NervousDad

BFM

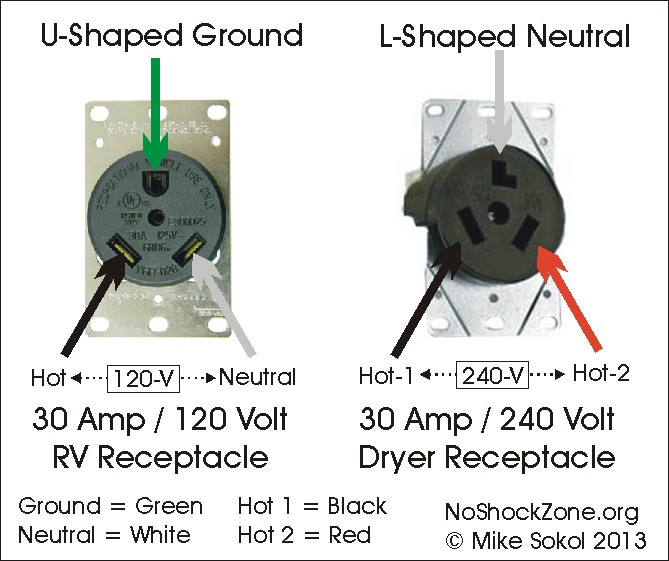

So I'm moving my dryer so I can make room for my future electric setup and found that the wire that is running to it is a 10-2 with a ground? It's connected to two 30a breakers. The ground was wired to the outlet along with a hot and a black and white wire.

Does the mean my dryer was only running on 120v? I'm hoping that they didn't have the ground wire hooked up to the breaker as a hot wire, but we have upgraded our breaker box and I can't imagine that they did that.

I do have to run my dryer twice to dry heavy stuff I wonder if that was the reason.

Does the mean my dryer was only running on 120v? I'm hoping that they didn't have the ground wire hooked up to the breaker as a hot wire, but we have upgraded our breaker box and I can't imagine that they did that.

I do have to run my dryer twice to dry heavy stuff I wonder if that was the reason.