So I am planning to make the jump to electric brewing. I am converting a 16 gallon kettle to use a 5500w 240v element and use it as m HLT. (Counterflow HERMS) The boil kettle will have the same element. I am buying the High Gravity EBC-SV system. My question: Can I use the PID controller to control both elements (not at the same time) by feeding a box with two double pole switches (like these http://www.homedepot.com/p/Leviton-...ble-Pole-Switch-White-R62-03032-2WS/100356941) and simply only turn one switch on at a time? I know I can simply swap out the cables to each element with a twistlock but this would allow me to hardwire the elements to the switches and the switches to the controller. Any concerns? How do I make the connections in the box, big wire nuts? Will a normal deep switch box be fine? Should I use a small subpanel box?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Electric Controller Double Duty

- Thread starter bzevotek

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

jeffmeh

Well-Known Member

- Joined

- Feb 26, 2009

- Messages

- 2,145

- Reaction score

- 216

Unless you have a 50a circuit, you really should not wire it such that both elements can run at the same time. If you were building your own controller, the proper way to do it would be with a 3-position switch (HLT-Off-BK) driving two separate contactors. You could certainly build a separate box with this configuration that is fed by the High Gravity EBC-SV, but if you have the skills to do that you may want to do the whole panel DIY.

Jeffmeh's approach is correct because you cannot accidentally turn both elements on at the same time. Personally, I would simply unplug one and plug in the other. So simple. I have a 50 amp system with two 4500 watt elements in both the boil kettle and HLT. When I am done with the mash, I unplug the HLT elements and plug in BK elements. Hard to beat cheaper and simpler.

So I bought this switch. http://www.globalindustrial.com/p/e...ouble-Pole-Double-Throw-30A-120-277V-AC-Brown

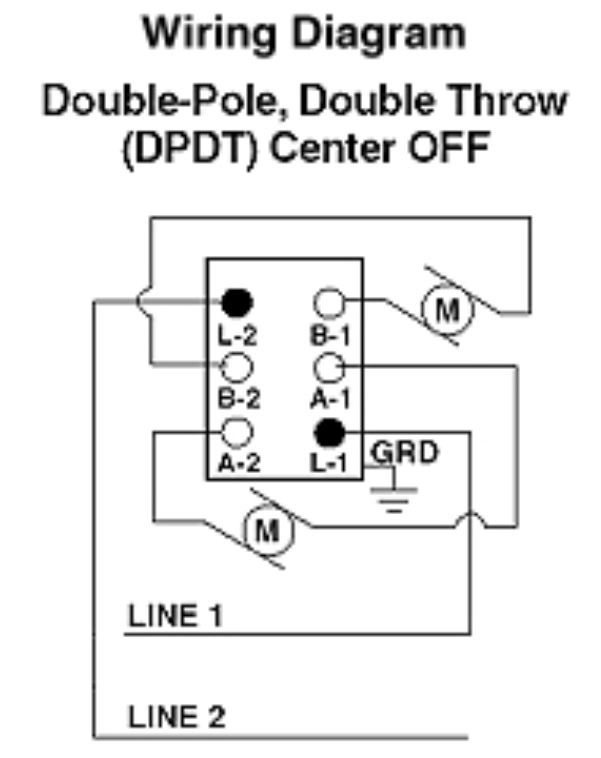

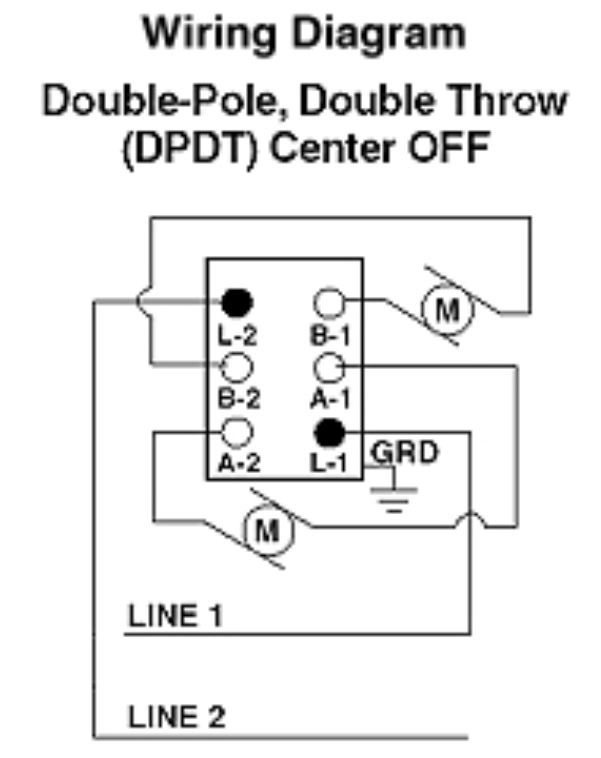

If I understand the diagram right the black screws are hot, then "like" colors feed each element. Planning to do a continuity test when it arrives by running a jumper between my hots and then flipping the switch through all three positions to verify before wiring it in. Shortly after posting this I found this switch and realized for a few extra bucks I can eliminate the possibility of both being powered at once with a 3 position switch.

Hoping that with just one controller and an extra sensor all I will have to do is swap the sensor leads, turn on the pump and flip the switch to the other element. Am I tracking correctly on this? Thanks again guys.

If I understand the diagram right the black screws are hot, then "like" colors feed each element. Planning to do a continuity test when it arrives by running a jumper between my hots and then flipping the switch through all three positions to verify before wiring it in. Shortly after posting this I found this switch and realized for a few extra bucks I can eliminate the possibility of both being powered at once with a 3 position switch.

Hoping that with just one controller and an extra sensor all I will have to do is swap the sensor leads, turn on the pump and flip the switch to the other element. Am I tracking correctly on this? Thanks again guys.

Similar threads

- Replies

- 8

- Views

- 601

- Replies

- 11

- Views

- 969

- Replies

- 0

- Views

- 721