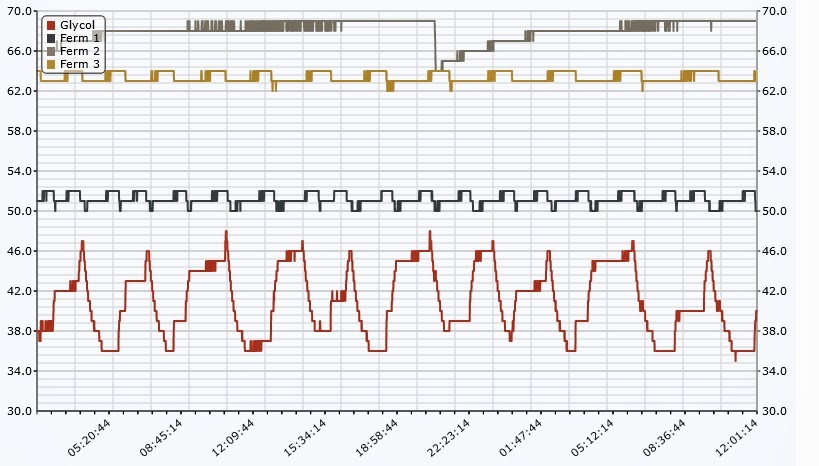

I suppose you could do it with 4 STC-1000's, but at that point you're saving ~$80 on the cost of the BCS-460, which would be offset by the extra 3 pumps you'd need to buy. You'd also lose the ability to automate lagering schedules, graph temps over time, and a web interface.

You'd have to change up the plumbing too. There wouldn't be a need for the motorized ball valves, but that was ~$120 of the entire cost of the project. So, not a gigantic deal.

Also, if anyone plans on building one in the future, don't get solenoid valves. Make sure you get motorized ball valves. Solenoids have really small openings for flow. So, all you need is one small piece of ice circulating in the system to stop glycol flow to your fermenter. MBVs are $15 more, but worth it for the added safety. It's also handy to get the MBVs with position indicators on them so you can glance and see which fermenter is operating at any given time.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)