You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

E keggle build

- Thread starter emyers

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

ITS ALIVEEEE!!!!!

I tested it out with 3 gals in each, switches between elements perfectly. The box worked but its real tight in there especially with the large computer power supply. It will work but its real tight especially with my rats nest wiring. This should hold me over until i have additional funds to go automated and get a proper large box.

Brew tomorrow with a 33 lbs grain bill . I'll have to lift the wort up to the boil kettle since i have no pump, the drop is not enough for my tiny CFC. I badly need to upgrade to a CFC with a 1/2 copper coil.

. I'll have to lift the wort up to the boil kettle since i have no pump, the drop is not enough for my tiny CFC. I badly need to upgrade to a CFC with a 1/2 copper coil.

my 2' 3/8" SS rod came in today.. well it was supposed to.. instead i got an empty box with a 3/8 hole in the bottom. Luckily its amazon so ill have it replaced no problem. This will be the stir rod for my HLT. Ill be making a SS prop with the keg cutouts.

I tested it out with 3 gals in each, switches between elements perfectly. The box worked but its real tight in there especially with the large computer power supply. It will work but its real tight especially with my rats nest wiring. This should hold me over until i have additional funds to go automated and get a proper large box.

Brew tomorrow with a 33 lbs grain bill

my 2' 3/8" SS rod came in today.. well it was supposed to.. instead i got an empty box with a 3/8 hole in the bottom. Luckily its amazon so ill have it replaced no problem. This will be the stir rod for my HLT. Ill be making a SS prop with the keg cutouts.

anyone know why the master switch wont work? It turns the system on but wont light up. I have one of the legs that supplies the power supply running 240v hooked up to it. That should be pushing 120v thru it no?

I realize now what is needed to light up the switch. I need to wire it like in the third pic on this item description,

http://www.ebrewsupply.com/indicators-switches/push-buttons/blue-led-push-button.html

Sadly i was not able to brew. I will have to hold off till monday. On the up side my float switches came in from china so i can wire in the element protection circuit before then.

On the up side my float switches came in from china so i can wire in the element protection circuit before then.

http://www.ebrewsupply.com/indicators-switches/push-buttons/blue-led-push-button.html

Sadly i was not able to brew. I will have to hold off till monday.

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$159.99 ($26.66 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

SpaceCityProviders

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

Finally got to brewing yesterday. My manual mash recirc sucked dumping three gals into a 3000w turkey fry pot to adjust temp.

I ran into an issue. My 5500w SSRs stay on when turned off. Its only after they have been on for a bit. Any ideas why this is happening?

I ran into an issue. My 5500w SSRs stay on when turned off. Its only after they have been on for a bit. Any ideas why this is happening?

I got my hands on a nice big waterproof box to upgrade to. This should be big enough to run everything i would ever dream to expand to. Its 24"x 18" and like 10" deep. It has a few holes but i can easily make use of them, nothing excessive. Best of all it has some hardware i can use. I'm not sure what the control box is for, but im sure its not a brew controller.

BTW i still have not figured out why the SSRs that control the 5500w elements stay when they have been on for a while. The 3500w are wired the same exact way and dont have an issue.The SSR's are rated at 40A so its not like im over powering it either. I can swap between the two as designed when only doing so for a few seconds. Once the elements have been on for a min or two it seems to freeze the SSR in the on position and allows me to turn on two 5500w elements at the same time.... on the same 30A leg :O Does anyone have any recommendations to help?

BTW i still have not figured out why the SSRs that control the 5500w elements stay when they have been on for a while. The 3500w are wired the same exact way and dont have an issue.The SSR's are rated at 40A so its not like im over powering it either. I can swap between the two as designed when only doing so for a few seconds. Once the elements have been on for a min or two it seems to freeze the SSR in the on position and allows me to turn on two 5500w elements at the same time.... on the same 30A leg :O Does anyone have any recommendations to help?

jeffmeh

Well-Known Member

- Joined

- Feb 26, 2009

- Messages

- 2,145

- Reaction score

- 216

BTW i still have not figured out why the SSRs that control the 5500w elements stay when they have been on for a while. The 3500w are wired the same exact way and dont have an issue.The SSR's are rated at 40A so its not like im over powering it either. I can swap between the two as designed when only doing so for a few seconds. Once the elements have been on for a min or two it seems to freeze the SSR in the on position and allows me to turn on two 5500w elements at the same time.... on the same 30A leg :O Does anyone have any recommendations to help?

