Have you fermented with this yet? I was thinking of something along these lines to keep sanitizer or yeast from being pulled back into the fermenter. But I was thinking of having a spunding valve and ball lock connector on the triclover, and adding a thermowell. Then you set the regulator to about 1-2 PSI and the spunding valve just barely above that. Then when you cold crash the pressure is replaced from the CO2 tank and there is no suckback at all.

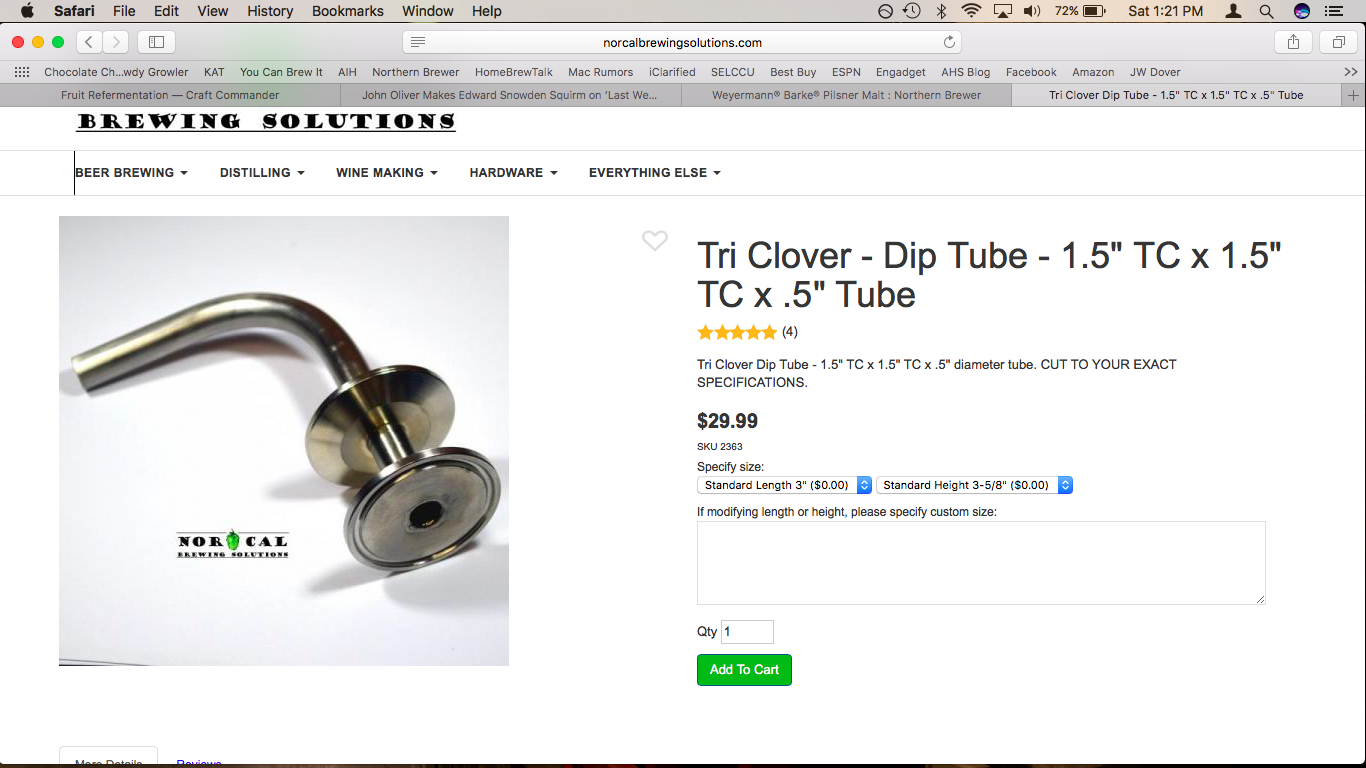

Jay, could you make this? 2" triclover with a 1/4" tee for the spunding valve and this:

https://www.brewhardware.com/product_p/npttokegpost.htm

1/4" tee: https://www.amazon.com/gp/product/B...s2&tag=becausebeer-20&linkId=67ADUDDXYXLI63MO

then add a thermowell?

I haven't yet. Should be brewing in the next week or two. I'll try to post pics or a video once active fermentation happens.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)