kombat

Well-Known Member

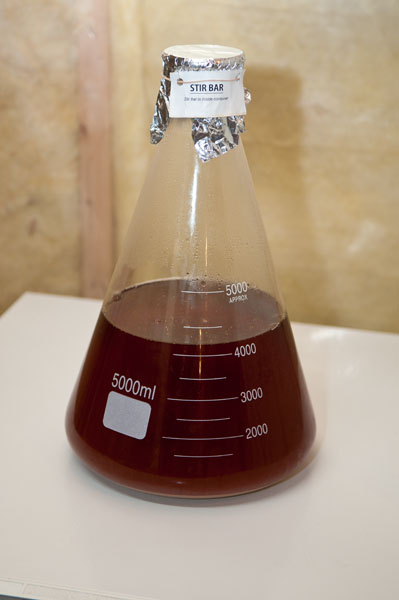

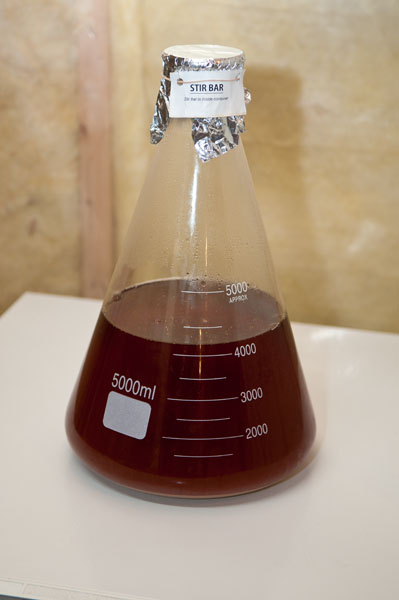

Everybody loves photo threads, right? I did a double brew day yesterday and thought I'd take photos along the way to show my setup and how I brew two batches on the same day. I brewed an Irish Red Ale and an Oatmeal Stout. I used Wyeast Irish Ale yeast for both, and I made the starter Wednesday night, intending to split it between both batches. It rode the stir plate for 36 hours, then I cold-crashed it Friday morning. Here's a shot of the brewing area of my basement.

My Maris Otter buckets were empty, so I had to open a fresh sack and refill them.

I took the yeast out of the fridge to allow it to slowly warm up to room temperature while I brewed.

Weighing out the grains for the Irish Red Ale

The grains all together in the bucket, awaiting milling.

Milling with my trusty Barley Crusher.

That's a lot of roasted barley!

A couple scoops of rice hulls for stuck-mash insurance.

A look down my street. Gorgeous weather! I do the actual brewing in the garage because I use propane.

The equipment setup in my garage.

I was preheating the mash tun with hot tap water while I was getting the grains ready.

Doughing in the first batch, the Irish Red Ale.

Giving everything a good stir.

I cover my grain bed with aluminum foil to help it hold temperature. I punch a bunch of holes in it with the temperature probe from my turkey fryer set, so that when I recirculate, the wort doesn't disturb the grain bed.

I overshot my temperature a little bit, so I added a bit of cold water to get it to settle right where it was supposed to be.

While the Irish Red Ale was mashing, I prepped the grains for the second batch, the Oatmeal Stout.

It's not an Oatmeal Stout without oatmeal!

The milled grains with the oatmeal. I added rice hulls to this batch, too.

Drawing the sparge water for the Irish Red Ale, sprinkling in 1/4 of a Campden tablet

Here I'm heating the sparge water while recirculating to clear the wort. The smaller white pail is my grant. Once the wort is clear enough, I turn off the pump and redirect the output from the grant into the pot on the floor (it has volume markings etched onto the inside) to accurately measure how much wort I'm collecting.

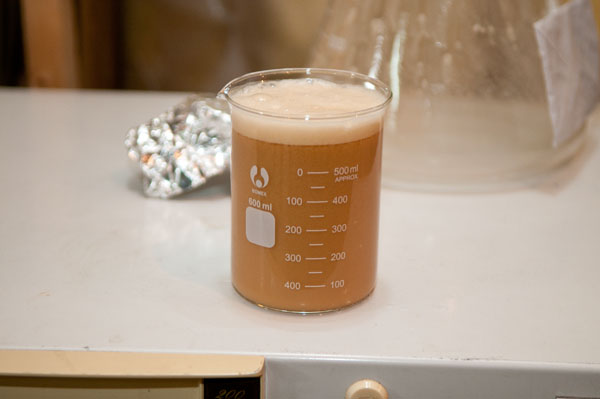

The wort in the grant.

