I believe beer was made before electricity, propane and even thermometers existed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Do you really need a pid

- Thread starter applescrap

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

stamandster

undefined member

I believe beer was made before electricity, propane and even thermometers existed.

But was a it as good or diverse or repeatable?

alphaomega

Well-Known Member

- Joined

- Jul 10, 2013

- Messages

- 1,041

- Reaction score

- 461

There's been a lot of healthy discussion in this thread since I was here last, and many well reasoned arguments.

I agree with pretty much everything said.

I just want to add that something like the EZBoil (or DSPR1) is a much better choice than an SSVR.

An SSVR is basically a dimmer, and will produce an awful lot of electromagnetic noise. The knob will also control the power in a very non linear way. Finally, the pot will carry mains voltage, which is also not so nice.

An SSR and a controller (such as the EZBoil or the DSPR1 or even a cheap eBay PWM generator that can produce a frequency that is at most around 1Hz) is a better choice.

It not that an SSVR won't work. It will, it is simply not the best tool available.

I agree with pretty much everything said.

I just want to add that something like the EZBoil (or DSPR1) is a much better choice than an SSVR.

An SSVR is basically a dimmer, and will produce an awful lot of electromagnetic noise. The knob will also control the power in a very non linear way. Finally, the pot will carry mains voltage, which is also not so nice.

An SSR and a controller (such as the EZBoil or the DSPR1 or even a cheap eBay PWM generator that can produce a frequency that is at most around 1Hz) is a better choice.

It not that an SSVR won't work. It will, it is simply not the best tool available.

applescrap

Be the ball!

Apparently the man who made mine and this one passed away. Sad to hear. Googled dspr1, yes that looks perfect and gives many ssr choices.

View attachment 1474896898331.jpg

View attachment 1474896898331.jpg

I went the simple route with my electric setup. I made two small control panels out of the plastic large boxes from still dragon. One has their DIY controller kit which is their packaged SSVR setup. I believe the rheostat does not carry mains voltage, the resistance itself is what controls the SSVR, if I remember correctly. I use that for the boil kettle with 5500W element.

I also have a basic temperature controller for my HLT instead of a PID. It took me a long time to find a 220v Fahrenheit controller, and it ended up being shipped directly from China. I use that to feed into a 40amp SSR which controls the 5500W element in the HLT.

Both relays are on heatsinks with fans pulling air across them.

I really like my setup, and enjoy the simplicity of it.

I also have a basic temperature controller for my HLT instead of a PID. It took me a long time to find a 220v Fahrenheit controller, and it ended up being shipped directly from China. I use that to feed into a 40amp SSR which controls the 5500W element in the HLT.

Both relays are on heatsinks with fans pulling air across them.

I really like my setup, and enjoy the simplicity of it.

alphaomega

Well-Known Member

- Joined

- Jul 10, 2013

- Messages

- 1,041

- Reaction score

- 461

I believe the rheostat does not carry mains voltage, the resistance itself is what controls the SSVR, if I remember correctly.

I dare you to lick the terminals of the pot when plugged in

No, really don't do that.

No matter how hard you believe, the pot will still carry mains, and needs to be sized and insulated accordingly.

I'm glad you're happy with your setup, but still, if someone is in the market for a power controller for their boil kettle, an SSR and slow PWM signal generator, is the better choice.

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$33.95

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Bridgeview Beer and Wine Supply

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$27.29 ($13.64 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

BeardedBrews

Well-Known Member

Man Apple, you're all over on this topic...

I've always been confused by the way people phrase this question when the basics are always the same:

"Do I really have to buy X-Y-Z component? Couldn't I just get by without it?"

This question isn't unique to electric, which is why it always confuses me when people who have done stove-top or turkey burner miss the point. You need a heat source, and a way to turn it on and off. After that, anything more is strictly there to make your brew day easier.

