Brewer dad

Well-Known Member

I am looking to upgrade from stovetop/cooler batch sparge setup to an electric full volume biab recirculating system. My short term goals for this system are to eliminate moving wort during mash process, reduce brew day time, and gain the ability to more easily execute mash schedules. I do primarily 5 gallon batches but wouldn’t mind the ability to occasionally do 10 gallon sub 1.050 batches. To reduce costs/enjoy learning I am looking to put this system together myself.

I have some questions related to hardware that I’m not seeing previously asked so I figured I’d start a new thread in the hopes it helps someone in the future. I am loosely modeling this system after brew hardware’s premium build, and plan to obtain many components from them.

Kettle will be spike, either 15-20 gallon.

-leaning towards 15 gal, any idea how much head space is beyond the 15 gal mark? Running 10 gal numbers and for total volume sometimes looking right around 15-15.5 gal for batches I’d want

-where are y’all putting thermometers?

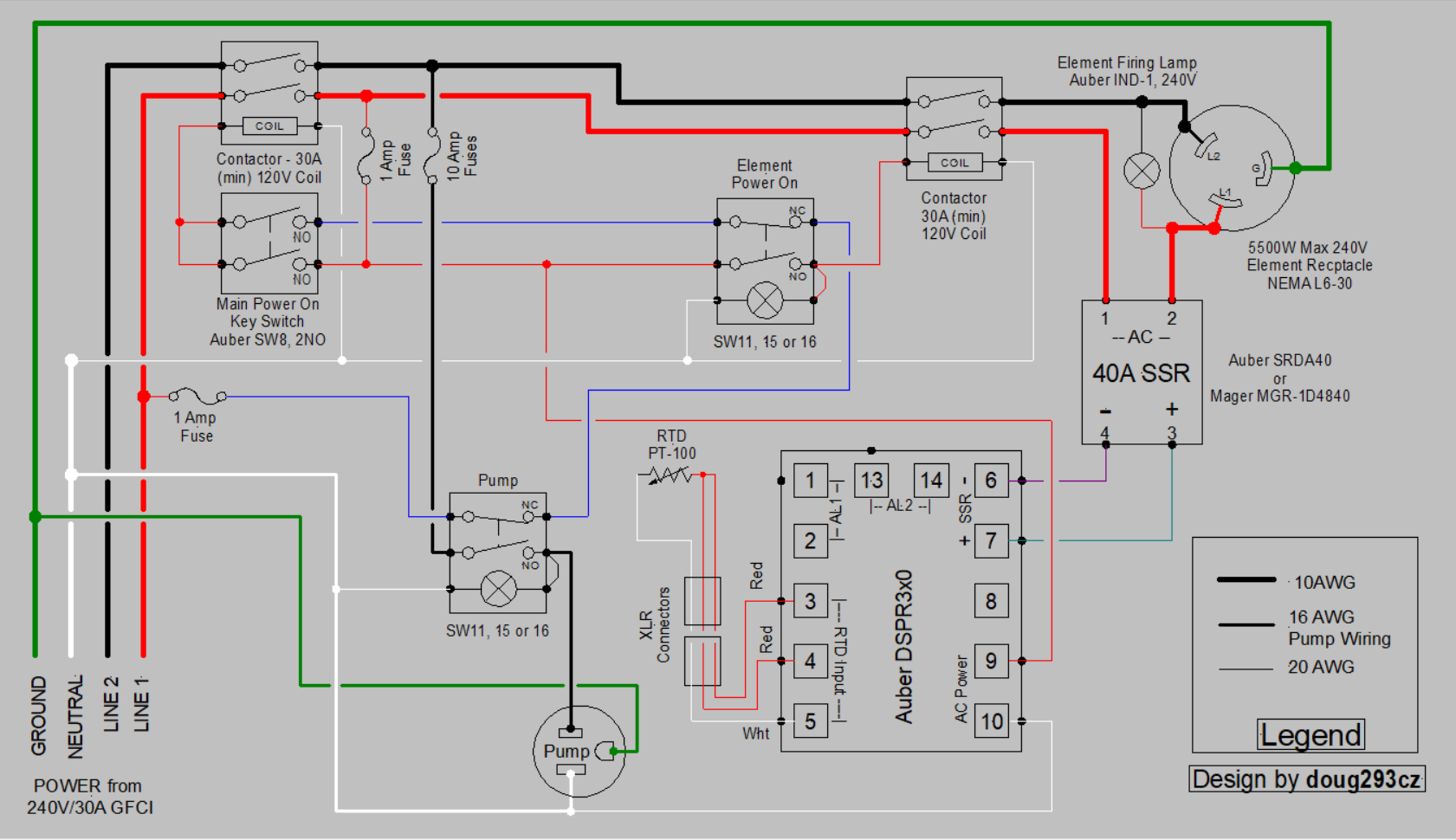

Controller will be auber components that I put together. 240v 5500w pid setup.

-I am thinking of not bothering with a plug on the controller for the pump, I have plenty of outlets around and would simplify the setup, any reason this is a bad idea so long as my pump is otherwise well setup?

-for PIDs I’m looking at either ez boil or the ramp/soak with wifi(AW-SYL-23X2P). I see what seems to be good stuff about ez boil but the ramp soak seems similar and I can manipulate it from my phone. Anyone have experience with the ramp/soak?

Thanks in advance for any input. When I am further along in the process I will post a diagram and then final product.

I have some questions related to hardware that I’m not seeing previously asked so I figured I’d start a new thread in the hopes it helps someone in the future. I am loosely modeling this system after brew hardware’s premium build, and plan to obtain many components from them.

Kettle will be spike, either 15-20 gallon.

-leaning towards 15 gal, any idea how much head space is beyond the 15 gal mark? Running 10 gal numbers and for total volume sometimes looking right around 15-15.5 gal for batches I’d want

-where are y’all putting thermometers?

Controller will be auber components that I put together. 240v 5500w pid setup.

-I am thinking of not bothering with a plug on the controller for the pump, I have plenty of outlets around and would simplify the setup, any reason this is a bad idea so long as my pump is otherwise well setup?

-for PIDs I’m looking at either ez boil or the ramp/soak with wifi(AW-SYL-23X2P). I see what seems to be good stuff about ez boil but the ramp soak seems similar and I can manipulate it from my phone. Anyone have experience with the ramp/soak?

Thanks in advance for any input. When I am further along in the process I will post a diagram and then final product.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)