johnwpowell

Well-Known Member

- Joined

- Dec 27, 2016

- Messages

- 261

- Reaction score

- 71

I haven't seen a lot of DIYs on chugger pump switches short of a full electric brewery control panel. Plugging and unplugging the pumps is a pain--they should be designed with an inline switch. Here's how I created a switchbox for my 2 chugger pumps.

Parts List

Tools List

Instructions

Parts List

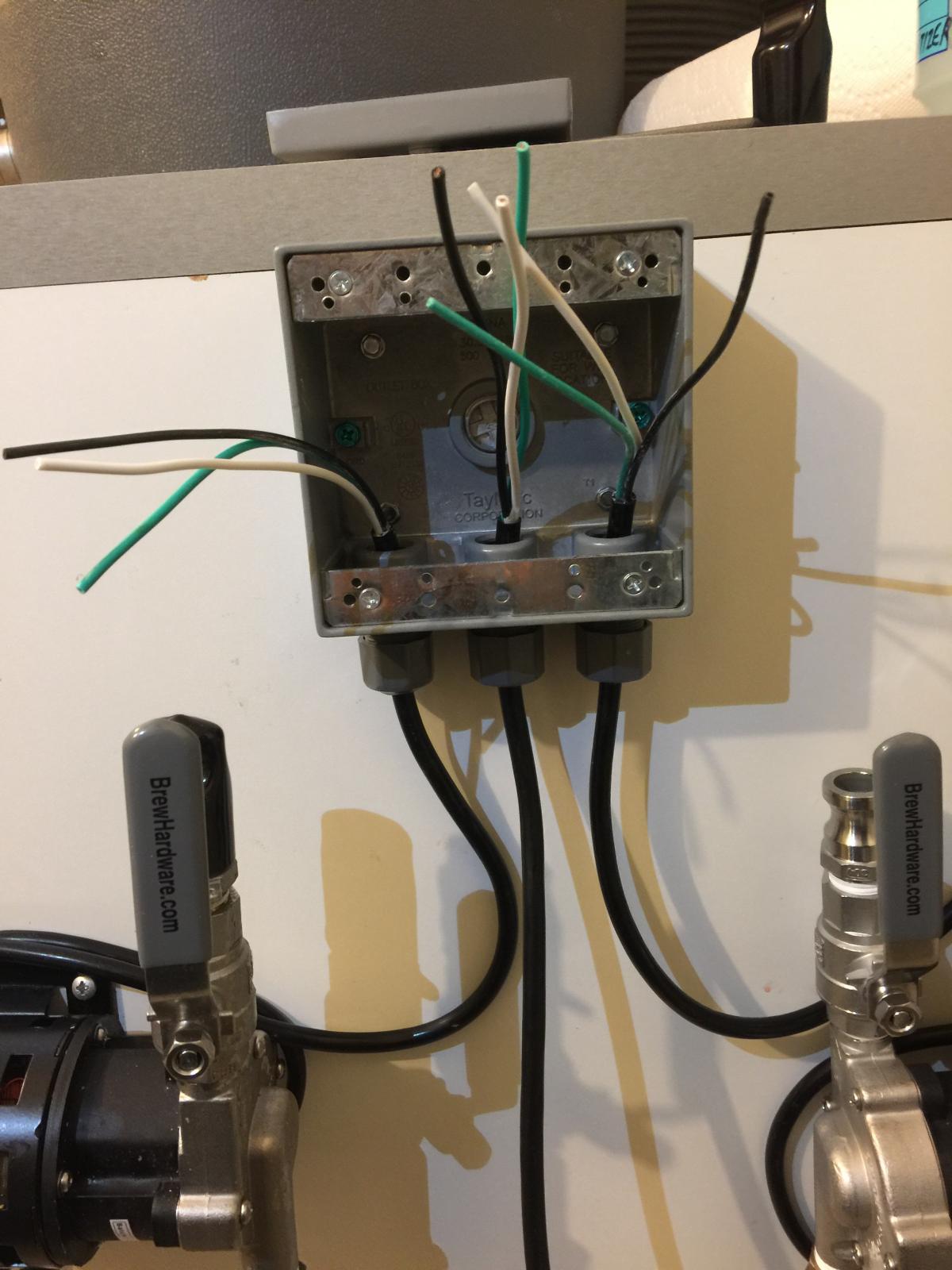

- Taymac DB750S 7-Inch by 1/2-Inch Holes 2-Gang Weatherproof Outlet Box

- Taymac TC221S Weatherproof Toggle Cover, 2-Gang, Vertical Device Mount, Two Single Pole Switches, Gray