You could JB-Weld a $15 range cord directly onto the contacts on a $15 ebay element then screw it into a hole in your kettle with a $3 nut/o-ring and a bit of solder for the ground wire. Control the element by plugging and un-plugging it in a GFCI outlet on the wall. Done. This would be the equivalent of having a turkey burner with a non-adjustable regulator. Full Blast and Off is all you get, and that's all you need to make beer.

In reality, most of us appreciate the ability to turn down the power on our kettle. The most basic approach here is to get a SSVR and a dial which will make your element work like a turkey burner with an adjustable regulator or your stove-top.

Since we're talking about things we like, it's also nice to know the temperature in the kettle. Use your old-fashioned hands and hold a kitchen thermometer in there, or wire a thermocouple into a digital display, it hardly matters.

And then we get into the "well, but wouldn't it be cool if?" territory. Wouldn't it be cool if my kettle would just go to whatever temperature I wanted and then stay there. Grab the tail end of that thermocouple you bought, and poke it into a controller (PID, EZBoil, PLC, Arduino, PC, STC-1000, Ranco, anything) and now you are automated. You'll still need a basic SSR to connect and disconnect the power when the controller says so.

I've always been confused by the way people phrase this question when the basics are always the same:

"Do I really have to buy X-Y-Z component? Couldn't I just get by without it?"

This question isn't unique to electric, which is why it always confuses me when people who have done stove-top or turkey burner miss the point. You need a heat source, and a way to turn it on and off. After that, anything more is strictly there to make your brew day easier.

You could JB-Weld a $15 range cord directly onto the contacts on a $15 ebay element then screw it into a hole in your kettle with a $3 nut/o-ring and a bit of solder for the ground wire. Control the element by plugging and un-plugging it in a GFCI outlet on the wall. Done. This would be the equivalent of having a turkey burner with a non-adjustable regulator. Full Blast and Off is all you get, and that's all you need to make beer.

In reality, most of us appreciate the ability to turn down the power on our kettle. The most basic approach here is to get a SSVR and a dial which will make your element work like a turkey burner with an adjustable regulator or your stove-top.

Since we're talking about things we like, it's also nice to know the temperature in the kettle. Use your old-fashioned hands and hold a kitchen thermometer in there, or wire a thermocouple into a digital display, it hardly matters.

And then we get into the "well, but wouldn't it be cool if?" territory. Wouldn't it be cool if my kettle would just go to whatever temperature I wanted and then stay there. Grab the tail end of that thermocouple you bought, and poke it into a controller (PID, EZBoil, PLC, Arduino, PC, STC-1000, Ranco, anything) and now you are automated. You'll still need a basic SSR to connect and disconnect the power when the controller says so.

Didn't read whole thread, but I run my e-kettle with a pulse width modulator. Did not design circuit myself - have electrical engineer father. Simpler than PID (which I DO have on my espresso maker), but you have to keep an eye on things. Less autonomous.

Solid State Variable Relay is basically an adjustable SCR that limits the AC waveform to deliver less than peak power. It's the functional modern solution to that VARIAC (speaking of fancy acronyms).

A lot of the discussion about need vs want vs overkill comes down to perceived effort and cost matched up against utility. I doubt anyone would brew on an EZboil based controller and later determine that it's a waste of technology and makes brewing harder or less enjoyable. It's like a manual power knob with the added (and optional mind you) temp control and digital temperature readout. It's been mentioned before, but it's a minimal increment cost over the most rudimentary power control devices.

If it matter at all, I don't sell controllers yet so I have no financial gain in promoting any of this stuff.

A lot of the discussion about need vs want vs overkill comes down to perceived effort and cost matched up against utility. I doubt anyone would brew on an EZboil based controller and later determine that it's a waste of technology and makes brewing harder or less enjoyable. It's like a manual power knob with the added (and optional mind you) temp control and digital temperature readout. It's been mentioned before, but it's a minimal increment cost over the most rudimentary power control devices.

