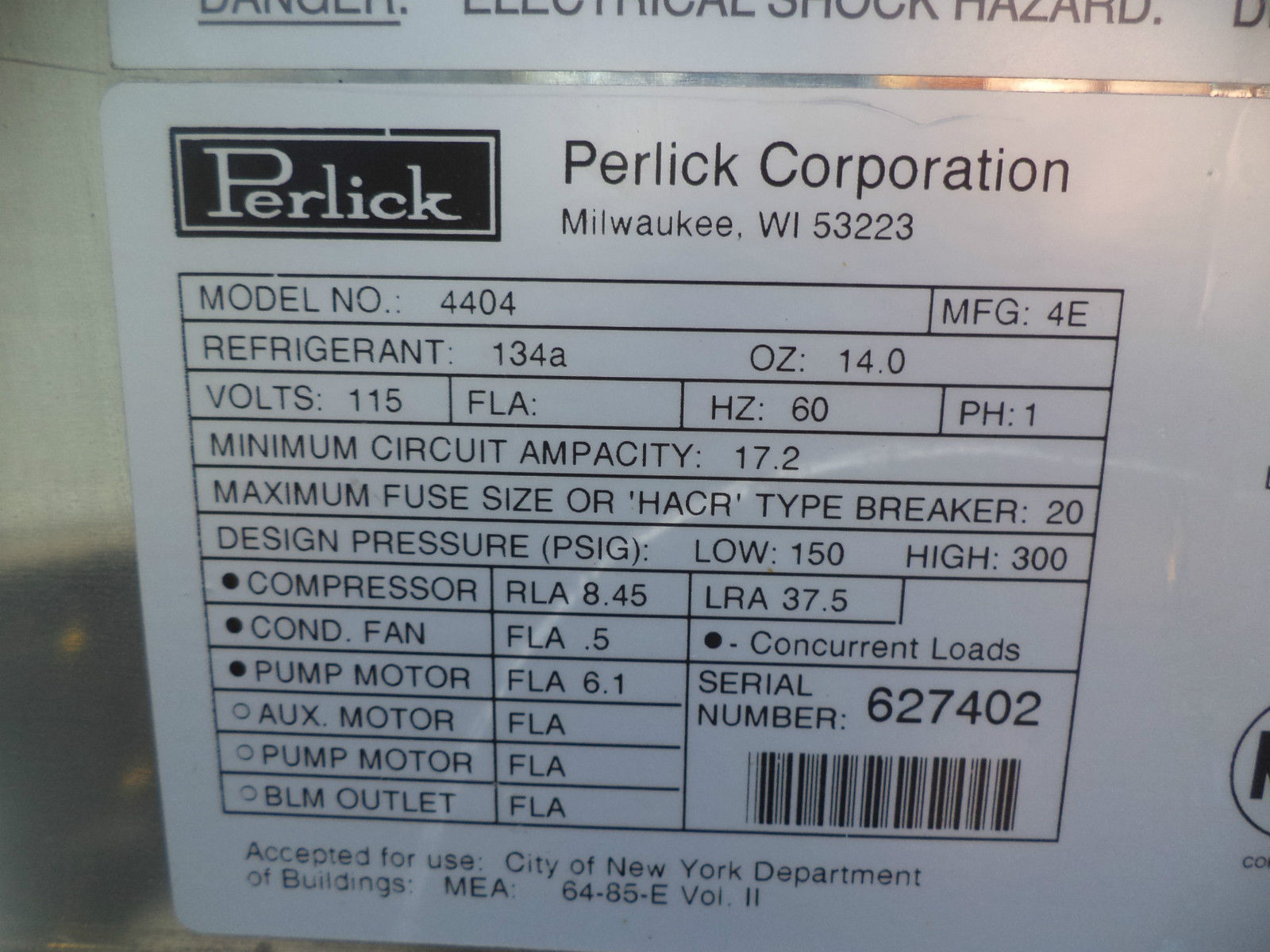

Well, with unbelievable luck, I found a Perlick 4404 chiller on eBay for $549 plus $164 shipping. I was about to pull the trigger on the system from Rapids when I found this.

I uncrated it last night and started a test run with it. Its 2300 BTU and claims 4000+ BTU heat rejection according to their literature. It will cool the glycol to 20F. It cools 12 gal of H2O which is right at 100# approx. 20 degrees per hour. Unfortunately the hysteresis is set at 4 degrees from the factory or I could use the built in pump with their temperature control. Im sure there is a way to reprogram the hysteresis in the controller, but Perlick advises against this. 4 degree drift would defeat the purpose of using a chiller in the first place.

I have no idea if the way the Perlick works is germane to other manufacturers, but this sucks the glycol through a plate & frame HX with refrigerant on the other side of the plates then discharges off the pump. The return goes through the John Guest fittings near the pump. For proper (i.e. rapid) cooling, it would appear that the circulation pump needs to stay running to draw the glycol over the chiller.

Therefore, Im debating whether or not to manage the pump flow with my Kegco temp controller, or to install my FTSS pump in the reservoir to run the SSBT fermenter, and use the main pump to recirc the coolant through a loop and use the Kegco temp controller I use for my 7 gal fermenter to open a 115V solenoid when it calls for cooling. The second thought has been to run the main pump constantly as a recirc loop and see if I can find a solenoid to run off the FTSS module.

I uncrated it last night and started a test run with it. Its 2300 BTU and claims 4000+ BTU heat rejection according to their literature. It will cool the glycol to 20F. It cools 12 gal of H2O which is right at 100# approx. 20 degrees per hour. Unfortunately the hysteresis is set at 4 degrees from the factory or I could use the built in pump with their temperature control. Im sure there is a way to reprogram the hysteresis in the controller, but Perlick advises against this. 4 degree drift would defeat the purpose of using a chiller in the first place.

I have no idea if the way the Perlick works is germane to other manufacturers, but this sucks the glycol through a plate & frame HX with refrigerant on the other side of the plates then discharges off the pump. The return goes through the John Guest fittings near the pump. For proper (i.e. rapid) cooling, it would appear that the circulation pump needs to stay running to draw the glycol over the chiller.

Therefore, Im debating whether or not to manage the pump flow with my Kegco temp controller, or to install my FTSS pump in the reservoir to run the SSBT fermenter, and use the main pump to recirc the coolant through a loop and use the Kegco temp controller I use for my 7 gal fermenter to open a 115V solenoid when it calls for cooling. The second thought has been to run the main pump constantly as a recirc loop and see if I can find a solenoid to run off the FTSS module.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)