When one of the SSRs is locked "on," have you checked the control voltage from the PID to the SSR? If the PID is sending the voltage signal, then there is something wrong on the PID side. If not, then it's on the SSR side. It could be PID settings, a bad PID, a bad SSR, or improper wiring.

Update, Still not done building this rig but its operational. My funds got diverted to racing for the season. Plans are still to upgrade to the larger enclosure, install HERMS, and go automated.

Still having issues with sticking SSR's. Dam sure its because there cheap made in china knockoffs. Its only once they warm up a bit. The relays came with heat sinks and im going to put thermal pase on the mounting point and see if that helps. I checked yesterday and verified that the SSR control side does turn off when its stuck on. Even the LED indicator turns off.

I actually melted down a SSR last brew. I replaced it with one off the 3500w circuit and still no bueno.

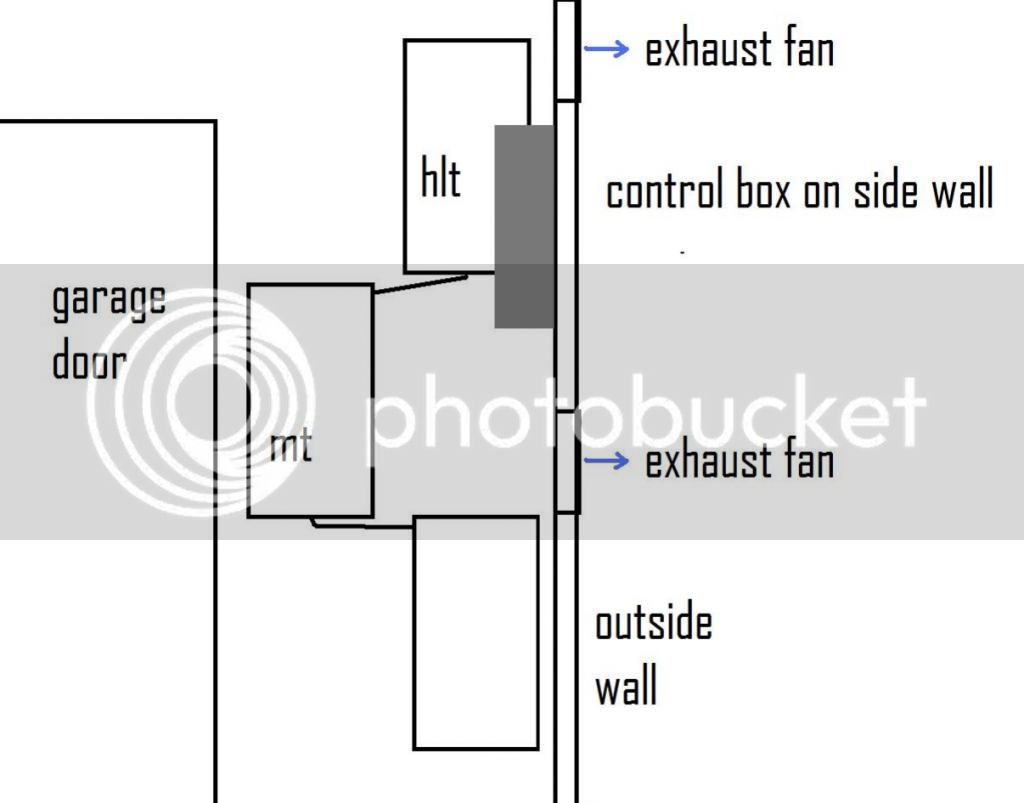

I wish i had a taller celing in my garage so i could have everything gravity fed. Right now i need to pump from my mash tun to boil kettle but besides that everything is automated.

