I've been holding off getting into this hobby for a long time. I've recently moved out of the city and the cramped apartment that came with it and into a home I own in the boonies. It's time to start brewing and I'm looking to skip the extract and lower end all in one systems and piece together a versatile grain to keezer system.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Diving in head first

- Thread starter ninkwood

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Mar 31, 2020

- Messages

- 1,284

- Reaction score

- 2,224

into the deep end at that!

Good luck..and remember to have fun! Lots of resources and knowledge on the forum, hope you enjoy reading! Looking forward to hearing about your journey.

Good luck..and remember to have fun! Lots of resources and knowledge on the forum, hope you enjoy reading! Looking forward to hearing about your journey.

Velnerj

Simul justus et potator

Yes, go for it! If you are passionate about it why not jump head first? I went all grain right away and never looked back.

Just a FYI I started with a piecemeal diy brewery which consisted of mash tun cooler big boil kettle and propane burner. Eventually Graduated to an all in one system. Although I did learn a lot by cutting my teeth on a rustic system. I will never go back after using my all in one system.it makes everything so much easier especially clean up. Don't count those out immediately.

Just a FYI I started with a piecemeal diy brewery which consisted of mash tun cooler big boil kettle and propane burner. Eventually Graduated to an all in one system. Although I did learn a lot by cutting my teeth on a rustic system. I will never go back after using my all in one system.it makes everything so much easier especially clean up. Don't count those out immediately.

ninkwood

Well-Known Member

I have a tonne of related hobbies such as bread and pizza. I've gone pretty far down the rabbit holes on both of those, and don't see much real payoff to spending lots of money on fancy ovens/equipment.

However beer is another story! I might be wise to start small and take it slow, but I know myself well enough that if I have full control over the process I'll enjoy it alot more.

I may pickup a used brewzilla or something similar if I find a used one cheap enough as I could always turn around and sell it again for about what I pay. But I think I'll start with the keezer and some brewery kegs. That way, I'll get a taste of the light at the end of the tunnel and a better idea if the juice is worth the squeeze!

Cheers!

However beer is another story! I might be wise to start small and take it slow, but I know myself well enough that if I have full control over the process I'll enjoy it alot more.

I may pickup a used brewzilla or something similar if I find a used one cheap enough as I could always turn around and sell it again for about what I pay. But I think I'll start with the keezer and some brewery kegs. That way, I'll get a taste of the light at the end of the tunnel and a better idea if the juice is worth the squeeze!

Cheers!

It's still wise to start simple (and small) to see if you like the process.

Using a large, 2-3 gallon kitchen pot you can brew all-grain beer on your stove.

Using a large, 2-3 gallon kitchen pot you can brew all-grain beer on your stove.

I went all in for all grain brewing from day one. Two months of reading everything I could, a lot from this forum, before I bought my first piece of equipment. Most will tell you to start with extract and move up from there, but if you are willing to do your homework, you can go all grain to start. I am 6 years and more than 100 brews in and have NEVER done an extract brew. Nothing wrong with brewing with extract but I enjoy the whole process. Everything form the water chemistry to milling my own grains to yeast ranching.

If you want to go all grain to start, DO YOUR HOMEWORK! and you will succeed.

If you want to go all grain to start, DO YOUR HOMEWORK! and you will succeed.

ninkwood

Well-Known Member

Great point, I never thought about it like this. I could do some small batches without much of an investment at all!It's still wise to start simple (and small) to see if you like the process.

Using a large, 2-3 gallon kitchen pot you can brew all-grain beer on your stove.

ninkwood

Well-Known Member

Yup, I feel you here. What I always do with these things is I spend a few months researching and watching, learning and living vicariously through other people. I basically push it to the point where I can't handle it anymore or I lose interest. It's a good way to test if the passion is there!

I've been watching a tonne of YouTube lately and I'm feeling the itch to get started!

I've been watching a tonne of YouTube lately and I'm feeling the itch to get started!

If you already have a 2 or 3 gallon kitchen pot or canning kettle, you can do your mash in there, sticking it inside a pre-warmed, but turned off oven. The temp should be kept between 145-155F during the hour-long mash. You can take a temp measurement of the mash after 20 minutes, and turning the oven on for a few minutes, if needed. Overheating (>158F) for longer than 10 minutes can start denaturing the enzymes, slowing down the conversion from starches to sugars.Great point, I never thought about it like this. I could do some small batches without much of an investment at all!

When done, strain the wort into another pot or (temporary) bucket.

Once you know brewing is for you, reading John Palmer's How to Brew, 4th Ed. will help understanding all the sub-processes involved in brewing.

Good, thorough sanitation of everything that touches your chilled wort or beer, is the very important!

ninkwood

Well-Known Member

Great idea! I've got a 24 qt and a 20qt stock pot that I could definitely use, and I've got a few kitchen thermometers and fine mesh strainers so I should be able to make something passable with my stove. The pots won't fit in my oven and I don't have anything in between these and something far too small. Might just have to keep the batch size down to 1-2 gallons. Good idea to use the oven though, and thanks for the book recommendation!If you already have a 2 or 3 gallon kitchen pot or canning kettle, you can do your mash in there, sticking it inside a pre-warmed, but turned off oven. The temp should be kept between 145-155F during the hour-long mash. You can take a temp measurement of the mash after 20 minutes, and turning the oven on for a few minutes, if needed. Overheating (>158F) for longer than 10 minutes can start denaturing the enzymes, slowing down the conversion from starches to sugars.

When done, strain the wort into another pot or (temporary) bucket.

