cyberbackpacker

Well-Known Member

kevin9167, so basically the receptacle is a mechanical switch, which then negates the need for the SSR? And yes, it would make sense that for pumps, heaters, etc. that a mechanical switch should suffice due to longer duty cycles.

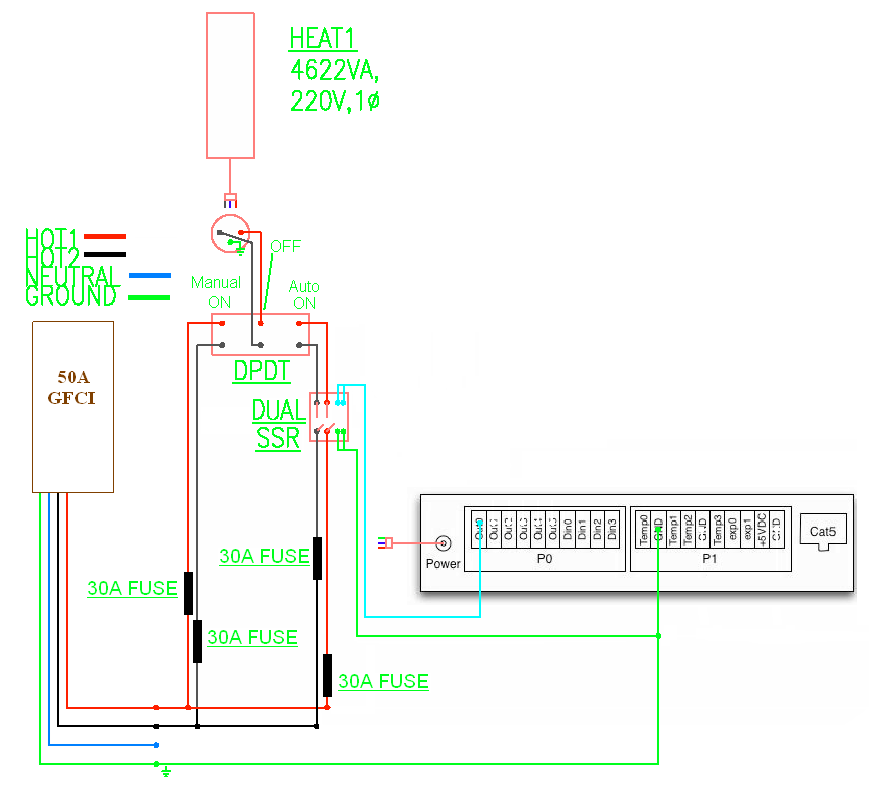

As for the 40a SSR on the elements, what I was proposing was to exchange my 25a SSR's since I will be using a mechanical relay instead (the receptacles). I would exchange the 25a SSR's for three 40a SSR's. Then run two 40a SSR's for each element... in essence a "dual" ssr.

Savvy?

As for the 40a SSR on the elements, what I was proposing was to exchange my 25a SSR's since I will be using a mechanical relay instead (the receptacles). I would exchange the 25a SSR's for three 40a SSR's. Then run two 40a SSR's for each element... in essence a "dual" ssr.

Savvy?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)