What are you studying I grad school?

I'm going for an MBA.

What are you studying I grad school?

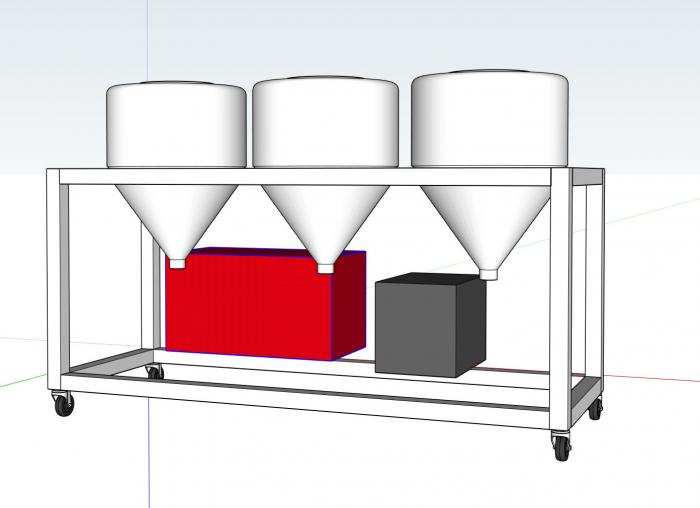

I just scribbled out the rough draft for doing the stand in metal with 22" squares for top frame, and flush welded plates with 18.8" holes with reinforced bracket below the plates supporting the corners. The bottom frame is going to be same length, but wider by about 8" off the back where I will rest the cooler and AC unit.

I'm going to do it out of aluminum, and then sandwich on top a single piece of diamond plate or maybe even thin stainless.

Going to start in September to coincide with q3 bonus.

Can you tell me, because its hard to see, what kind of clearance there is for putting a cooler off set on the back side, half on the 8" extender I was talking about, and half on the side encroaching upon the conical base? That's going to be the hardest to plan. I might add a couple inches to the overall height to get some margin here.

Anybody know a cheapo poor mans CAD type software that's easy to use?

TD

packet said:Are you thinking about putting the cooler to the right of the conicals? You could move the conicals closer together to save yourself some space and you might gain a foot or so without encroaching on the space below the conicals. A lot of my spacing was due to the thickness of 2x4s. If you're going with aluminum, you have a lot more space to place with.

Double check your conicals for the hole size though. I remember mine being 18.5-18.6" across.

As for cheap CAD, I like Sketchup. It's certainly not AutoCAD, but it gets the job done for DIY stuff.

Ill check into that. How in the heck do you measure the hole size? Measure circumference and then calculate? How true to round were your conicals or is that not a concern?

I was thinking about putting the cooler behind the conicals, since the cone part only occupies a portion of the space below the tabletop I thought if I made the base of the cart wider, or deeper rather, front to back, that I could make a small shelf for the cooler and AC unit combined. Planning to mount the enclosure to either right or left side of the cart, possibly below the rail, flush, but depends on the wiring and such. First I need the cart though.

Planning to use two inch square aluminum tubing for the cart frame. I want something strong but I don't want to use steel due to weight and cost.

Ill post up my sketch up as soon as I make one. Big concern I have is the feasibility of cramming the cooler and AC onto the bottom frame. I don't want to make the cart any bigger than it needs to be. Are the 22" squares the smallest size for the conicals, hate to use an odd number, and 20" seems it'd be tedious.

TD

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

One thing I am not sure about is positioning of the AC and the cooler and if they could be stacked with cooler above and AC below. I don't imagine there is a lot of flex to the coils. I suppose if I really want to, I could get an HVAC guy to customize the coil for repositioning or whatever. Had a guy repair my old kegerator when I hit a line drilling the side. He fixed the hole and added a refill fitting. Reasonable cost. That might offer some flexibility, but with added cost.

TD

I'm sure there is a 5 gal bucket in the 3D models. I'll check on that. I can always inch the cooler/AC over a bit. I'm thinking I might need to counterweight the front of the frame to balance out the weight.

Just a quick note on starting a process automatically with the BCS, there is a setting to start any process when the BCS is powered up. This is how I had my fermenter setup running a chest freezer. I believe the setting is hidden away under the system settings area.

packet said:Just extend the frame however far back you need to fit the chiller under it. This also means you won't need the backsplash for the plumbing as it'll fit in the extra space.

Are you able to get the lines cold enough to Cold Crash your beer if you wanted to in the fermentor?

packet said:That's what I normally do for ales. After it's done fermenting, drop the temp to ~40 degrees. Come back a day later, open the racking valve until it starts running clear and then keg the beer.

This keeps the bulk of the yeast out of the keg and I normally don't bother with gelatin anymore. Whirlfloc and cold crashing prior to kegging keeps the beer pretty clear.

Lately I've been lagering in the conicals too. I dump off the trub, drop the temp, and then come back a few weeks later once I have free space in the kegerator. Works great.

By the way, how low can you get the temps in this manner? What was the highest temp of hot wort you can pump into the conicals from the brew pot? Seems I recall 140°F?

packet said:I use a counterflow chiller from morebeer. In the summer, tap water is in the low 70s here. I generally can get the wort in the low 80s with it, which the glycol will take down to 45 for pitching lagers or low 60s for ales. In the winter, the wort will be in the low 60s before it gets to the conicals anyways.

What I'd really like to find is a large plate chiller that I can take apart and clean. Pretty much this, but with a smaller price tag:

https://brewmagic.com/products/components/plate-pro-sanitary-plate-heat-exchanger

Going to stick with the therminator and maybe I can clean it out for better performance.

packet said:I'd probably throw it in an oven for a bit to kill off whatever may be in there, let it cool down, and then circulate PBW through it the opposite direction of wort flow for an hour or two. Should clean pretty much everything out of it.

I'm not getting any infections, but rather poor cooling performance. I think I need to provide some restriction on the outlet side to ensure full contact with all of the plates. JB says recirculate hot PBW for 1 hour in each direction. Haven't had a chance to try that yet.

TD

No. I restrict flow at pump outlet. I worry that the lack of back pressure results in suboptimal or incomplete contact with all plate surfaces. I'm adding a ball valve to restrict the flow.

Question about the bcs used for this system. Can you program it to drop or rise 1° per day if you wanted or would you need to make those adjustments manually each day?

Packet, I have a few window AC units lying around. I'm pretty sure they are much bigger than 5k BTU. At the time (6 or 7 years ago) they were the biggest units you could get that still ran off 120v.

Do you think a glycol system could be arranged to cool boiling wort to pitching temperature quickly? How long is it taking you to drop yours from 80 to 60 in the conicals?

How long does it take to get your glycol system from ambient down to operating temp?

Just wondering if I could build a glycol system and run the chilled glycol through my immersion chiller. It would keep me from having to buy ice and waste so much water.

Also, do you expect the glycol/water solution to remain pure over time or is it something mold will take to?

Thanks. I know this is a divergence from the original (awesome) thread. I can create a new thread if needed.