timdsmith72

Well-Known Member

Apologies up front for my writing style. I sort of bounce all over the place like a gerbil on speed.

Code has been uploaded to GIT.

https://github.com/timdsmith72/tempControl

Parts needed:

Waterproof DS18B20 Digital temperature sensor

Link: http://www.adafruit.com/products/381

RGB LCD Shield Kit w/ 16x2 Character Display

Link: https://www.adafruit.com/products/714

Ethernet Shield with Wiznet W5100 Ethernet Chip

Link: http://dx.com/p/ethernet-shield-with-wiznet-w5100-ethernet-chip-tf-slot-118061?tc=USD&gclid=CKz1-J3J77wCFajm7AodQHAA5Q#.UxDlmdysMpE

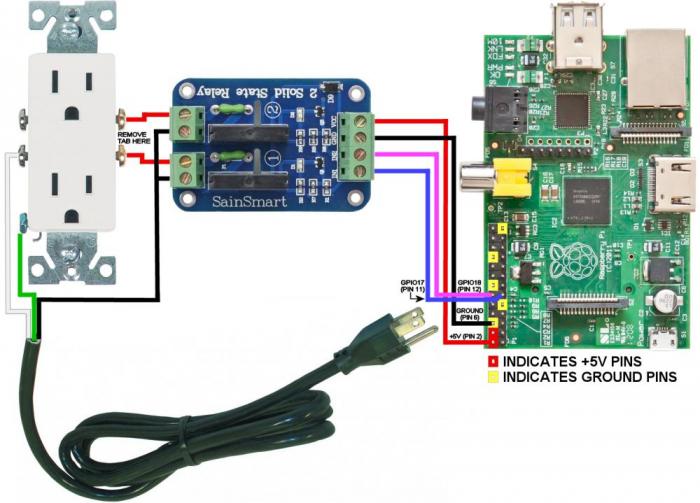

SainSmart 2 channel relay module

Link: http://www.amazon.com/SainSmart-2-CH-2-Channel-Relay-Module/dp/B0057OC6D8/ref=sr_1_1?s=electronics&ie=UTF8&qid=1393622113&sr=1-1&keywords=sainsmart+2+channel+relay

Of course, you don't have to use that particular relay module. That's just the one I chose.

Of course the Arduino Uno board

Link: http://www.mcmelectronics.com/product/83-13129

Looks like it's on backorder from MCM. But you can get it from any number of places. Even Radio Shack tends to have them in stock.

Power supply for your arduino

http://www.adafruit.com/products/63

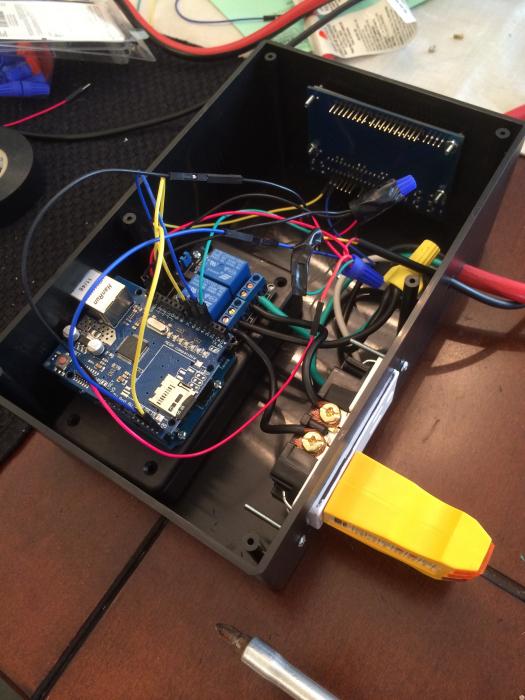

You'll also need some jumper wires and a nice heavy extension cord. 14AWG at least.

I think that's about it for the parts list. I also have an enclosure to mount the whole shebang in. But I reckon that's up to whatever you prefer.

So I have an STC-1000 temperature controller and I love it! It works great! But I can't tell you how many times I've gone to work and remembered just as I pulled into the parking lot, Dangit!! I meant to change the temperature before I left. For...Whatever reason. Step temperature changes, cold crashing, etc...

So I got to thinking, man it sure would be nice if I could change the temperature remotely. That's how this idea was born.