Recirculating back to the mash tun. You can see how the foil protects the grain bed.

Wort's clear, collecting it in the pot now.

Perfect timing - the sparge water is hot enough.

Dumped in the sparge water and gave it another good stir. Note that I'm propping up the back end of the mash tun to increase how much wort I'm able to drain from it.

First runnings of the Irish Red Ale, already heating up while I recirculate and collect the second runnings.

Everything is in the pot now, just got to heat it to a boil.

The trick to maximizing your time when doing a double-brew day is the second burner. Here I'm using my old turkey fryer burner to heat up the strike water for the second batch (the Oatmeal Stout) while my main burner is heating the Irish Red Ale to a boil.

Dumping the grains from the Irish Red Ale into the compost bin.

Mash tun cleaned, doughing in the second batch, the Oatmeal Stout, while the Irish Red Ale boils. Stirring, hitting the temperature, etc.

The Oatmeal Stout is mashing in the cooler while the Irish Red Ale is boiling.

Setting up the chilling hardware.

Our tap water is pretty warm this time of year, so I set up a cooler full of ice water and a second pump to take over chilling once the wort temperature drops below 80.

Getting ready to collect waste water and use it to clean. The "HOT WATER OUT" goes into a bucket with a scoop of Oxyclean in it.

Adding some hops to the Irish Red Ale.

Getting the carboy ready.

Irish moss - almost done the boil.

Meanwhile, the second burner is heating the sparge water for the second batch.

Before the end of the boil, I run some of the wort through the chiller and hoses to sanitize them.

Boil finished, I move the pot up onto the table (because I'm going to siphon it into the carboy) and begin chilling. I recirculate the wort back into the boil kettle until it reaches the desired temperature.

Recirculating and chilling.

Perfect. Low-to-mid 60's. According to the timestamps on the photos, that took 9 minutes.

Siphoning into the carboy.

Time to start recirculating the second batch while I quickly clean the boil kettle.

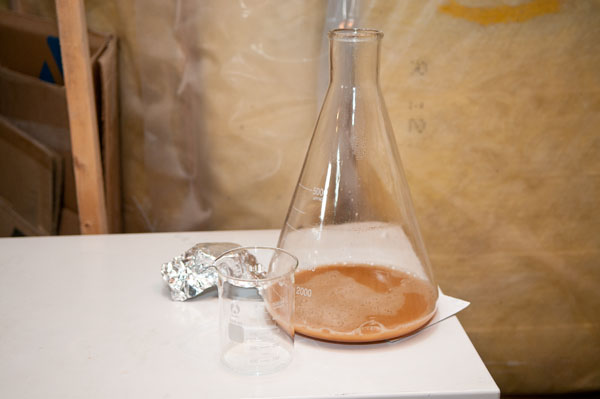

First runnings of the second batch.

The first batch gets cozy in a water bath.

I aerate my batches with a Fizz-X rod on a drill.