So far permantly mounting the kettle and HLT seems to work fine. The HLT gets drained and the boil kettle gets cleand up in place using the bottom drain. I currently remove the mash tun but plan to install a dump mechanisim.

Hopefully this fall i can swap over to the larger enclosure and solve this sticky relay issue. I also still need to install all my safety float switches and start the automation.

Still having issues with sticking SSR's. Dam sure its because there cheap made in china knockoffs. Its only once they warm up a bit. The relays came with heat sinks and im going to put thermal pase on the mounting point and see if that helps. I checked yesterday and verified that the SSR control side does turn off when its stuck on. Even the LED indicator turns off.

I actually melted down a SSR last brew. I replaced it with one off the 3500w circuit and still no bueno.

I wish i had a taller celing in my garage so i could have everything gravity fed. Right now i need to pump from my mash tun to boil kettle but besides that everything is automated.

So far permantly mounting the kettle and HLT seems to work fine. The HLT gets drained and the boil kettle gets cleand up in place using the bottom drain. I currently remove the mash tun but plan to install a dump mechanisim.

Hopefully this fall i can swap over to the larger enclosure and solve this sticky relay issue. I also still need to install all my safety float switches and start the automation.

Well i now know its not my own fault the SSR's are sticking. Seems these 40A models off amazon are junk. 1/2 of the reviews claim the same issue when putting a 20+ amp load on it at 100%.

http://www.amazon.com/Amico-Single-...dp_top_cm_cr_acr_txt?ie=UTF8&showViewpoints=1

http://www.amazon.com/Amico-Single-...dp_top_cm_cr_acr_txt?ie=UTF8&showViewpoints=1

Race season is over so now its back to brewing. I think i found what valves i will be using,

https://www.oscsys.com/store/valves

The 3 way valve would be tits for recirculation then switching to fill the BK.

I really need to get started on the recirc so one of the first things on my list is a 25' x 1/2" SS for the HERMS coil and some fittings.

https://www.oscsys.com/store/valves

The 3 way valve would be tits for recirculation then switching to fill the BK.

I really need to get started on the recirc so one of the first things on my list is a 25' x 1/2" SS for the HERMS coil and some fittings.

I rounded up all the parts for herms. I made a batch of oatmeal honey porter today and HERMS worked great. I really need input/output probes on the mash tun. Lesson learned don't bend a herms tube after half a bottle of vodka. I kinked the tube in a few spots. Wasted or not bending SS tube is no easy task. Next time i will just find a supplier who can custom bend to a 12" OD spiral. The good thing is i never have to look at the coils.

I wired in the new 40A relays previously and they work great, no sticking!

I went and bought a 2nd chugger pump for the HERMS. Thats now mounted off my tri clover fitting with a 3 way valve off the end of it. I was thinking i could swap from HERMS to filling the boil kettle with ease. Now i realize i can't regulate flow out the pump. When i try to slow the flow it redirects the flow out the other port. This is causing the wort to recirculate too fast. I was able to bandaid it today with about 1.5lb rice hulls and a tight zip tie on the pump output to HERMS. So i may be buying two regular valves to replace the 3 way.

I mig welded the fittings for the herms. I think i got it down, keep the stick out real short, like 1/8" to get the weld started then keep it around 1/4" I kept getting horrible sputtering and no penetration on start if i had any more stick out than 1/4". I welded with tri mix on the welder and argon co2 back purge with a cracked open tank hooked to some 1/2" silicone tube. It worked well from what i can tell. Came out much better than my first welded keggle. I made sure to only weld 1/2" at a time so the bung didn't get distorted.

Hopefully i can finish mounting the kegs and get the boil kettle mounted as well. Having it resting on the random 2x4s and 4x4 is sketchy. So far the wall mounts are working great. I hope to install a dump bracket soon for the mash tun but for now my removable slotted holes work well. Cleaning the BK in place is no problem at all either. I plan to wall mount the BK below the mash tun, so i wont even need a step stool to clean it.

