Agtronic

Well-Known Member

Hey guys,

For many people, one of the exciting aspects of brewing beer is to always be looking for ways to improve from batch to batch. As you may know, controlling fermentation temperature is a great way to improve the flavor profile of your brew and helps you make more consistent beers batch to batch. Temperature control also allows you to delve into the world of Lagers.

I built this a few months ago and wanted to share it here in case it might be helpful to anyone. I had been putting off getting a temp controller because the commercials units were a bit expensive for me, and I had read mixed reviews about how well they worked.

Then I came a cross the STC-1000+ thread started by alphaomega. When I saw how inexpensive the STC-1000 was, I decided right then and there that it was time to get going on this project.

The STC-1000+ project is downright amazing. I didn't get into that with mine (yet), but plan to in the future. You do not need to get into the electronics aspect if you just want simple temp control!

I used to fiddle around with electronics (a long time ago) but haven't had much free time in recent years with the garage/fabrication business. Now I have a bit more time and this post convinced me to start dabbling again.

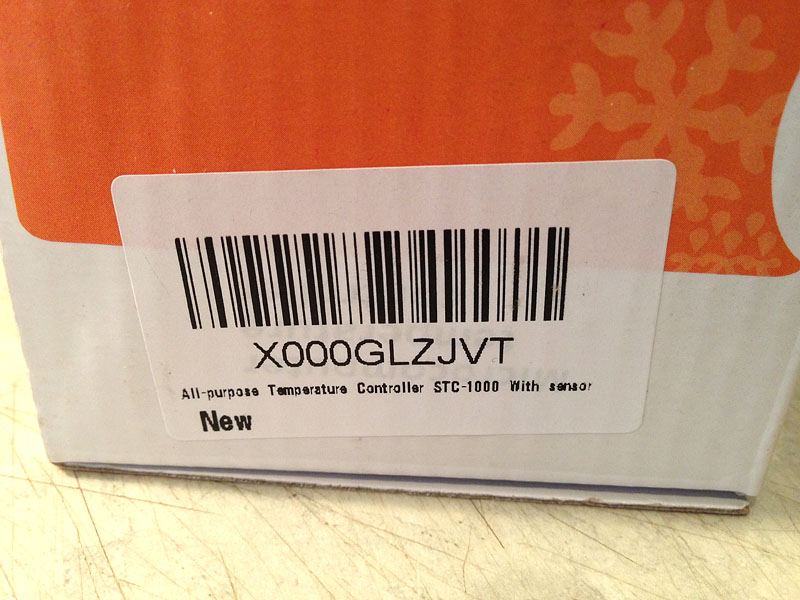

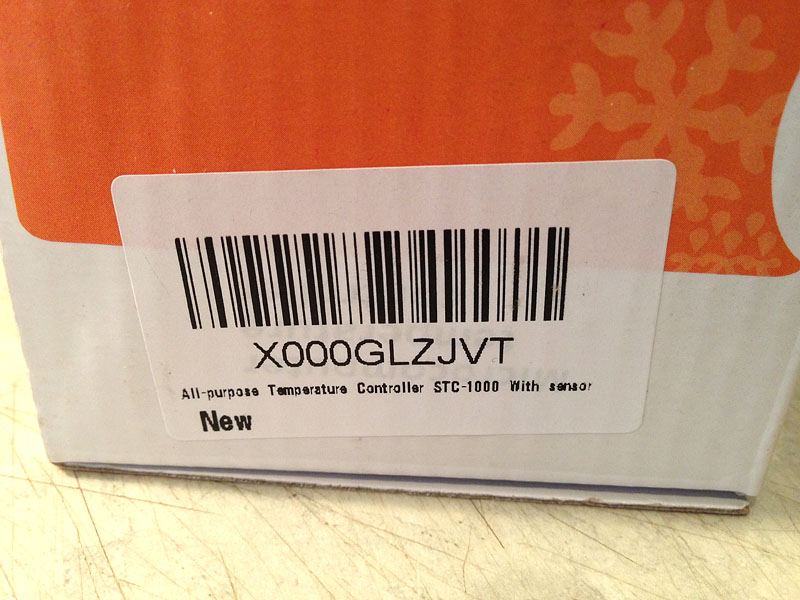

I'm in Canada, so a lot of what I read on forums is a bit different, especially with respect to sourcing "the goods". On a Friday, I ordered an STC-1000 from Amazon.ca (which as I understand it, uses a different distribution network than the US amazon.com does.) I received it on Monday. (Lightening fast shipping.)