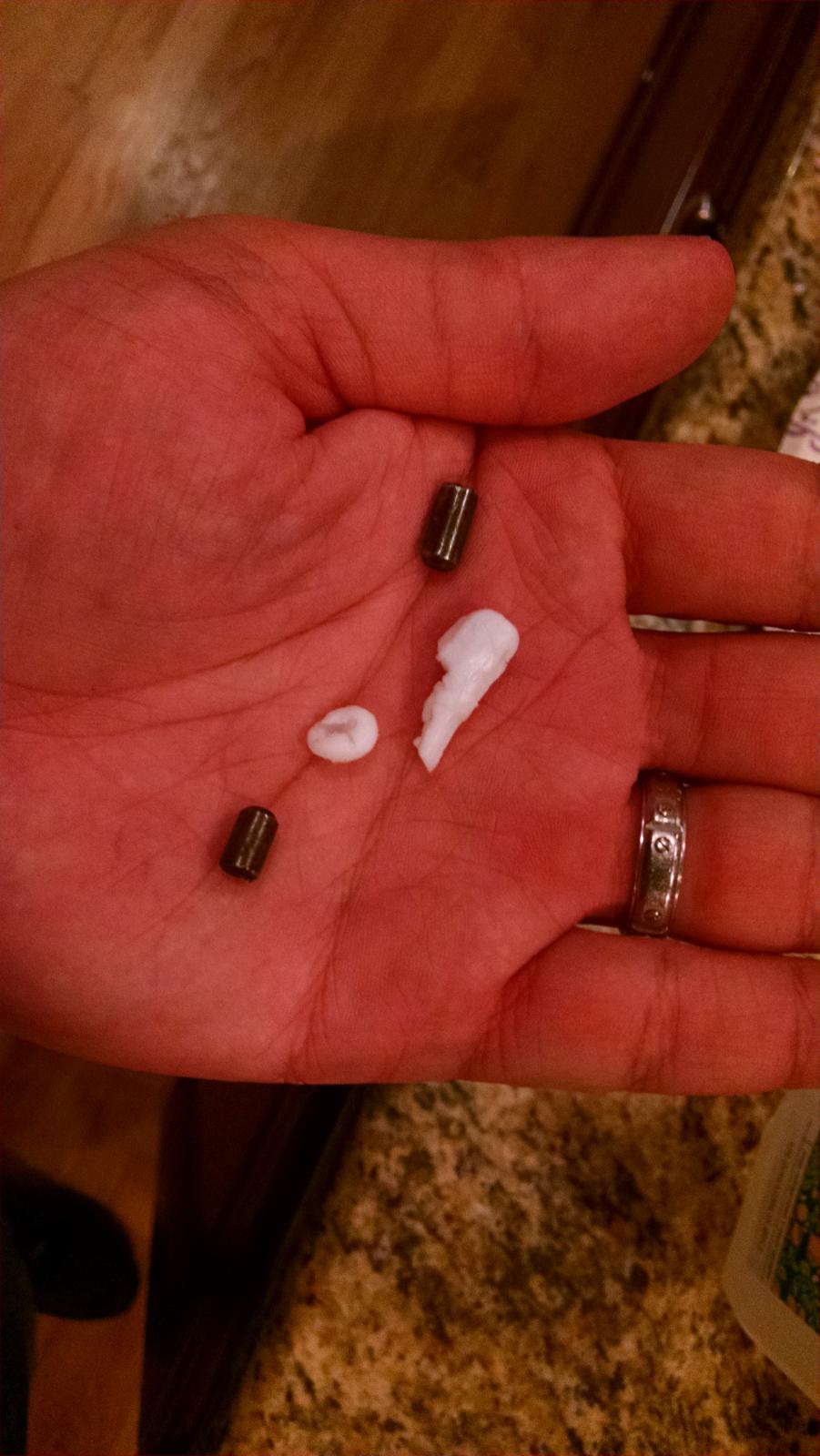

The yeast had warmed up by now, so I decanted the spent wort, leaving just enough to swirl up the yeast cake.

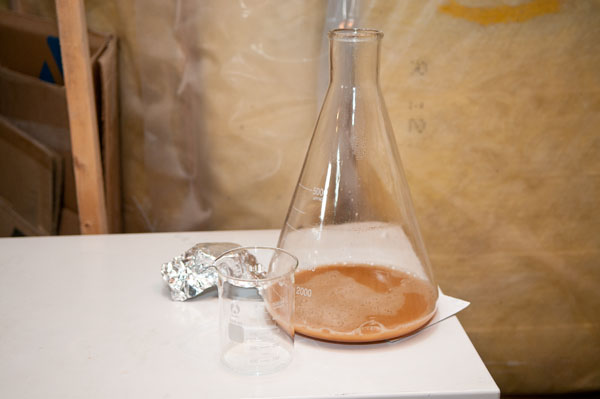

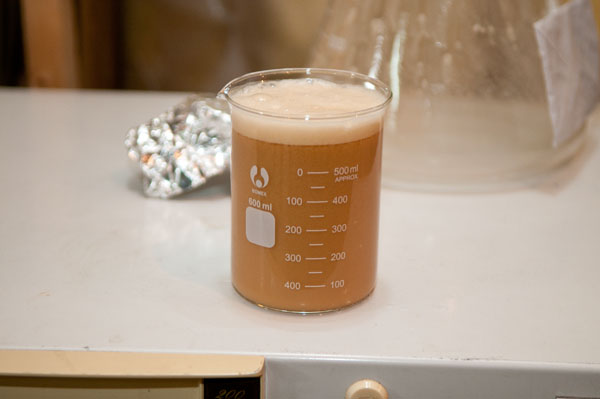

I transferred the yeast into a graduated beaker so I can evenly split it between the batches.

I pitched half into the Irish Red Ale, then covered it with sanitized foil until the Oatmeal Stout is ready for it.

Blowoff tube affixed into a pail of Star San

A while later, the Oatmeal Stout was finished and got the same treatment.

By now, the yeast had started to separate a little, so I swirled it up a bit and pitched the remainder into the Oatmeal Stout.

Oatmeal Stout, aerated. I overshot my volume a bit on this one, so it got a blowoff tube too.

