Morrey

Well-Known Member

I hear you with the condensation issues while cold crashing. Here in central texas I have the same problem but just deal with it by sopping up with shop towels. On the covers back patio so I don’t care about the water issue as much.

On another note, please share your thoughts and pix once you get the Ss Spunding valve set up. In the thread I started on that piece someone chimed in that our PRV could be set by the end user which makes this Ss part more attractive in theory. But like anything I want to hear from one of us before pulling the trigger. Which version did you purchase?

I'll be glad to post back once the spunding valve comes in. I bought the one with the scaled indicator so I can set easily....but of course I'll test the scale along with the pressure gauge for accuracy. According to USPS tracking, I'll have it tomorrow so I can test it out next weekend with a brew.

I emailed Ss and asked the following question(s) regarding setup:

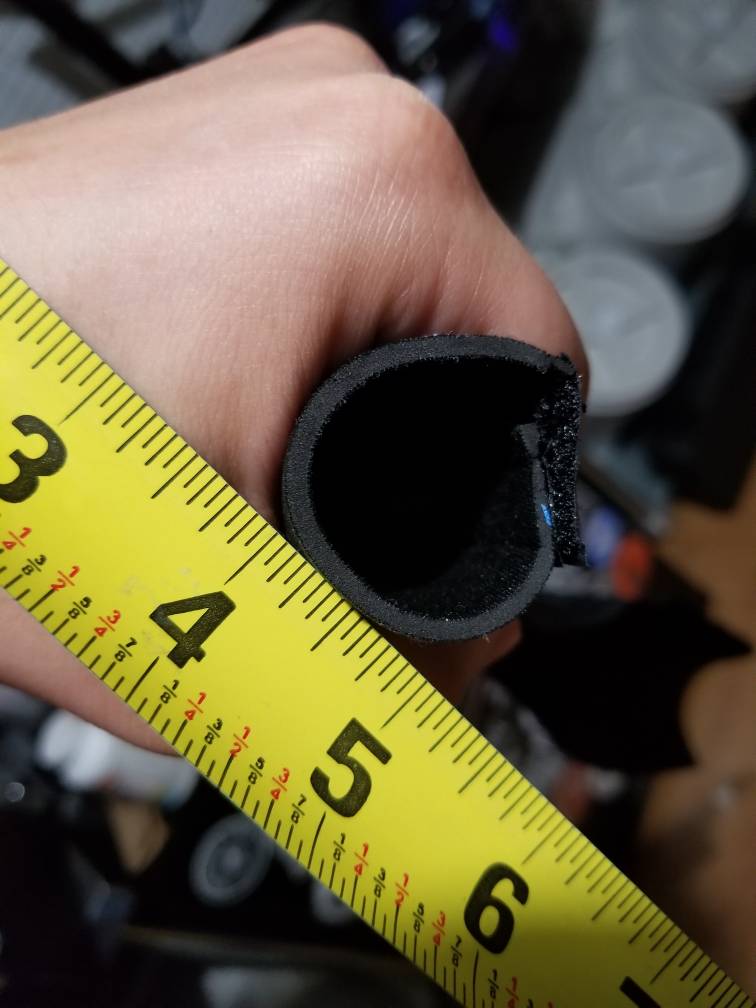

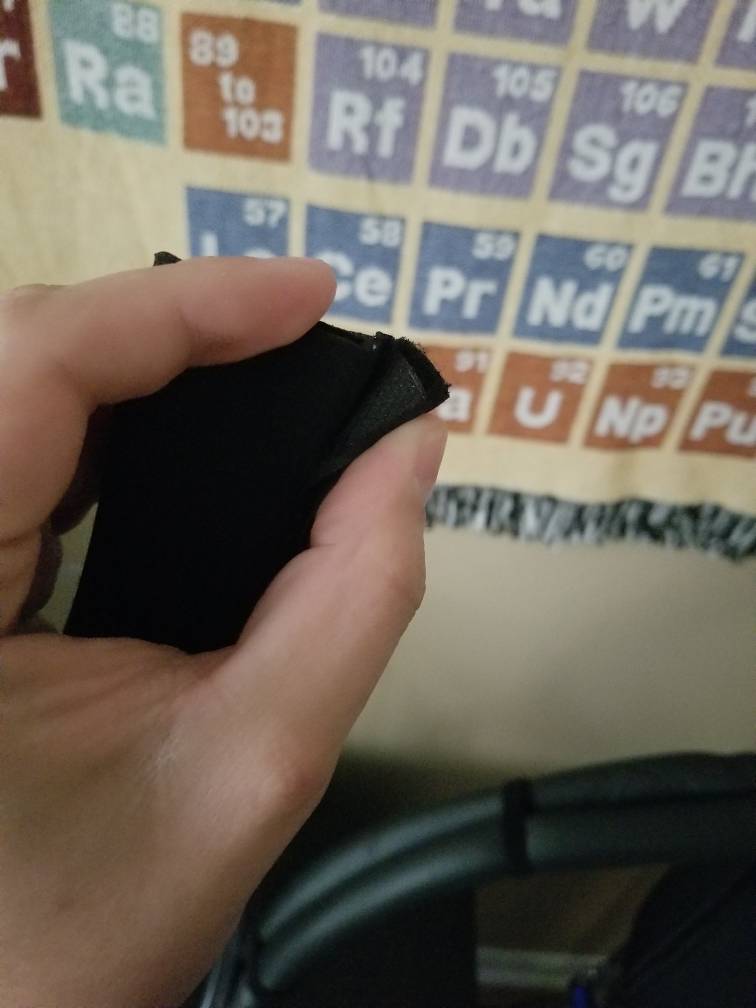

Me - Would I be able to purchase a 3" to 1.5" TC reducer and use the spunding valve in place of the 18 psi relief valve? Ss - We suggest leaving your 18 psi relief valve in place to protect your tank. You will need a micro Tee and a micro elbow to use the spunding valve on the BO cane.

With that said, I bought the manifold components instead of the reducer.

Me - Will the small amount sanitizer in the cup around the valve blow out at high krausen? Ss - We suggest you adjust the spunding valve with a high pressure setting until krausen has dropped while leaving your BO valve open. After high krausen had dropped, close your BO valve and set the spunding valve to your preference.

I have been experimenting with fermenting under pressure by just closing the BO valve, but then the PRV will blow at 18 psi unless I can get to the BO valve and relieve some of the pressure before that happens. I'm not sure at this point, but I figure I'll set the valve maybe 5 - 7 psi or around that area. I think that 18 psi is too high and may cause some issues with the yeast alto not sure. I'll probably go lower and see how that works out.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)