If I posted in the wrong forum and this should be in the DIY forum, Mods please move it for me!

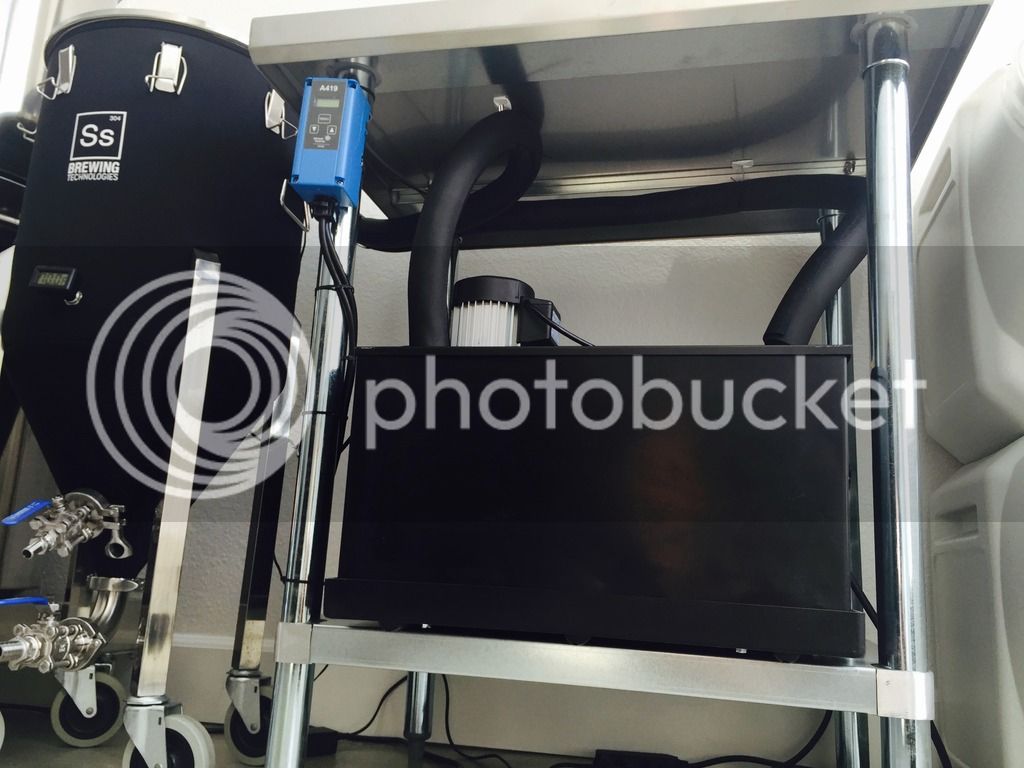

So for the last 4 months or so Ive been using my chest freezer/keezer as a chill water source for my SS Brewtech 14 gallon conical with FTSS temp control system. Essentially I rigged it up as displayed in the picture; by installing customized bulkheads through the freezer wall and locating the pump in a 5 gallon corny keg. Since Im located in Southern California, my fermentation area fluctuates between the high 60s and mid-to-high 70s ambient, depending on the season and time of day/night.

As a result, holding ale fermentation temps has not been a problem, as I can easy maintain a low 60s primary fermentation point for cleaner ales or hefes etc. The problem came about when I attempted to crash cool or hold lager temps. Furthermore, now that were moving into the spring/summer months the load on the freezer and subsequent compressor cycles have been more and more frequent.

Since I would keep the freezer/chill source on the edge of freezing, the initial temp drop I received was fantastic. But upon further use, I found that the freezer wasnt able to produce a recovery rate that was sufficient enough to keep the conical at lower temps for extended periods. I even tried adding crappy vodka in an attempt to lower the freezing temp of the chill water, and therefore the freezer thermostat, but I experienced very little incremental gain. The problem is obviously more structural.

Since the evaporator coils are merely chilling the air inside the freezer, and that in turn would remove heat from the chill water inside the keg, the cycle in which to maintain and recover a low enough temp simply took too long. The other problem is that I only have 5 gallons of chill water to cool 12ish gallons of beer. Plus the smaller compressors in most chest freezers, 1/8-1/6 HP, could not provide the BTUs/Hr to remove the heat that was absorbed by the chill water.

I found that the compressor ran much longer and more often since it was naturally not designed to remove any more heat than was lost naturally by the freezers insulation. I should preface that by saying that I think most users with the brew bucket and 7 gallon Chronical should be able to get by with this setup, but for the 14 gallon/half barrel Chronicals, there is no way the freezer can handle the load.

So my goals for a new system were essentially two-fold:

1) I wanted to invest in a long term solution that I can use for all the potentially necessary fermentation/cellaring functions, including lagering, crash cooling

etc.