The two batches side-by-side (with a Cascade IPA from last week in the back), covered with wet t-shirts.

They are both bubbling away like crazy today, can't wait to taste them!

My Maris Otter buckets were empty, so I had to open a fresh sack and refill them.

I took the yeast out of the fridge to allow it to slowly warm up to room temperature while I brewed.

Weighing out the grains for the Irish Red Ale

The grains all together in the bucket, awaiting milling.

Milling with my trusty Barley Crusher.

That's a lot of roasted barley!

A couple scoops of rice hulls for stuck-mash insurance.

A look down my street. Gorgeous weather! I do the actual brewing in the garage because I use propane.

The equipment setup in my garage.

I was preheating the mash tun with hot tap water while I was getting the grains ready.

Doughing in the first batch, the Irish Red Ale.

Giving everything a good stir.

I cover my grain bed with aluminum foil to help it hold temperature. I punch a bunch of holes in it with the temperature probe from my turkey fryer set, so that when I recirculate, the wort doesn't disturb the grain bed.

I overshot my temperature a little bit, so I added a bit of cold water to get it to settle right where it was supposed to be.

While the Irish Red Ale was mashing, I prepped the grains for the second batch, the Oatmeal Stout.

It's not an Oatmeal Stout without oatmeal!

The milled grains with the oatmeal. I added rice hulls to this batch, too.

Drawing the sparge water for the Irish Red Ale, sprinkling in 1/4 of a Campden tablet

Here I'm heating the sparge water while recirculating to clear the wort. The smaller white pail is my grant. Once the wort is clear enough, I turn off the pump and redirect the output from the grant into the pot on the floor (it has volume markings etched onto the inside) to accurately measure how much wort I'm collecting.

The wort in the grant.

Recirculating back to the mash tun. You can see how the foil protects the grain bed.

Wort's clear, collecting it in the pot now.

Perfect timing - the sparge water is hot enough.

Dumped in the sparge water and gave it another good stir. Note that I'm propping up the back end of the mash tun to increase how much wort I'm able to drain from it.

First runnings of the Irish Red Ale, already heating up while I recirculate and collect the second runnings.

Everything is in the pot now, just got to heat it to a boil.

The trick to maximizing your time when doing a double-brew day is the second burner. Here I'm using my old turkey fryer burner to heat up the strike water for the second batch (the Oatmeal Stout) while my main burner is heating the Irish Red Ale to a boil.

Dumping the grains from the Irish Red Ale into the compost bin.

Mash tun cleaned, doughing in the second batch, the Oatmeal Stout, while the Irish Red Ale boils. Stirring, hitting the temperature, etc.

The Oatmeal Stout is mashing in the cooler while the Irish Red Ale is boiling.

Setting up the chilling hardware.

Our tap water is pretty warm this time of year, so I set up a cooler full of ice water and a second pump to take over chilling once the wort temperature drops below 80.

Getting ready to collect waste water and use it to clean. The "HOT WATER OUT" goes into a bucket with a scoop of Oxyclean in it.

Adding some hops to the Irish Red Ale.

Getting the carboy ready.

Irish moss - almost done the boil.

Meanwhile, the second burner is heating the sparge water for the second batch.

Before the end of the boil, I run some of the wort through the chiller and hoses to sanitize them.

Boil finished, I move the pot up onto the table (because I'm going to siphon it into the carboy) and begin chilling. I recirculate the wort back into the boil kettle until it reaches the desired temperature.

Recirculating and chilling.

Perfect. Low-to-mid 60's. According to the timestamps on the photos, that took 9 minutes.

Siphoning into the carboy.

Time to start recirculating the second batch while I quickly clean the boil kettle.

First runnings of the second batch.

The first batch gets cozy in a water bath.

I aerate my batches with a Fizz-X rod on a drill.

The yeast had warmed up by now, so I decanted the spent wort, leaving just enough to swirl up the yeast cake.

I transferred the yeast into a graduated beaker so I can evenly split it between the batches.

I pitched half into the Irish Red Ale, then covered it with sanitized foil until the Oatmeal Stout is ready for it.

Blowoff tube affixed into a pail of Star San

A while later, the Oatmeal Stout was finished and got the same treatment.

By now, the yeast had started to separate a little, so I swirled it up a bit and pitched the remainder into the Oatmeal Stout.

Oatmeal Stout, aerated. I overshot my volume a bit on this one, so it got a blowoff tube too.

The two batches side-by-side (with a Cascade IPA from last week in the back), covered with wet t-shirts.

They are both bubbling away like crazy today, can't wait to taste them!