- Stanley 33089 Grounded Outdoor Extension Power Cord, 8-Feet, Black (your length needs may vary)

- 3 Arlington LPCG50-1 Low-Profile Strain Relief Cord Connector, 1/2 Inch

- Closed end splice connectors

- Spade connectors

Tools List

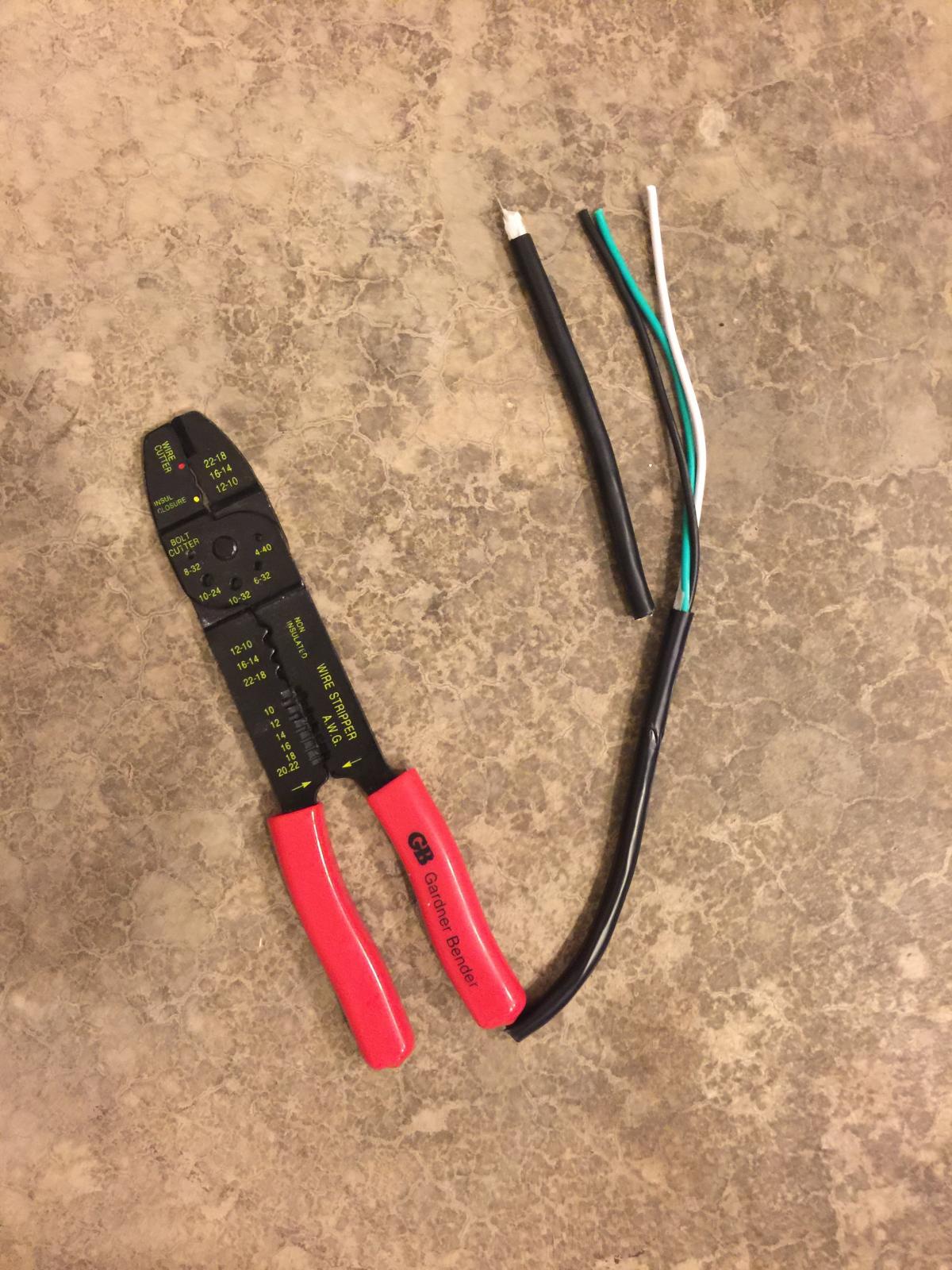

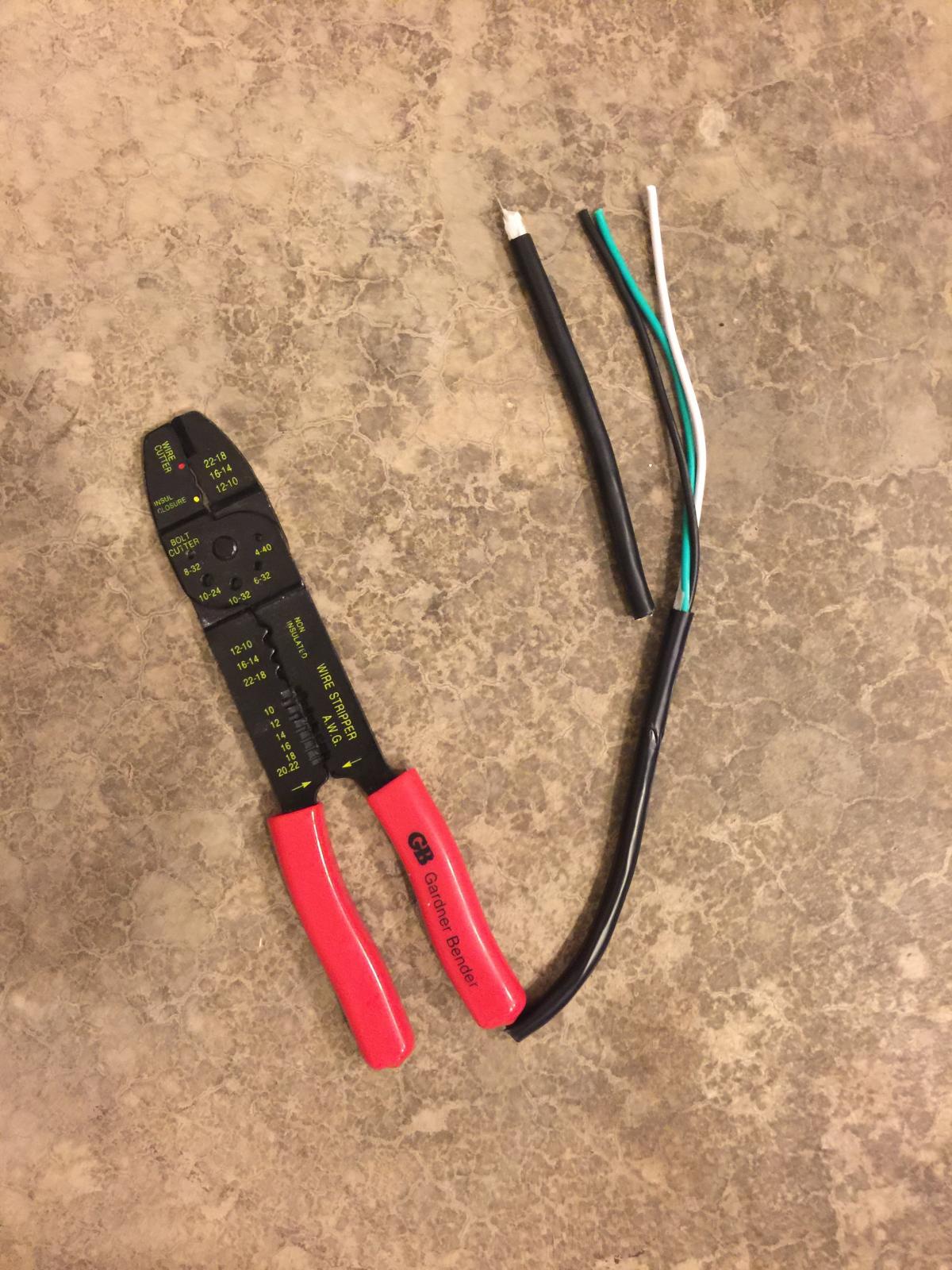

- Wire cutter/stripper/crimper

- Drill and drill bits