If it matter at all, I don't sell controllers yet so I have no financial gain in promoting any of this stuff.

Solid State Variable Relay is basically an adjustable SCR that limits the AC waveform to deliver less than peak power. It's the functional modern solution to that VARIAC (speaking of fancy acronyms).

A lot of the discussion about need vs want vs overkill comes down to perceived effort and cost matched up against utility. I doubt anyone would brew on an EZboil based controller and later determine that it's a waste of technology and makes brewing harder or less enjoyable. It's like a manual power knob with the added (and optional mind you) temp control and digital temperature readout. It's been mentioned before, but it's a minimal increment cost over the most rudimentary power control devices.

If it matter at all, I don't sell controllers yet so I have no financial gain in promoting any of this stuff.

I am sure that an EZBoil setup would cost a small fraction of the cost of a 240VAC 50A Variac (and weigh only a tiny fraction as much). I use Variacs all the time when servicing and restoring vintage radio gear - but only because PWM isn't compatible with power transformers. I wouldn't use them if there were an economical modern equivalent that would work.

Last edited:

I recently ran across these on eBay:

http://www.ebay.com/itm/131408591986

http://www.ebay.com/itm/140553985193

http://www.ebay.com/itm/140553987088

They include a special type of Solid State Relay (SSR) that takes a potentiometer as an input and outputs a proportional amount of power.

If I were going to build the type of setup you're talking about, this is what I'd use. (40+ years experience in electronics, here!)

I was considering adding one of these in the same box as a PID controller, so I could use either PID or manual power control. (Most PIDs have a manual control option, however.)

(Edit: Oops... I replied before reading the whole thread. I see something like this has already been mentioned!)

http://www.ebay.com/itm/131408591986

http://www.ebay.com/itm/140553985193

http://www.ebay.com/itm/140553987088

They include a special type of Solid State Relay (SSR) that takes a potentiometer as an input and outputs a proportional amount of power.

If I were going to build the type of setup you're talking about, this is what I'd use. (40+ years experience in electronics, here!)

I was considering adding one of these in the same box as a PID controller, so I could use either PID or manual power control. (Most PIDs have a manual control option, however.)

(Edit: Oops... I replied before reading the whole thread. I see something like this has already been mentioned!)

On Variacs... Yes that would work, too. However a 2000 Watt Variac is going to be very large, very heavy, and very expensive!

On Variacs... Yes that would work, too. However a 2000 Watt Variac is going to be very large, very heavy, and very expensive!

A 2KW isn't too bad; maybe 40 pounds and $100 (I bought a new one recently). VERY inefficient, though. I doubt that it would really deliver 2KW for very long without the paint melting. Most electric brewing solutions use much more than 2KW, of course.

augiedoggy

Well-Known Member

Am I calling the potentiometer wrong? Basically just a power dial. Drew a picture, sorry its not very good. My hopes are that I can save someone a lot of money and time if they brew like me.

you have it right... with this setup you would basically brew exactly the same as you would with a banjo /propane burner.... best guess and adjusting everything manually.

This was the best way to get that done on a controller I built a while back... I had a pid for one element and this for the boil kettle.

http://www.ebay.com/itm/140553987088?_trksid=p2060353.m1438.l2649&ssPageName=STRK:MEBIDX:IT

augiedoggy

Well-Known Member

I recently ran across these on eBay:

http://www.ebay.com/itm/131408591986

http://www.ebay.com/itm/140553985193

http://www.ebay.com/itm/140553987088

They include a special type of Solid State Relay (SSR) that takes a potentiometer as an input and outputs a proportional amount of power.

If I were going to build the type of setup you're talking about, this is what I'd use. (40+ years experience in electronics, here!)

I was considering adding one of these in the same box as a PID controller, so I could use either PID or manual power control. (Most PIDs have a manual control option, however.)

