Say Jaybird,

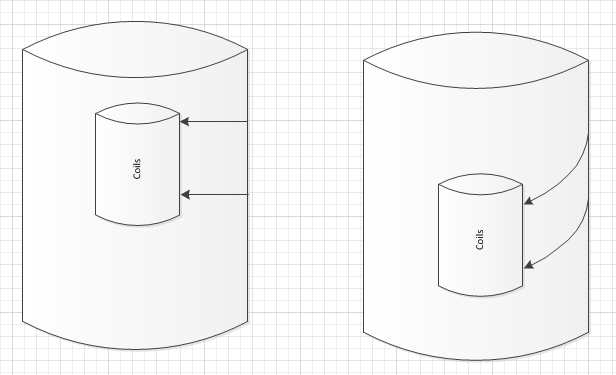

Looking for a canning jar yeast harvester, 1.5 t/c cap like you sell on your site, but add 2 ss tubing and Cornelius keg posts adapters similar to what @PlinyTheMiddleAged did in this thread (https://www.homebrewtalk.com/forum/...rub-yeast-harvester-for-conical.510704/page-3). Thank David.

Looking for a canning jar yeast harvester, 1.5 t/c cap like you sell on your site, but add 2 ss tubing and Cornelius keg posts adapters similar to what @PlinyTheMiddleAged did in this thread (https://www.homebrewtalk.com/forum/...rub-yeast-harvester-for-conical.510704/page-3). Thank David.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)