Thank you for the information. I want convenience + the possibility for other system changes in the future, and picked up a PID with manual mode fairly cheap.

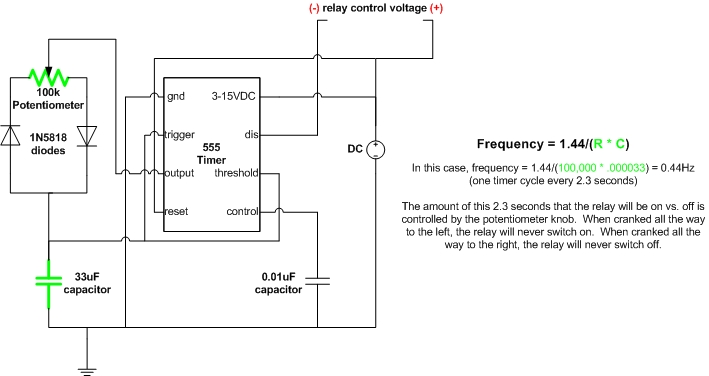

That said, I would love to see a diagram of the simple pulse width modulator.

As I mentioned, this is the first step of a much bigger project for me. My induction heat-on-demand unit is actually going to be coded through an arduino I already have, to adjust flow rate of the incoming water, electric pulse, and wattage, in order to hhave the water exiting be at a temperature that I dial in.

I may as well hijack my own thread at this point, but I am working toward the following setup:

1) Electric Kettle

2) Reservoir / Mash Tun

3) IHWOD (Induction Hot-Water-On-Demand) hose unit

My brew process would be as follows:

Put grains in Mash Tun, use IHWOD to put water in at a preset temperature. Mash. Use IHWOD in place of an HLT for additional water. Pump into Kettle. Boil. Done.

The kettle I have at the moment is a cheap one that I plan to eventually replace. Therefore, I am putting together the equipment and systems I want, as I can get them together (time + beer allowance). My last purchases in this plan will also be the most expensive. First will be a nice, big metal container for my mash tun. Second will be a nice, big new kettle. Third will be a conical fermenter.

Once I am into the conical, I will start on my ideas for refrigeration instead.

And, to quote SWMBO: "He never does anything the easy way, but he sure has fun doing it."

But, at this stage, I'm just trying to boil me some beer, because my new home doesn't have existing facilities that make it easy for me to brew, and I want to go electric. And some evil part of me thinks that this all, somehow, makes sense. I'm not entirely convinced that part of me is right, but hell, I'll have fun tryin'!

- M

PS: I tried to find an infinite switch for this, never found one.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)