Instructions

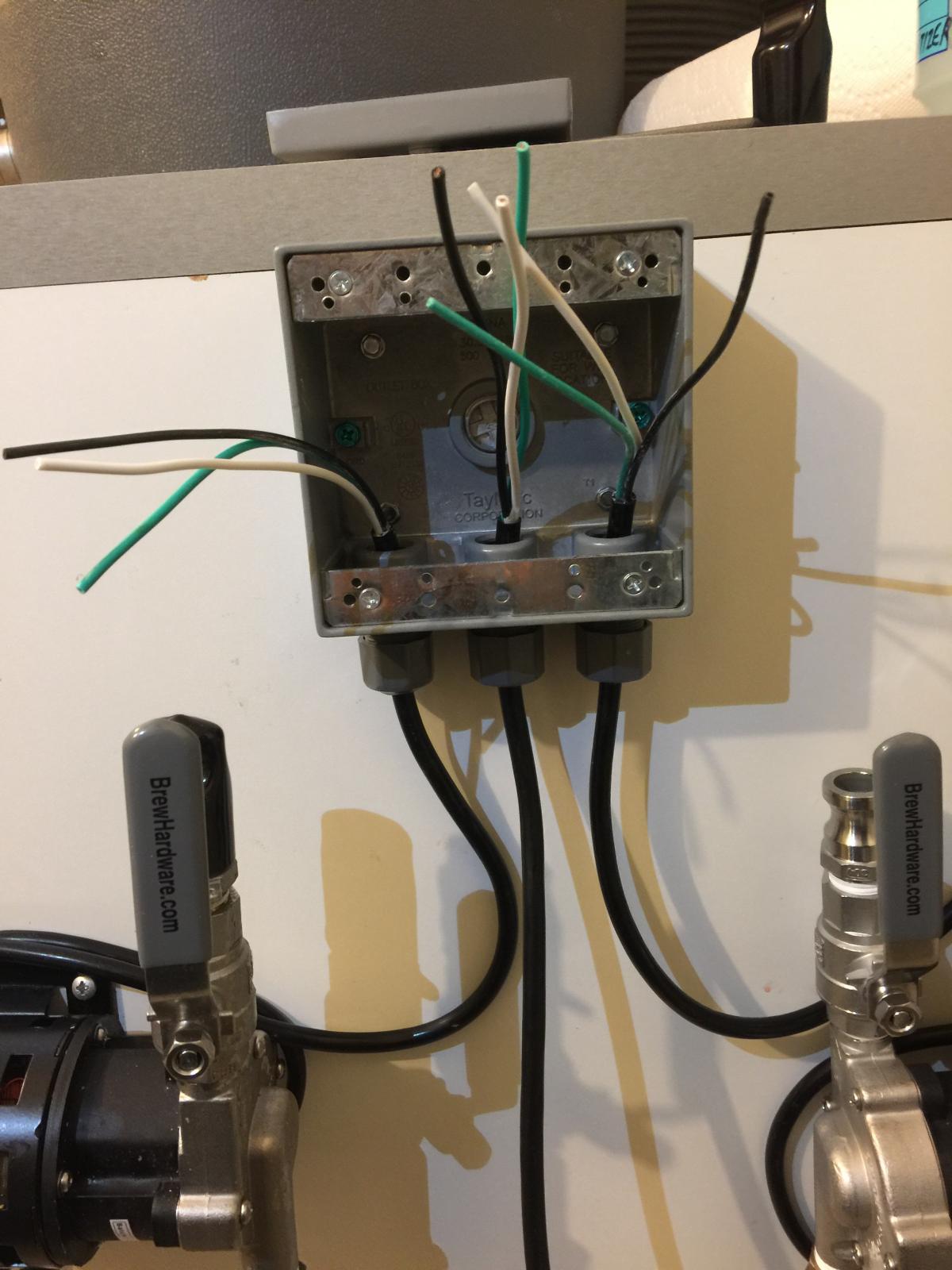

- Plug the 3 unused holes at the top and the 1 unused hole at the back of the enclosure with the supplied hole closure plugs

- Drill holes to mount the enclosure. I drilled 4 holes at the back to screw to my brewing table. Use a center punch to mark and a metal drill bit slightly larger than the screws you plan to use

