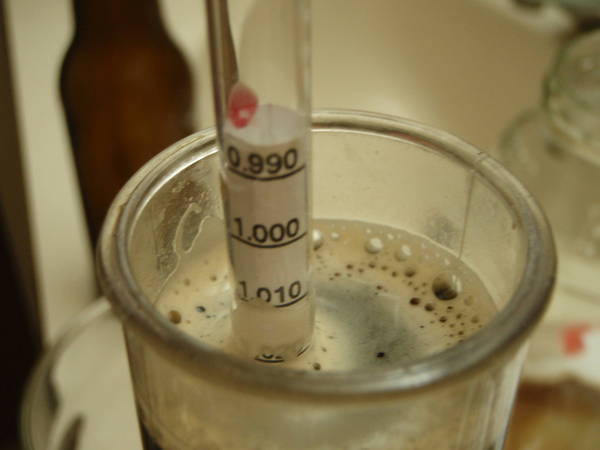

December 11, before enzymes:

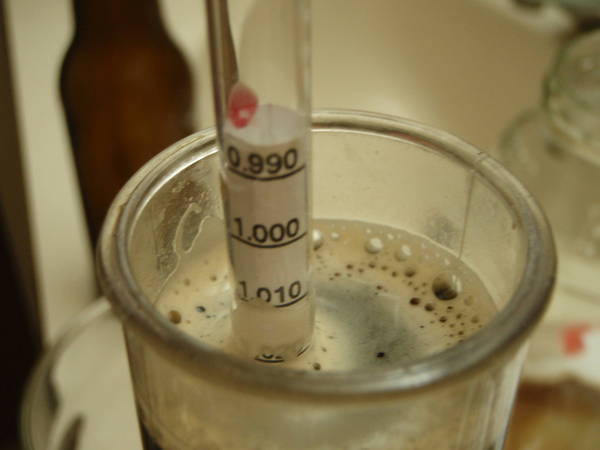

December 13, 2 days after enzymes added

December 18, 7 days after enzymes added; pen added to increase volume of test jar so hydrometer would float

Today (December 20), the gravity is still 1.012.

OG=1.063. FG = 1.032. Ouch. This after 2 weeks fermentation.

I pulled a test jar and added amylase enzymes. 1/4 tsp. Test jar sat at room temp. Here's how that turned out:

December 11, before enzymes:

December 13, 2 days after enzymes added

December 18, 7 days after enzymes added; pen added to increase volume of test jar so hydrometer would float

Today (December 20), the gravity is still 1.012.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)