Ahks

Well-Known Member

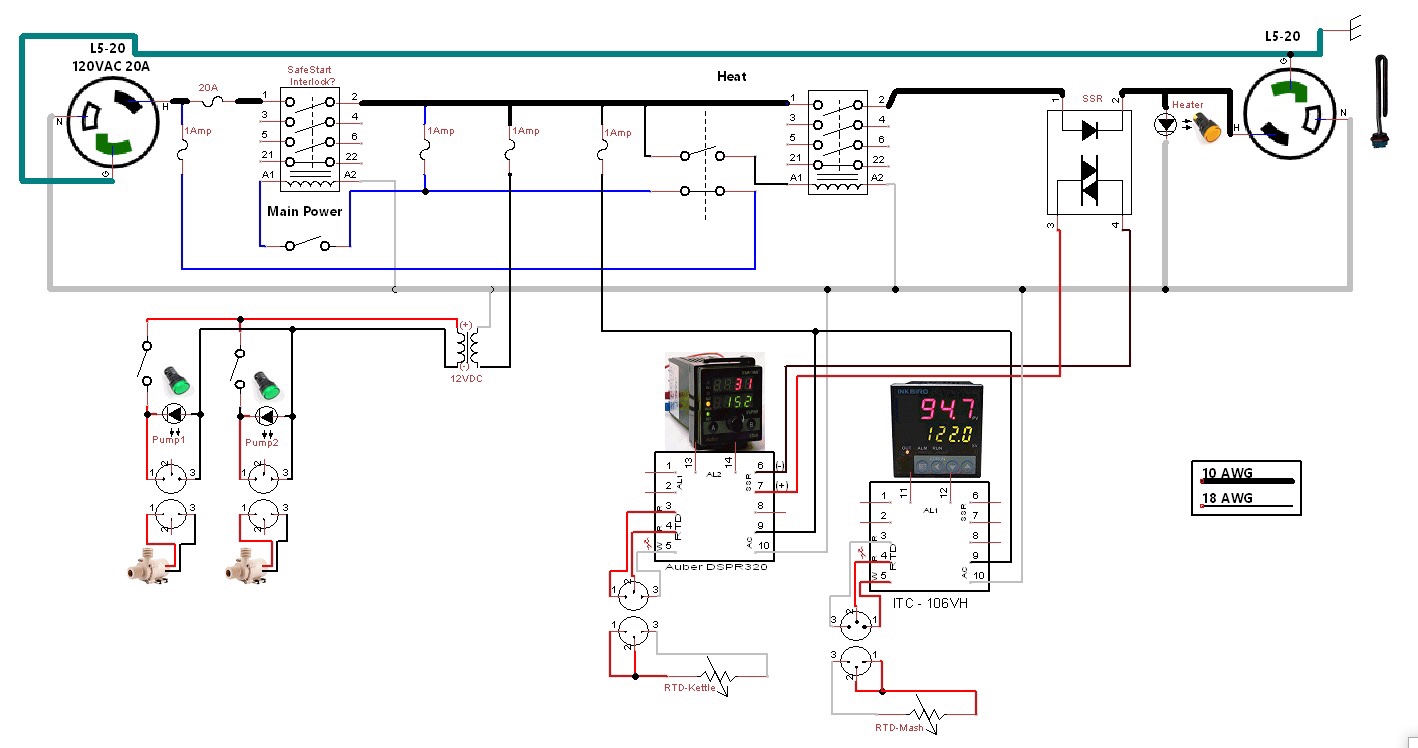

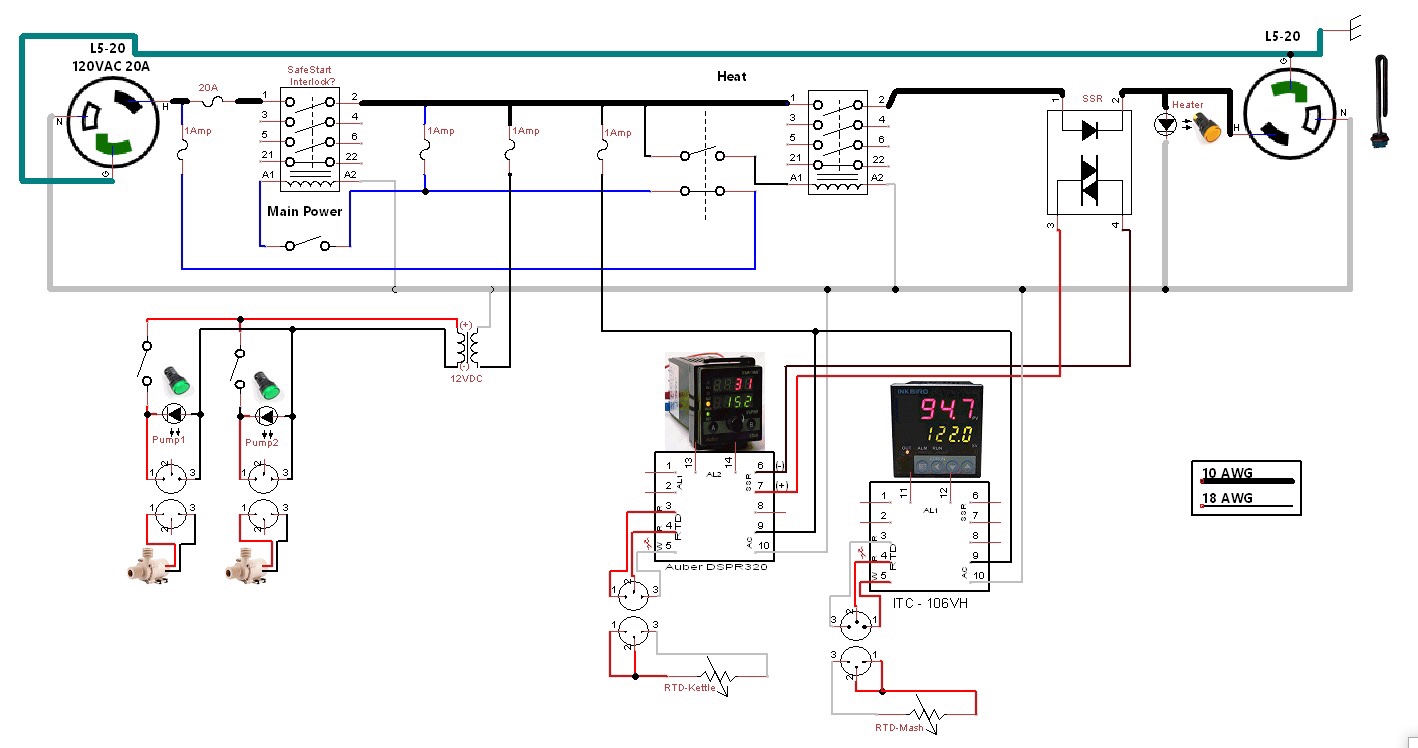

System is a 120V 20A on a dedicated circuit with a 20A GFCI. It uses a 2.2kW element for 2.5 - 5 gallon batches.

Setup is 2 vessel similar to the BrewEasy design using similar kettle geometry to a Grainfather since I know they don't have too much trouble boiling wort for 5 gallon batches on 120V. I'm leaving myself the option for 2 pumps, but I'll probably only use 1 most of the time.

Since I'm looking at Auber's DSPR320, I'll probably spend some time programming it and therefore the panel will probably be on when the system is dry. I think I worked in a safe start to prevent a dry fire on start up. Not worried about the pumps. They're noisy enough to let me know if they're on, the element, not so much.

Anything missing? Any complaints? See something stupid?

Setup is 2 vessel similar to the BrewEasy design using similar kettle geometry to a Grainfather since I know they don't have too much trouble boiling wort for 5 gallon batches on 120V. I'm leaving myself the option for 2 pumps, but I'll probably only use 1 most of the time.

Since I'm looking at Auber's DSPR320, I'll probably spend some time programming it and therefore the panel will probably be on when the system is dry. I think I worked in a safe start to prevent a dry fire on start up. Not worried about the pumps. They're noisy enough to let me know if they're on, the element, not so much.

Anything missing? Any complaints? See something stupid?

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)