- Mount the enclosure using screws/hardware of your choice

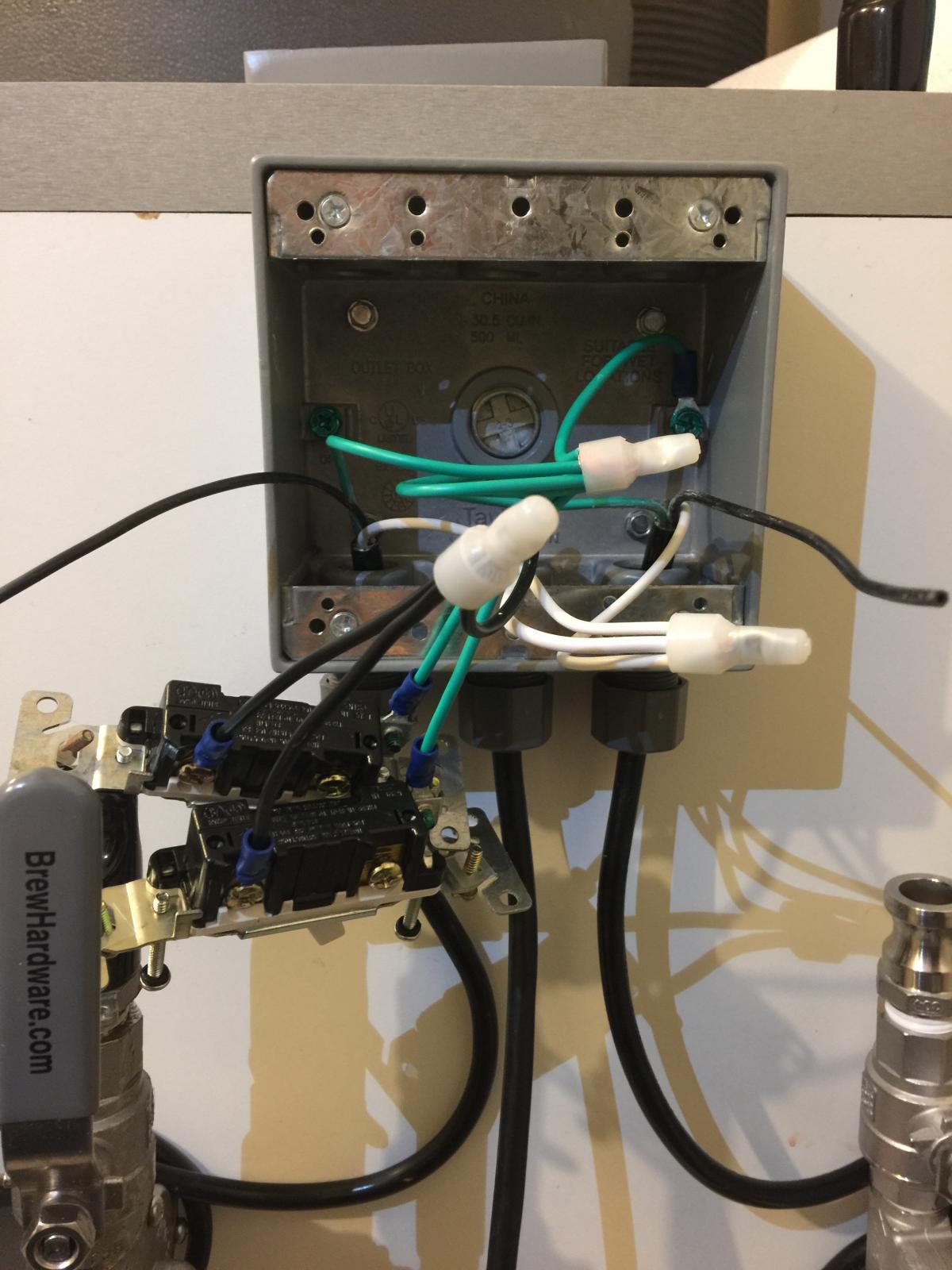

- Remove and discard the metal nuts from the waterproof cord connectors and thread into the 3 bottom holes of the enclosure

- Cut the female plug off the extension cord

- Cut 1' off the extension cord, carefully remove the outer jacket and sit the wires aside (you will use the wire for jumpers in the next steps)

- Carefully strip 6 inches of the extension cord outer jacket to expose the 3 wires

- Feed the extension cord wire into the middle connector and tighten

- Cut the male plugs off the chugger pumps, carefully strip 6 inches of the outer jacket and feed into the left and right connectors respectively and tighten

