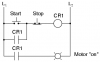

That relay circuit is so wrong! It would take several paragraphs to explain what is wrong and how to fix it. When "Start" is pressed, the voltage at pins 6 & 8 goes to zero, since the relay coil will drop the full 120V across it. Then there is no voltage going to the main power bus. And as pointed out there is no latching function. I suggest you go back to the Electric Brewery site and study the safe start circuit until you understand it.

Brew on

Brew on

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)