I wired in the new 40A relays previously and they work great, no sticking!

I went and bought a 2nd chugger pump for the HERMS. Thats now mounted off my tri clover fitting with a 3 way valve off the end of it. I was thinking i could swap from HERMS to filling the boil kettle with ease. Now i realize i can't regulate flow out the pump. When i try to slow the flow it redirects the flow out the other port. This is causing the wort to recirculate too fast. I was able to bandaid it today with about 1.5lb rice hulls and a tight zip tie on the pump output to HERMS. So i may be buying two regular valves to replace the 3 way.

I mig welded the fittings for the herms. I think i got it down, keep the stick out real short, like 1/8" to get the weld started then keep it around 1/4" I kept getting horrible sputtering and no penetration on start if i had any more stick out than 1/4". I welded with tri mix on the welder and argon co2 back purge with a cracked open tank hooked to some 1/2" silicone tube. It worked well from what i can tell. Came out much better than my first welded keggle. I made sure to only weld 1/2" at a time so the bung didn't get distorted.

Hopefully i can finish mounting the kegs and get the boil kettle mounted as well. Having it resting on the random 2x4s and 4x4 is sketchy. So far the wall mounts are working great. I hope to install a dump bracket soon for the mash tun but for now my removable slotted holes work well. Cleaning the BK in place is no problem at all either. I plan to wall mount the BK below the mash tun, so i wont even need a step stool to clean it.

Looks like a lot of challenges to overcome with this build. Good on you for sticking with it.

Well i now know its not my own fault the SSR's are sticking. Seems these 40A models off amazon are junk. 1/2 of the reviews claim the same issue when putting a 20+ amp load on it at 100%.

http://www.amazon.com/Amico-Single-...dp_top_cm_cr_acr_txt?ie=UTF8&showViewpoints=1

Looks to me like another one selling stuff he don't understand. The heat sink shown in the picture is under sized for 40 Amps unless you use forced air cooling. Even 20 Amps would make the heat sink very hot without cooling.

I have real bad luck with SSR's It seems after the amazon junk Amico SSR's I was sent a DOA SSR from Electric brewery. Luckily they sent me a new SSR for free and thats working perfectly now.

I finally mounted the boil kettle and it works great where its at. Real easy to monitor. Then when im done i just pump it up and out the CFC. The last half gallon or so i top off the kettle with fresh water to flush out all the wort in the pump, hoses, and CFC into the fermenter.

I removed the three way valve off the MT and installed a X fitting with a thermometer, Herms pump, and bottom valve that drains to the BK. Not really loving how my pump is hanging off the MT, i really need to wall mount it but i ran out of silicone hose.

I finally mounted the boil kettle and it works great where its at. Real easy to monitor. Then when im done i just pump it up and out the CFC. The last half gallon or so i top off the kettle with fresh water to flush out all the wort in the pump, hoses, and CFC into the fermenter.

I removed the three way valve off the MT and installed a X fitting with a thermometer, Herms pump, and bottom valve that drains to the BK. Not really loving how my pump is hanging off the MT, i really need to wall mount it but i ran out of silicone hose.

Purchased an amazon mypin PID for the HLT. The up function button was non op on arrival. I returned it and ordered an auber SSR PID. Don't waste time with the cheap amazon PID's the instructions go as far as wiring and good luck from there. Amazon electronics sure have given me a dam headache on this build, faulty SSRS and now this.

I had to take apart my BK>chiller chugger pump the other day. There was a buildup of ferrous particles between the magnetic drive and inside of the ss plate that goes over it, they were stuck to the drive magnet in strips. The pump was not starting up without turning it on and off a bunch of times. I put a light coating of food grade silicone on the pump shaft to help lube that too. Seems to work fine now.