(Edit: Oops... I replied before reading the whole thread. I see something like this has already been mentioned!)

this is what I used for a second controller I built to sell but never did anything with.. seemed like a quality setup.

While most will disagree with me, it is entirely possible to brew electric with nothing more than a gfi power source, a properly rated switch and en element sized for a nice boil at 100% power.

I've done it for years, long before there was any info on the web w/ people using pids, pumps etc etc, back in the early days of e brewing 8-10 years ago can't really remember.

7.75 gallon batch in a 15 gallon kettle with two 2000w 120v elements provides a nice boil at full power.

.

Yeah. My panel build was delayed when I realized that I had a high, but within reason, boil off rate using one 2000w element for 5 gallon batches and two elements for 10 gallon batches. I prefer having better control with the completed panel, but I was able to keep the pipeline full during the process.

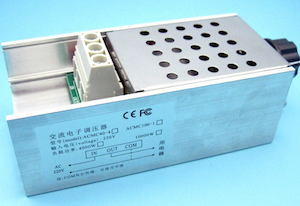

What would be the downside in using something like this?

10000W SCR Voltage Regulator Speed Controller Dimmer Thermostat AC 110V 220V

http://s.aliexpress.com/eiqaY3yi

10000W SCR Voltage Regulator Speed Controller Dimmer Thermostat AC 110V 220V

http://s.aliexpress.com/eiqaY3yi

What would be the downside in using something like this?

10000W SCR Voltage Regulator Speed Controller Dimmer Thermostat AC 110V 220V

http://s.aliexpress.com/eiqaY3yi

I'm guessing that if you take that apart, you'll find this inside:

http://www.ebay.com/itm/140553987088

(Or something functionally equivalent!)

I'm guessing that if you take that apart, you'll find this inside:

http://www.ebay.com/itm/140553987088

(Or something functionally equivalent!)

Looks to be so. Expect some caps and resistors as well.

applescrap

Be the ball!

If that will work I would be willing to sell my contoller and save the money back. What else would I need?

DavidD

Well-Known Member

- Joined

- Oct 9, 2013

- Messages

- 64

- Reaction score

- 6

Lots of great perspectives and dialogue. Thanks to the OP for bringing it up. I recently just finished a 3 tier gravity fed brewing stand with mounted propane burners. However, I still have all the parts for an electric setup that got put on hold because of not being able to add any new circuit breakers on our new (to us, built in 1960s) house.

All that to say, with the discussion here, I'm considering revisiting finishing an electric setup off existing 120V circuits. Thanks

All that to say, with the discussion here, I'm considering revisiting finishing an electric setup off existing 120V circuits. Thanks

HerkimerBrewer

Member

- Joined

- Feb 7, 2015

- Messages

- 23

- Reaction score

- 2

I use the controller kit from StillDragon.com Works like a charm...simple as can be. After the wort comes to a boil, I dial it back to 65%.....off to the races.

- Joined

- Aug 8, 2012

- Messages

- 192

- Reaction score

- 49

I recently built out an electric system to what I believe you're trying to do. I too was unable to put in any more breakers (which sucks) so I had to use my dryer outlet.

I can dial down for 5 gallons when needed and boil up to 12 with no problem.

I'd love to (and been meaning to) share some pics but I'm at work right now. Will update soon.

I can dial down for 5 gallons when needed and boil up to 12 with no problem.

I'd love to (and been meaning to) share some pics but I'm at work right now. Will update soon.

augiedoggy

Well-Known Member

I believe an SCR setup is different than an ssvr setup... I may be wrong here but from memory I believe the ssvr still works like a pwm by adjusting the time length of the full power pulses and the SCR actually adjusts the voltage output to a lower voltage....I'm guessing that if you take that apart, you'll find this inside:

http://www.ebay.com/itm/140553987088

(Or something functionally equivalent!)

