cactusgarrett

Well-Known Member

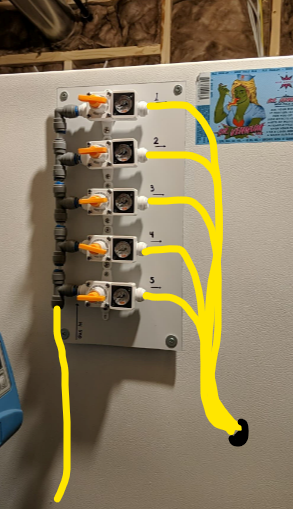

I just converted my gas side over to 4mm EVAbarrier and DuoTight fittings, and I'm hoping someone can lend some insight as to whether or not I have a leak.

I hit the system with pressure, and with quick disconnects off the kegs, shut off valves (before the in-line regulators) and let it sit overnight. When I come back to it the next morning, there's a noticeable pressure drop on the gauges, and when I charge the lines again (turn on valves before the regulators) the gauges jump back up to the set pressure. Disconnected from kegs and isolated from the gas tank, should these lines hold/maintain pressure? Is this indicative of a leak? I tested the QDs by submerging in a glass of water (no leaks there), but obviously I can't do that to the in-line check valve or in-line regulator junctions.

Overall, the setup is similar to this (including the blue clips). After the gas tank and regulator, there are 5 independent lines, so I'll illustrate just one for simplicity:

Gas tank/regulator -> DuoTight in-line ball valve -> DuoTight in-line regulator -> DuoTight check valve -> DuoTight low profile ball lock gas QD

I hit the system with pressure, and with quick disconnects off the kegs, shut off valves (before the in-line regulators) and let it sit overnight. When I come back to it the next morning, there's a noticeable pressure drop on the gauges, and when I charge the lines again (turn on valves before the regulators) the gauges jump back up to the set pressure. Disconnected from kegs and isolated from the gas tank, should these lines hold/maintain pressure? Is this indicative of a leak? I tested the QDs by submerging in a glass of water (no leaks there), but obviously I can't do that to the in-line check valve or in-line regulator junctions.

Overall, the setup is similar to this (including the blue clips). After the gas tank and regulator, there are 5 independent lines, so I'll illustrate just one for simplicity:

Gas tank/regulator -> DuoTight in-line ball valve -> DuoTight in-line regulator -> DuoTight check valve -> DuoTight low profile ball lock gas QD

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)