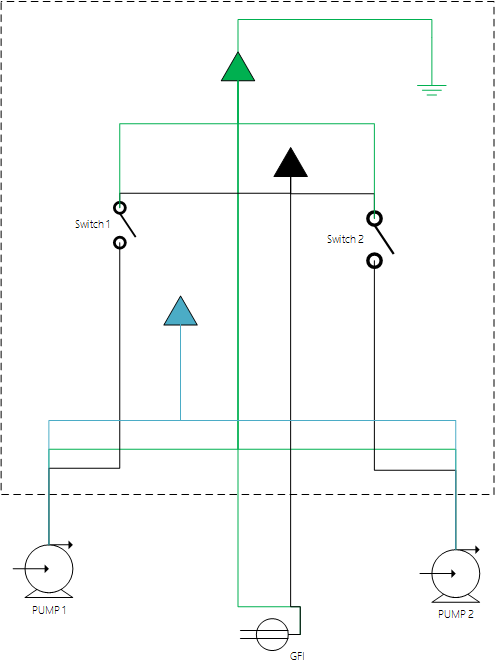

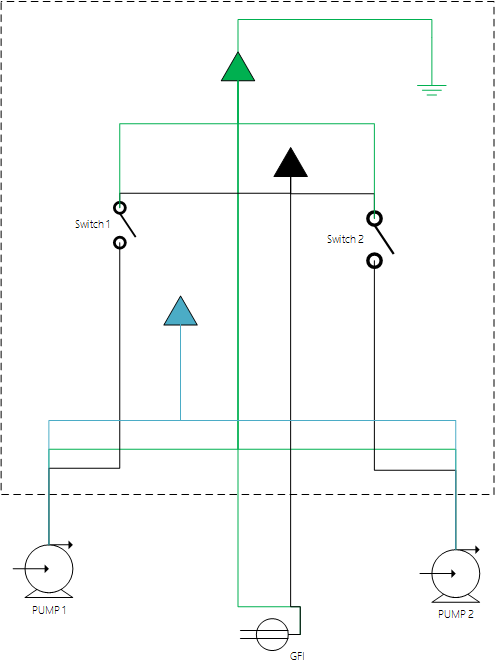

- Use the diagram below to wire the switch. Note I used blue to indicate the neutral (white) wire since the diagram background is white