There are a number of folks here that use those SCR units also found on ebay and more than one have found they are designed for 50hz power and they dont have as linear of control with 60hz power from what Ive read. Also the internal fuse trace and holder has a tendency to burn up on the board over time.

augiedoggy

Well-Known Member

off topic but are you located in Herkimer NY by chance? I travel through there for work often.I use the controller kit from StillDragon.com Works like a charm...simple as can be. After the wort comes to a boil, I dial it back to 65%.....off to the races.

I believe an SCR setup is different than an ssvr setup... I may be wrong here but from memory I believe the ssvr still works like a pwm by adjusting the time length of the full power pulses and the SCR actually adjusts the voltage output to a lower voltage....

There are a number of folks here that use those SCR units also found on ebay and more than one have found they are designed for 50hz power and they dont have as linear of control with 60hz power from what Ive read. Also the internal fuse trace and holder has a tendency to burn up on the board over time.

Whether an SCR circuit works with 50hz or 60hz or whether it offers linear control is a function of the design of the control circuit. Personally, I'd buy the SSVR/Pot/Heatsink and package it myself rather than trust the Chinese SCR controller.

SSRs and SSVRs usually have SCRs or TRIACs (essentially a bi-directional SCR) inside.

augiedoggy

Well-Known Member

Whether an SCR circuit works with 50hz or 60hz or whether it offers linear control is a function of the design of the control circuit. Personally, I'd buy the SSVR/Pot/Heatsink and package it myself rather than trust the Chinese SCR controller.

SSRs and SSVRs usually have SCRs or TRIACs (essentially a bi-directional SCR) inside.

hmm well all the ones on ebay and amazon like the one linked were built for the 50hz market... Im just repeating what I read in another thread where someone was asking why they were having those issues with them and the guy from brumatic explained it was because of the 50-60hz difference.. apparently he looked into using them on his panels.

and as far as the SSR using triacs... I am not so sure they all do, especially the ones most home brewers buy.. some use use an optical switch with a Thyristor gate although I admit I dont know much about them but I did a little reading on the differences when there was a lot of discussion on the fake fotek clones a while back.

I made the same choice and went with the ssvr and pot from ebay myself... for my main system I will be replacing my mypin pid with manual mode with an auber ezboil unit for its other features like timed boil and internal alrms and such ..besically more toys for my brewing enjoyment and to make the process as consistent as possible between brews. I totally understand wanting to keep it simple though.

All that to say, with the discussion here, I'm considering revisiting finishing an electric setup off existing 120V circuits. Thanks

Do it! I have a 2x1500 watt set up. Been using that wattage for about 1.5 years now and I love it. I can brew anywhere I can get to two separate 15 amp circuits, which is never a problem.

And I can make batches as small as 3 gallons and up 10 gallons at 1.050, no sparge. Two weekends ago I did a 9 gallon no sparge Helles Bock with OG of 1.067.

Boiling that much water is no problem with two 120v elements. When I hit boiling I leave one element full blast and turn the other element down to 30% for 6 gallon batches. I use 50% for 10 gallon batches.

I'll say it again. Do it!

hmm well all the ones on ebay and amazon like the one linked were built for the 50hz market... Im just repeating what I read in another thread where someone was asking why they were having those issues with them and the guy from brumatic explained it was because of the 50-60hz difference.. apparently he looked into using them on his panels.

That's possible... however, if the triggering circuit is well designed, 50 or 60 Hz won't matter. (The cheap ones may not be well designed!)

and as far as the SSR using triacs... I am not so sure they all do, especially the ones most home brewers buy.. some use use an optical switch with a Thyristor gate although I admit I dont know much about them but I did a little reading on the differences when there was a lot of discussion on the fake fotek clones a while back.

An SCR and a TRIAC are both types of thyristors... Most have some kind of optical isolation internally.

I made the same choice and went with the ssvr and pot from ebay myself...

I think this is the easiest, most cost-effective solution.

Similar threads

- Replies

- 11

- Views

- 969