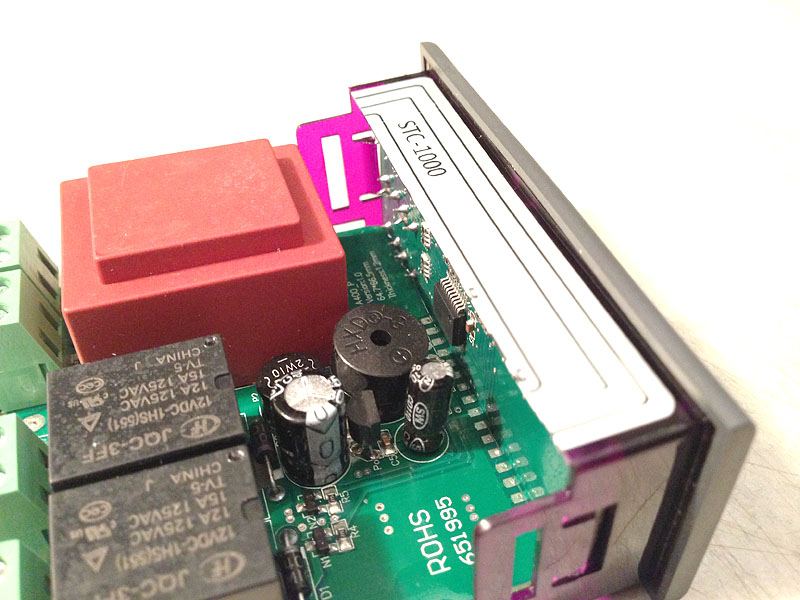

Here are some pics from when I received the unit:

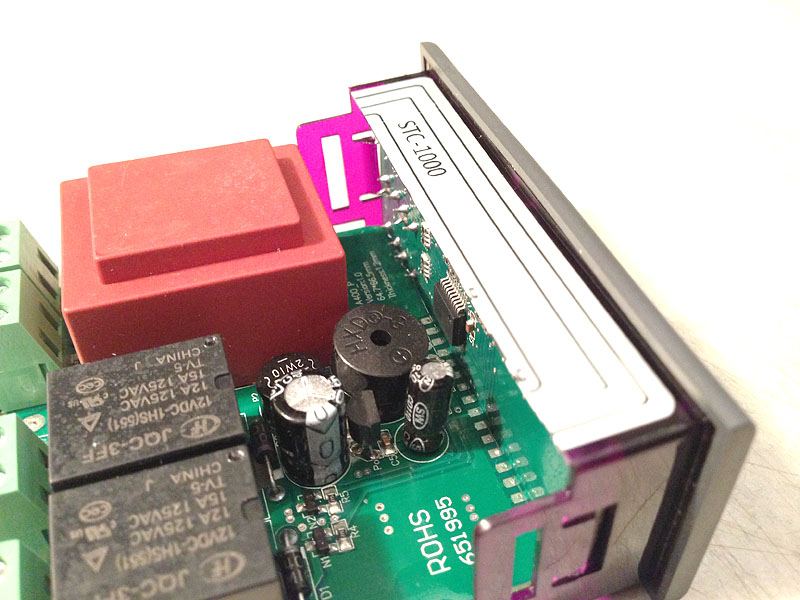

Opened it up to check for compatibility with the STC-1000+ project:

