OK, so I've ordered several parts, and some have even come in already. There are a few things I'm unsure of, though, which I'll need some help with.

Here are some more details:

- I'm planning to use DIN mount breakers.

- I'm open to DIN mount terminal blocks, but I've seen the standard chassis mount ones for much cheaper. Jury's still out on this one.

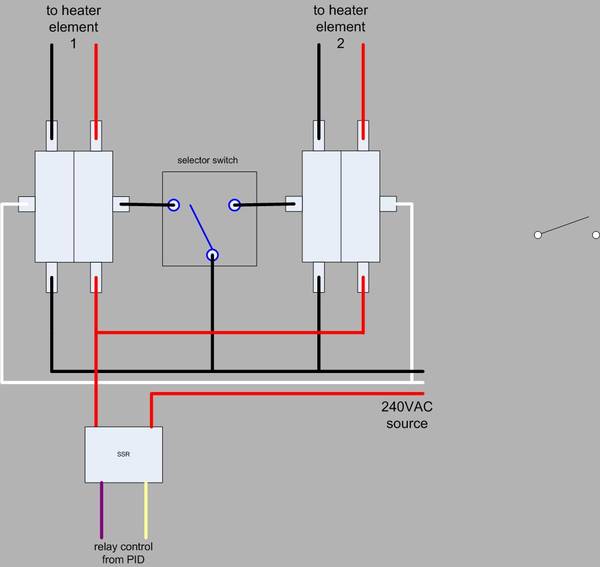

- I'm planning on using the wiring diagram provided by P-J here.

Now the questions:

1. I'm not sure what kind of terminal blocks to get, and where to get them. I've looked on

www.digikey.com and

www.automation.com, among others, but there are several choices and I want to make sure I don't have to order anything more than once, or worse yet, put the wrong thing in my CP and fry something (or someone).

2. Also, the same for the breakers. What kind? Where? Safety first.

3. What kind of fuses and fuse mounts to get, and where?

4. What's the best way to cut the square holes in the enclosure panel for the PIDs? I've got a 22.5 mm knock out punch for the switches, but the square knock outs go for around $400. Is it time to invest in a Dremel? What methods have you heard/seen/done?

5. I noticed the wiring diagram doesn't have a master power switch. If I were to use one, again - how to select the right one and where to buy?

P-J, Would I wire that with L1 and L2 right after the terminal blocks?

6. Also, I'm thinking of using a 4500W element in the HLT now instead of the 5500W. Any changes to the schematic? Any parts changes besides the element of course?

Thanks again,

TB

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)

You could try a proxy. If they block one of them, simply switch to another. I used to do this all the time at my last job

You could try a proxy. If they block one of them, simply switch to another. I used to do this all the time at my last job