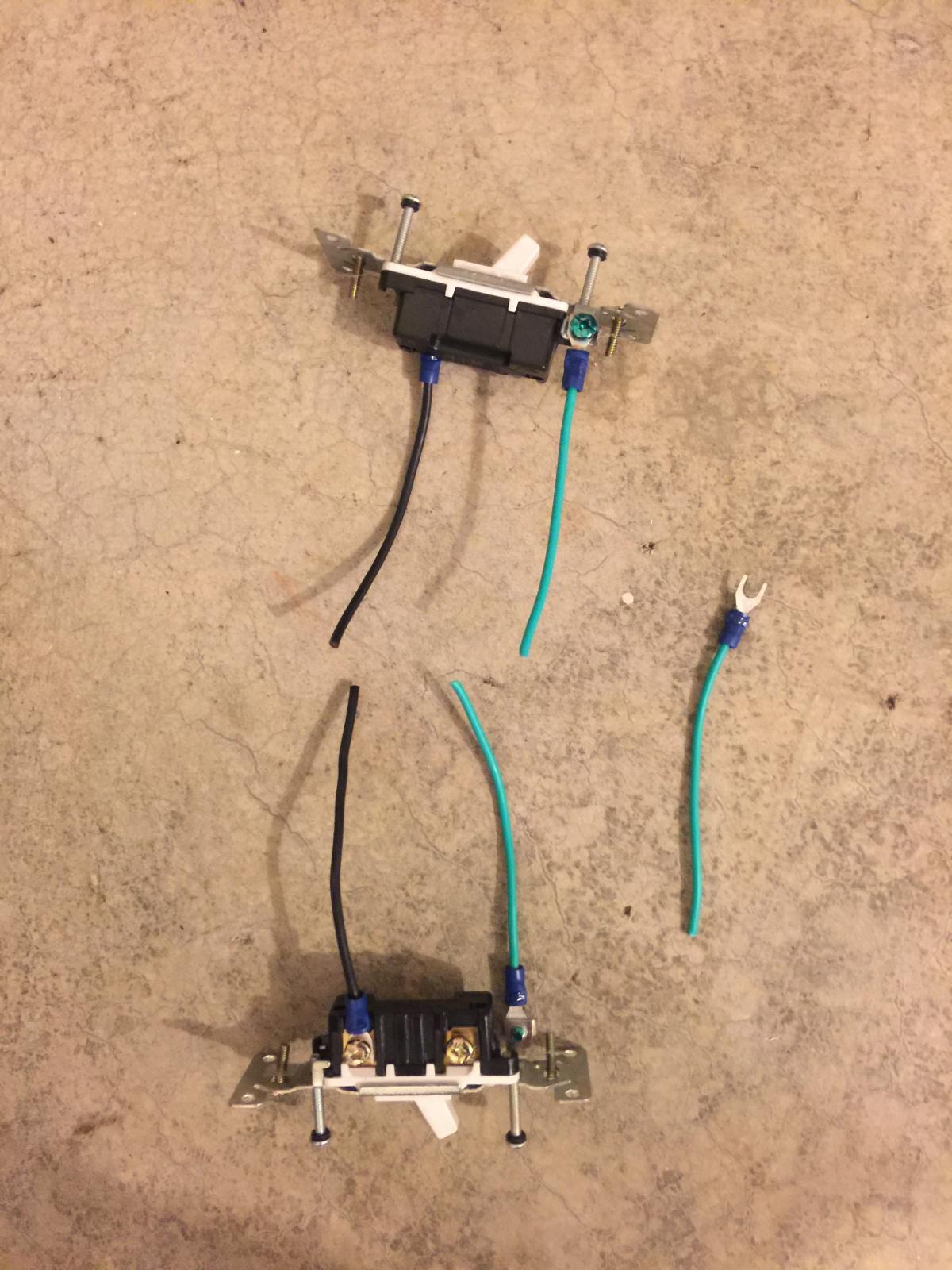

- Cut three 4" length green jumper wires from the 1' extension cord

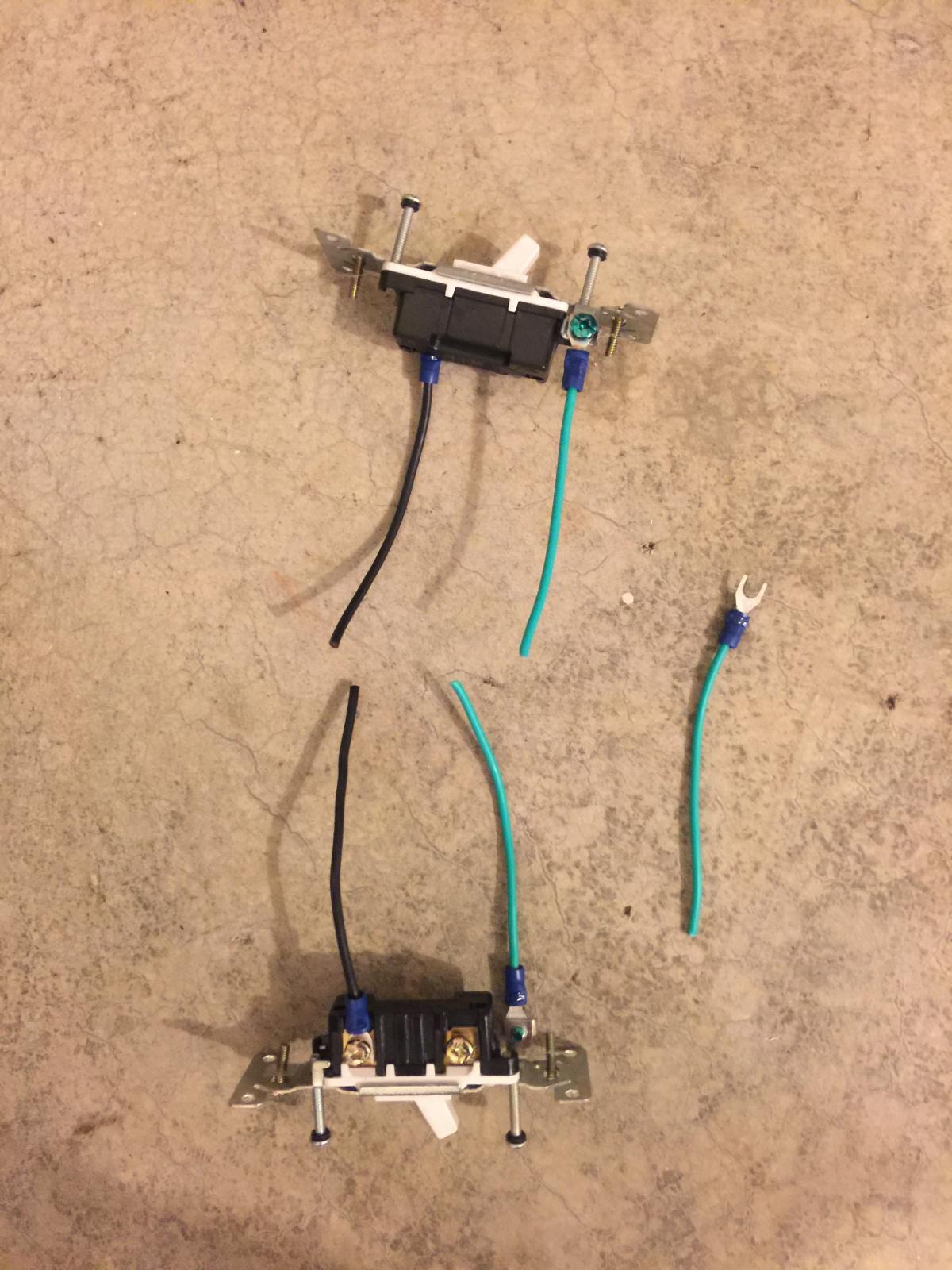

- Strip 1/2" of insulation from each end of the 3 green jumper wires and crimp a spade connector on one end

- Strip 1/2" of insulation from each of the 3 green wires from the extension cord and pumps together along with the 3 jumper wires and crimp in a closed end splice connector

- Attach one green jumper wire to the green screw in the enclosure

- Attach the other green jumper wires to the green screws on each of the switches

- Strip 1/2" of insulation and twist the 3 white wires together and crimp with a closed end splice connector

- Cut two 4" lengths of black wire from the 1' extension

- Strip 1/2" of insulation from each end of the jumper wires and attach a spade connector to one end

- Strip 1/2" of insulation and twist the 3 black wires from the incoming extension cord along with the 2 jumper wires and crimp in a closed end splice connector

- Attach the black jumper wires to the top of each switch

- Strip 1/2" of insulation from the black wire from each of the chugger pumps and crimp a spade connector on it

- Connect the black wires from the chugger pumps to the bottom of each switch

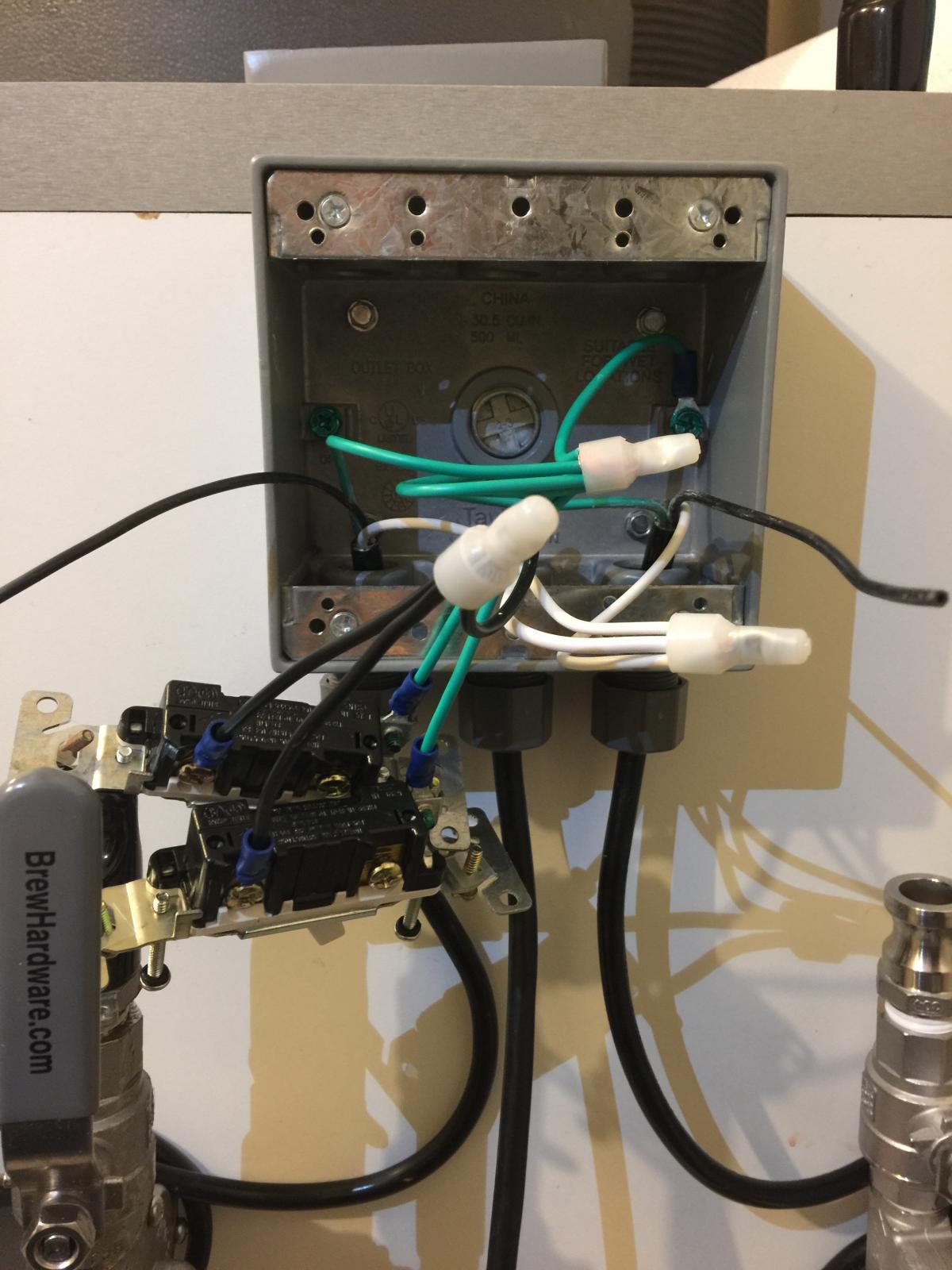

- Install switches in box being careful to push wires in so they are not too crowded

- Install the gasket (it will help you to know when the screw holes are lined up properly)

- Install the cover (note: you don't need the horseshoe connectors that come in the kit)

- Ensure the switches are in the off position

- Prime the pumps

- Plug into a GFCI outlet and test

Last edited by a moderator:

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)