2) I wanted the system to be expandable so that I can potentially daisy-chain more fermenters, so excess cooling capacity was a consideration

I looked at a ton of the DIY window A/C unit glycol chillers on HBT but I felt that they were never designed to serve the intended purpose, and through my eyes they appeared in pictures to be inefficient, clunky, and just plain god-awful looking. I know that many will disagree, yet its common knowledge that refrigerant high/low pressure configurations in addition to compressor, evaporator, and condenser size/configuration are designed with inherent efficiencies for a specific application.

So I started researching alternatives and decided to use a trunk-line power-pack type glycol chiller, which in turn provides more than enough BTUs/Hr to chill and crash cool 3-4 times the amount of beer I was seeking to ferment. Just to verify my hunches I jetted over to probrewer.com to read up on the amount of BTUs/hr that many commercial breweries were using to maintain and crash their insulated conicals. Now I realize that the SS Brewtechs conical neoprene jacket doesn't have the same insulation factor that a double-wall jacketed poly-injected conical does, but its a point of reference worth researching.

Using this type of calculation (

http://amchiller.com/size-brewery-chiller/ ) I would need at least 213 BTUs/Hr to pull down the fully-loaded fermenter by 41 degrees (75 minus 34) over 24 hours. Which isnt very much, but that doesnt factor in active fermentation and/or insulation loss very precisely

So I figured I would triple that figure and I could essentially turn the conical into a block of ice within 12 hours.

Looking at most of the glycol power packs on the market, they are extremely oversized and also extremely expensive for this purpose. I didnt need to have a 7-10 gallon glycol bath, I didnt need 5000+ BTUs/Hr, and I didnt want to spend over $1K. Moreover, I was concerned about energy efficiency, and hoped that due to decreased compressor runtime and cycling, the chiller would be just-as or more energy efficient than my chest freezer rig.

So I scoured the interweb and chose what I thought was the best price when calculated at dollars per BTU/Hr. I purchased the BVL Controls Eco 33, 1/3 HP 3 gallon bath chiller from Rapids Wholesale (no sales tax plus free shipping!). For those that dont know, or think that BVL is a no-name brand, they are a Canadian company that has been an OEM supplier of Micro Matics for forever and a day

. So the quality and fit-and-finish was everything that I expected for the price. For a point of reference the compressor/condenser pack was nearly the same Tecumseh units that UBC are using in their chillers.

The Eco 33 unit provides 2300 BTU/Hr of cooling capacity, and also has a pump (50GPH) that can actually be utilized in place of the small FTSS system 12v pump. The flow rates align pretty well, and it wasnt extremely oversized for this purpose.

(In the pics I have it configured for the FTSS pump)

After receiving the chiller, I rewired the pump from a constant on configuration to a Johnson A419 temp controller, with the Johnson controls thermocoupling fitting perfectly into the supplied FTSS thermowell. That way the Chillers thermostat will maintain the glycol temp in the high 20s-low 30s and the Johnson will maintain the conicals temp at any desired factor within about 5-10 degrees above the glycol temp. I also have some added peace of mind since the chillers pump is designed to be run constantly; so I dont have to worry about long run times (except for the fact that I dont want the beer to freeze in the conical). The only downside is the pump is louder since its not dampened by being submerged in the glycol bath. Im still running tests on which pump and thermostat combo I prefer more.

The other convenient feature of this chiller is that it came plumbed from the factory with 3/8 barbs (more than likely for a glycol draught tower), so the chiller links right up to the FTSS coil, no modifications needed. I chose to go with thick wall silicone tubing (3/16 wall), due to the fact it remains extremely flexible even at sub-freezing temps, plus its an added layer of insulation. It wont harden like PVC or vinyl tubing.

Although Ive only processed one batch through the new system, my initial impressions are extremely positive. The compressor barely has to cycle in comparison to the chest freezer to maintain temps, and the temp drops extremely rapidly in a crash-cool scenario. In my tests using just water, it can drop the temp 30+ degrees inside of an hour if Im really pushing it! Although it may be just one mans opinion, this system is a must have for warm weather climates, or for homebrewers fermenting inside a garage where ambient temps can spike into the 80s and 90s.

The only downside is the added noise, which sounds like an average run of the mill hermetically sealed compressor on top of a good sized bedroom fan running at the same time. Ideally, this would be in a garage, so you wouldnt ever notice the sound, and the plus side is that it doesnt have to run very long.

I realize that many homebrewers will think this design is crazy overkill, and that I could have achieved the same results for less than half the cost. Yet those same people should identify with the fact that Im pretty picky when it comes to my brewing equipment, and realize that there are countless other home brewers that would be interested in emulating my setup. Furthermore, I think this system will offer me a good amount of expandability.

Im happy to field questions or run additional tests for anyone interested. Yet, I think that for what Im seeking to accomplish with my home brewery that it couldnt get any more perfect. Cheers!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)