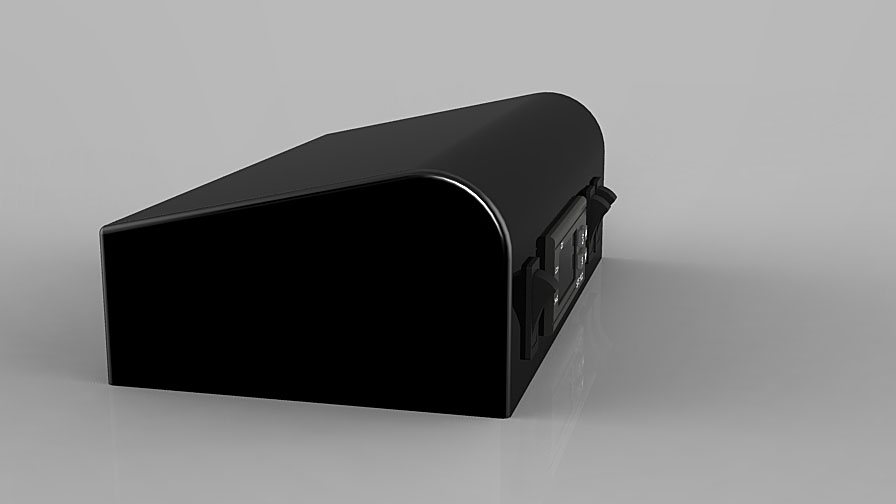

I went to the local electronics store and picked up a project box I felt would fit the project best. I came a cross this one from Hammon Canada.

Components:

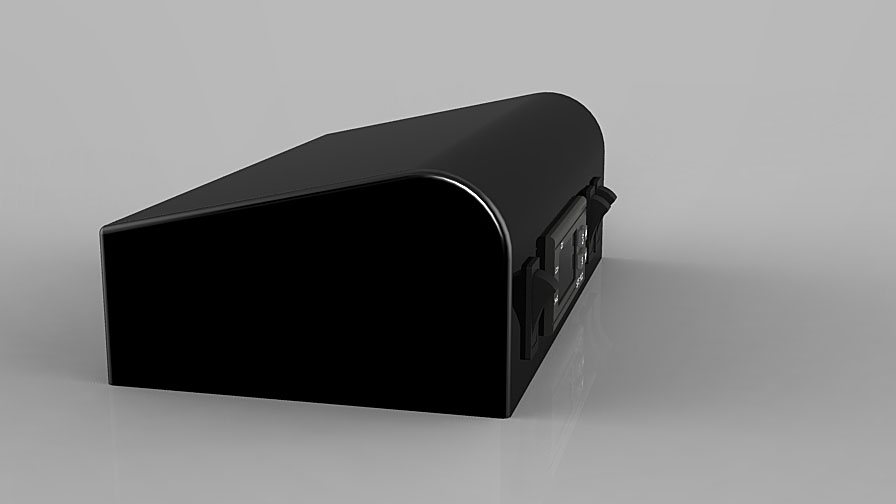

Next I modeled the box and the components to try different ideas for a clean look. I guess I went a little nuts with the details. (ADD / hyperfocus)

STC-1000:

Then I set out to build it.

Hope this might help others looking for ideas on how to set theirs up. I welcome all questions!

For many people, one of the exciting aspects of brewing beer is to always be looking for ways to improve from batch to batch. As you may know, controlling fermentation temperature is a great way to improve the flavor profile of your brew and helps you make more consistent beers batch to batch. Temperature control also allows you to delve into the world of Lagers.

I built this a few months ago and wanted to share it here in case it might be helpful to anyone. I had been putting off getting a temp controller because the commercials units were a bit expensive for me, and I had read mixed reviews about how well they worked.

Then I came a cross the STC-1000+ thread started by alphaomega. When I saw how inexpensive the STC-1000 was, I decided right then and there that it was time to get going on this project.

The STC-1000+ project is downright amazing. I didn't get into that with mine (yet), but plan to in the future. You do not need to get into the electronics aspect if you just want simple temp control!

I used to fiddle around with electronics (a long time ago) but haven't had much free time in recent years with the garage/fabrication business. Now I have a bit more time and this post convinced me to start dabbling again.

I'm in Canada, so a lot of what I read on forums is a bit different, especially with respect to sourcing "the goods". On a Friday, I ordered an STC-1000 from Amazon.ca (which as I understand it, uses a different distribution network than the US amazon.com does.) I received it on Monday. (Lightening fast shipping.)

Here are some pics from when I received the unit:

Opened it up to check for compatibility with the STC-1000+ project:

I went to the local electronics store and picked up a project box I felt would fit the project best. I came a cross this one from Hammon Canada.

Components:

Next I modeled the box and the components to try different ideas for a clean look. I guess I went a little nuts with the details. (ADD / hyperfocus)

STC-1000:

Then I set out to build it.

Hope this might help others looking for ideas on how to set theirs up. I welcome all questions!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)