I had to take apart my BK>chiller chugger pump the other day. There was a buildup of ferrous particles between the magnetic drive and inside of the ss plate that goes over it, they were stuck to the drive magnet in strips. The pump was not starting up without turning it on and off a bunch of times. I put a light coating of food grade silicone on the pump shaft to help lube that too. Seems to work fine now.

Slight change of plans. I realized after the fact that i mounted my elements on the wrong side of the kegs. The wires not only hang over the MT but they have to loop around both BK and HLT. However this seems to work to my benefit. I plan to move everything to the corner in my garage 6 feet left and on the opposite side of the breaker box and outlets. This should not only fix my wiring issue but also save space for my other hobbies and only dirty the corner right near the garage door.. aka my clean up drain. I also plan to install a sheet or two of FRP (plastic panels) from home depot to waterproof the corner.

On the backburner is plans to use two 55 gal rain barrels i have as cooling water. Inspired by a method i saw on moonshiners by the industrial still. Crap show but every once in a while there is some jem info. A cheap high vol sump pump and plumbing attaching the two drums should do it.

On the backburner is plans to use two 55 gal rain barrels i have as cooling water. Inspired by a method i saw on moonshiners by the industrial still. Crap show but every once in a while there is some jem info. A cheap high vol sump pump and plumbing attaching the two drums should do it.

augiedoggy

Well-Known Member

Why the two elements vs just using the 5500w element with a $25 manual mode capable pid? I've have great success controlling and dialing the boil right in where I want it.

Guess I just got lucky with all three of my "cheap" pids and ssrs..... no issues so far. And I have one 25 and one 40 amp one.. with heat sinks and thermal grease though.

Very strange yours overheated when you weren't even: using them as intended.... they are designed to be able to switch on and off really fast by a pid which wold make them run hotter than just on 100% controlled by a knob unless I'm missing something? It does see like something else could be the culprit.

Guess I just got lucky with all three of my "cheap" pids and ssrs..... no issues so far. And I have one 25 and one 40 amp one.. with heat sinks and thermal grease though.

Very strange yours overheated when you weren't even: using them as intended.... they are designed to be able to switch on and off really fast by a pid which wold make them run hotter than just on 100% controlled by a knob unless I'm missing something? It does see like something else could be the culprit.

Why the two elements vs just using the 5500w element with a $25 manual mode capable pid? I've have great success controlling and dialing the boil right in where I want it.

Guess I just got lucky with all three of my "cheap" pids and ssrs..... no issues so far. And I have one 25 and one 40 amp one.. with heat sinks and thermal grease though.

Very strange yours overheated when you weren't even: using them as intended.... they are designed to be able to switch on and off really fast by a pid which wold make them run hotter than just on 100% controlled by a knob unless I'm missing something? It does see like something else could be the culprit.

Because 9000W>5500W faster ramping. I had heat sinks and thermal grease, it was just faulty relays. I purchased relays from a reputable source and haven't had any issues since.

Race season is over, i now have some time to finish the brewery. I just got my second auberins PID in the mail yesterday for the BK. Ill be removing the 3500w element from the BK and just using a 5500w on a PID with an alarm for manual control near boil. The 3500w just had too much heat density for boiling high gravity beers. The HLT will stay with both elements to help temp ramping speed. I plan to move the brewery this fall and polish up the kegs a bit too.

Hit up the MT with a flap wheel today. Need to buy some finer grit flap wheels and sandpaper to get a better shine. Goo gone aka lemon or orange terpenes worked perfectly for removing sticker glue.

I picked up eight 6' lengths of 14 ga stranded wire in different colors to wire up my bigger box. Should make wiring a breeze.

I picked up eight 6' lengths of 14 ga stranded wire in different colors to wire up my bigger box. Should make wiring a breeze.

Making minor changes to the system. Got some line loc for the Herm's recirc. Also finally got some nice 13" glass lids to keep dust out between brews. BCS controller is the only item on my xmas list

Similar threads

- Replies

- 20

- Views

- 849

- Replies

- 0

- Views

- 214

- Replies

- 23

- Views

- 2K

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)