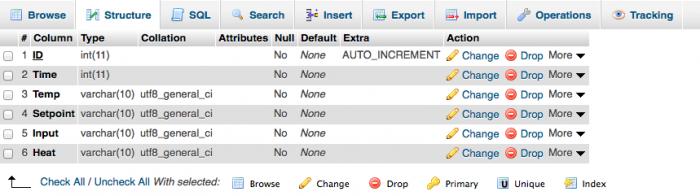

For this project, I'm using a MySQL database for to contain data for the graph. It also contains the desired set temperature which the Arduino queries at a set interval.

The database can be anywhere you want it, really. I have mine on a Raspberry Pi in my office. The Raspberry Pi also serves up the web page that displays the graph and has an entry box for changing the set temperature.

I'm using PHP to update the database. I suppose you could use whatever you're comfortable with.

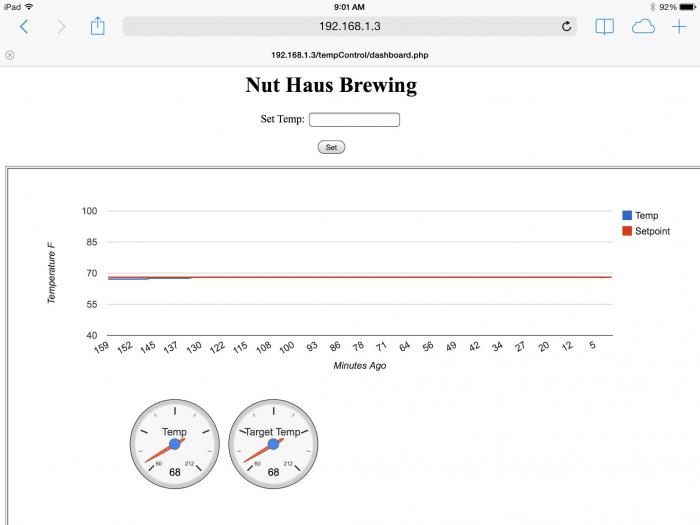

Here's what the graph looks like with the set temp box. This was taken before any code for the relays was written so it was just monitoring room temperature. But you get the idea of what it looks like.

Edited to add parts list

More posts to come as I get time to add them.

(Continued....)

Code has been uploaded to GIT.

https://github.com/timdsmith72/tempControl

Parts needed:

Waterproof DS18B20 Digital temperature sensor

Link: http://www.adafruit.com/products/381

RGB LCD Shield Kit w/ 16x2 Character Display

Link: https://www.adafruit.com/products/714

Ethernet Shield with Wiznet W5100 Ethernet Chip

Link: http://dx.com/p/ethernet-shield-with-wiznet-w5100-ethernet-chip-tf-slot-118061?tc=USD&gclid=CKz1-J3J77wCFajm7AodQHAA5Q#.UxDlmdysMpE

SainSmart 2 channel relay module

Link: http://www.amazon.com/SainSmart-2-CH-2-Channel-Relay-Module/dp/B0057OC6D8/ref=sr_1_1?s=electronics&ie=UTF8&qid=1393622113&sr=1-1&keywords=sainsmart+2+channel+relay

Of course, you don't have to use that particular relay module. That's just the one I chose.

Of course the Arduino Uno board

Link: http://www.mcmelectronics.com/product/83-13129

Looks like it's on backorder from MCM. But you can get it from any number of places. Even Radio Shack tends to have them in stock.

Power supply for your arduino

http://www.adafruit.com/products/63

You'll also need some jumper wires and a nice heavy extension cord. 14AWG at least.

I think that's about it for the parts list. I also have an enclosure to mount the whole shebang in. But I reckon that's up to whatever you prefer.

So I have an STC-1000 temperature controller and I love it! It works great! But I can't tell you how many times I've gone to work and remembered just as I pulled into the parking lot, Dangit!! I meant to change the temperature before I left. For...Whatever reason. Step temperature changes, cold crashing, etc...

So I got to thinking, man it sure would be nice if I could change the temperature remotely. That's how this idea was born.

For this project, I'm using a MySQL database for to contain data for the graph. It also contains the desired set temperature which the Arduino queries at a set interval.

The database can be anywhere you want it, really. I have mine on a Raspberry Pi in my office. The Raspberry Pi also serves up the web page that displays the graph and has an entry box for changing the set temperature.

I'm using PHP to update the database. I suppose you could use whatever you're comfortable with.

Here's what the graph looks like with the set temp box. This was taken before any code for the relays was written so it was just monitoring room temperature. But you get the idea of what it looks like.

Edited to add parts list

More posts to come as I get time to add them.

(Continued....)

Last edited by a moderator: