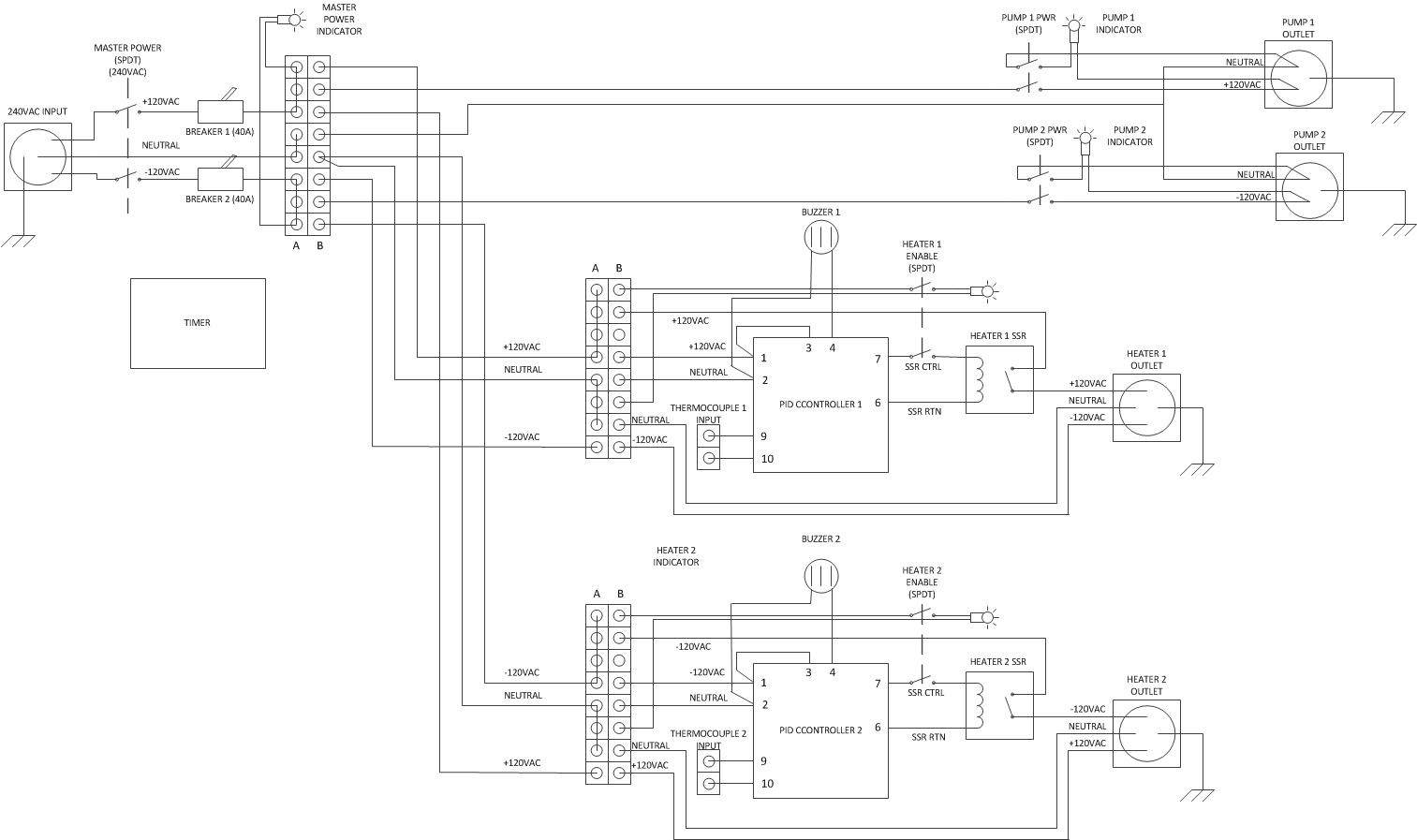

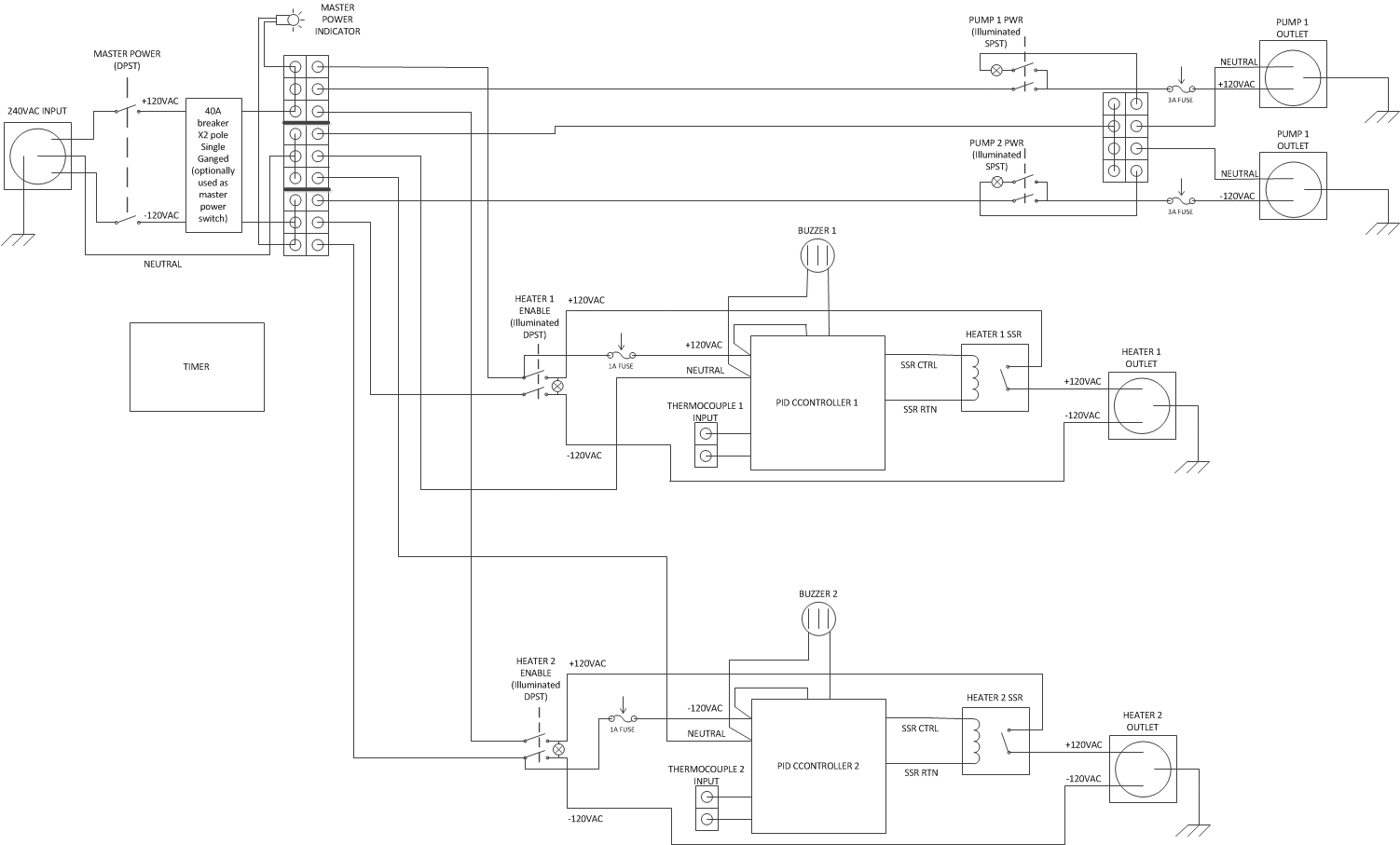

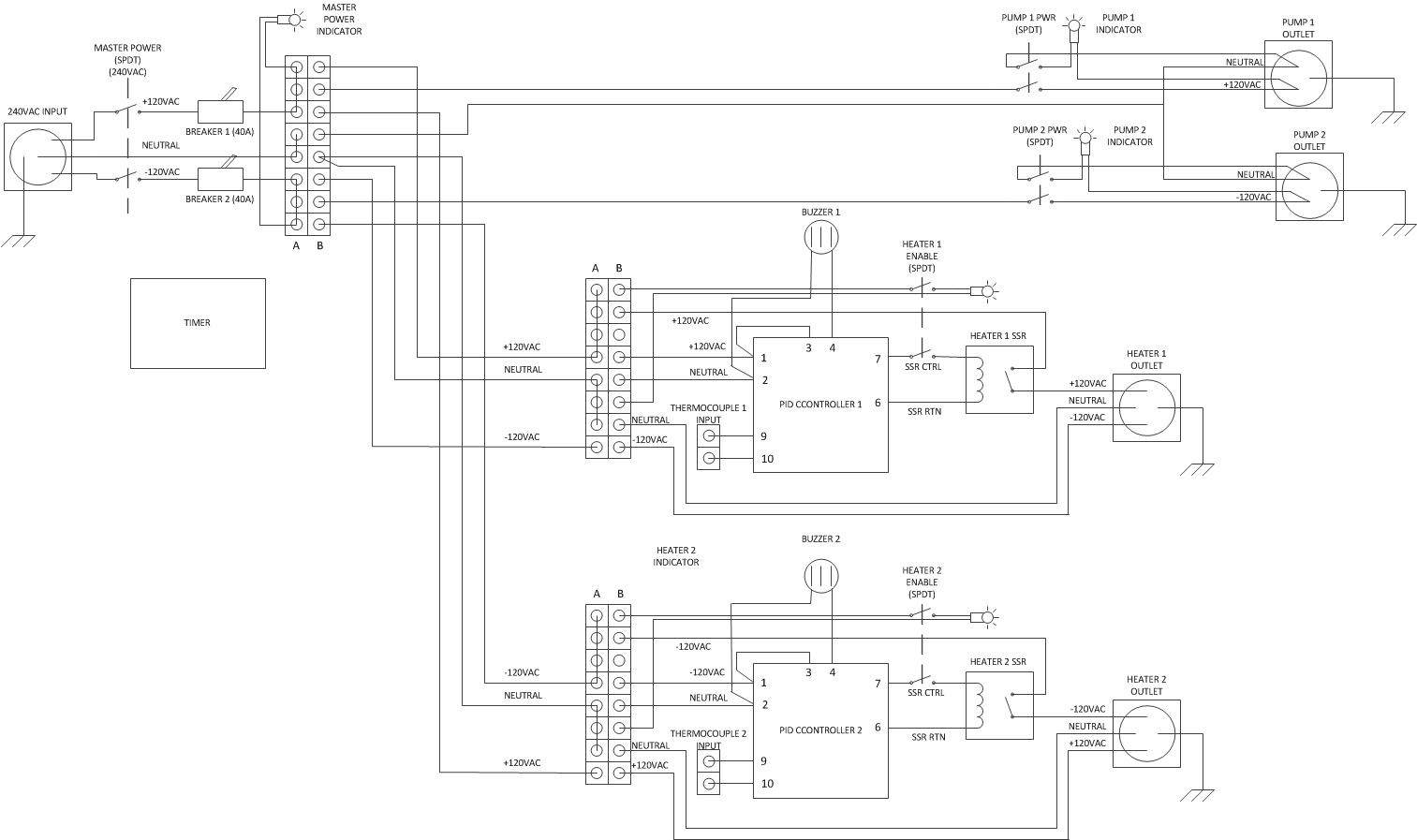

My friend and I are building a brewing controller and we figured we post the electrical layout on here to see what people think. If anyone has suggestions on what we might be missing or maybe an issue you see, feel free to let me know. Also we are still looking around for a housing for the controller, if anyone has any suggestions on that too.

I am mainly going to use this to control a rims system with the option to control a HLT heater in the future. Both will be 240V while the 2 pumps I have are 120V. I will be plugging this into my range outlet which is (2) 40a circuits.

Decided to go with the lighted button combo, green and red.

http://www.digikey.com/product-detail/en/cherry/WRG32F2FBGLN/CH791-ND/446057

Took me a little to find a PID that came in F, but I found this one.

http://www.thermomart.com/mini-controller

I was trying to save some money by making it myself so some of the items I was really searching for the lowest priced decent quality items. Like I said I am open to suggestions on any of this stuff. Thanks guys.

I am mainly going to use this to control a rims system with the option to control a HLT heater in the future. Both will be 240V while the 2 pumps I have are 120V. I will be plugging this into my range outlet which is (2) 40a circuits.

Decided to go with the lighted button combo, green and red.

http://www.digikey.com/product-detail/en/cherry/WRG32F2FBGLN/CH791-ND/446057

Took me a little to find a PID that came in F, but I found this one.

http://www.thermomart.com/mini-controller

I was trying to save some money by making it myself so some of the items I was really searching for the lowest priced decent quality items. Like I said I am open to suggestions on any of this stuff. Thanks guys.