Once you know brewing is for you, reading John Palmer's How to Brew, 4th Ed. will help understanding all the sub-processes involved in brewing.

Good, thorough sanitation of everything that touches your chilled wort or beer, is the very important!

I brew 4G batches with a 5G kettle plus a 5G bucket for a dunk sparge. Granted, I push my mash and/or pre-boil volumes to near spill over levels, but a 3G batch would be easy peasy.

Last edited:

Wrapping some insulation such as towels, (old) sleeping bag, moving blankets, etc. around the kettle's sides, bottom, and lid helps against heat loss during the mash.The pots won't fit in my oven and I don't have anything in between these and something far too small.

Make sure to remove the insulation before heating on your stove.

Size your batches to your fermentation vessels, filling them only 3/4 to 4/5 with wort. Leaving 1/5-1/4 of the fermenter's volume as headspace is good practice. Some yeasts are also more vigorous than others, especially when fermenting at higher temps.

That said, fermenting toward a yeast's lower end of her temp range is usually recommended, it makes better tasting beer. There are exceptions, such as Saison yeasts, and some Kveik yeasts, showing their character at the higher side of their temp range.

bellhp

Well-Known Member

I use an unmodified igloo cooler and a grain bag to mash . It's ridiculously easy . One of our members made this video and it's basically what I do ... got a 5 gal igloo and 20qt stock pot for my 5 gallon brews .

Edited... because I'm an idiot and forgot the link to Cascades brewer's video

Edited... because I'm an idiot and forgot the link to Cascades brewer's video

Last edited:

ninkwood

Well-Known Member

speaking of fermentation temps...Wrapping some insulation such as towels, (old) sleeping bag, moving blankets, etc. around the kettle's sides, bottom, and lid helps against heat loss during the mash.

Make sure to remove the insulation before heating on your stove.

Size your batches to your fermentation vessels, filling them only 3/4 to 4/5 with wort. Leaving 1/5-1/4 of the fermenter's volume as headspace is good practice. Some yeasts are also more vigorous than others, especially when fermenting at higher temps.

That said, fermenting toward a yeast's lower end of her temp range is usually recommended, it makes better tasting beer. There are exceptions, such as Saison yeasts, and some Kveik yeasts, showing their character at the higher side of their temp range.

other than using a chilling coil, a pump, and a temp controlled relay to run ice water from a cooler into the fermenter, is there any cost sensitive way to dial in fermentation temps?

I was thinking of building a Keezer first (use it with brewery kegs til I'm up and running) and dedicating some space to a water tank of refrigerated water, then running the lines to the fermenter. But I've been told this will not work...

ninkwood

Well-Known Member

wow that's a pretty good idea! I've read of a similar sous vide hack that uses a cooler and pre-heated water.I use an unmodified igloo cooler and a grain bag to mash . It's ridiculously easy . One of our members made this video and it's basically what I do ... got a 5 gal igloo and 20qt stock pot for my 5 gallon brews .

Velnerj

Simul justus et potator

Most homebrewers get a small fridge that fits their fermenter. They connect a temperature controller (I. E.i. Inkbird) to the fridge with the probe on the fermenter. This holds temperature very well. If you find a used fridge it can also be quite cheap.speaking of fermentation temps...

other than using a chilling coil, a pump, and a temp controlled relay to run ice water from a cooler into the fermenter, is there any cost sensitive way to dial in fermentation temps?

I was thinking of building a Keezer first (use it with brewery kegs til I'm up and running) and dedicating some space to a water tank of refrigerated water, then running the lines to the fermenter. But I've been told this will not work...

Another option is a swamp cooler. This involves getting a large container big enough to hold your fermenter along with some (ice) water. Placing your fermenter into the container with water and adding ice periodically. People also drape a wet t-shirt or towel over the fermenter with a fan to encourage cooler temps. It's cheap but requires some attention and is not as accurate with temps.

BrewnWKopperKat

ʘ‿ʘ

caution: slightly off topic

Currently on day 6 fermenting an 1.75 gal OG 85 strong ale using Nottingham.

Wort was 68° F ± 1 for all but one measurement (which came in at 70°). Water temperature was in the same range. Room temperature was 67° to 70°.

In the summer, I use chilled water (~ 42°) to lower the temperature of the water in 1° increments. The wort temperature follows along within a couple of hours. In the winter, the approach is different (start with water at 2° above desired fermentation temperature, then adjust with hot tap or chilled water).

For me, the closed chest cooler idea works well with small (2.5 gal or less) batches (I don't have equipment to try it with 5 gal batches).[closed chest cooler: ] It's cheap but requires some attention and is not as accurate with temps.

Currently on day 6 fermenting an 1.75 gal OG 85 strong ale using Nottingham.

Wort was 68° F ± 1 for all but one measurement (which came in at 70°). Water temperature was in the same range. Room temperature was 67° to 70°.

In the summer, I use chilled water (~ 42°) to lower the temperature of the water in 1° increments. The wort temperature follows along within a couple of hours. In the winter, the approach is different (start with water at 2° above desired fermentation temperature, then adjust with hot tap or chilled water).

Using an external fermentation chiller pumping cold liquids (propylene glycol usually) through a coil in the fermenter is not all that common among homebrewers, especially beginning ones.other than using a chilling coil, a pump, and a temp controlled relay to run ice water from a cooler into the fermenter, is there any cost sensitive way to dial in fermentation temps?

Swamp coolers, and dedicated temp controlled refrigerators/freezers using an "external" thermostat, as mentioned above, are more the norm, even with seasoned brewers.

bellhp

Well-Known Member

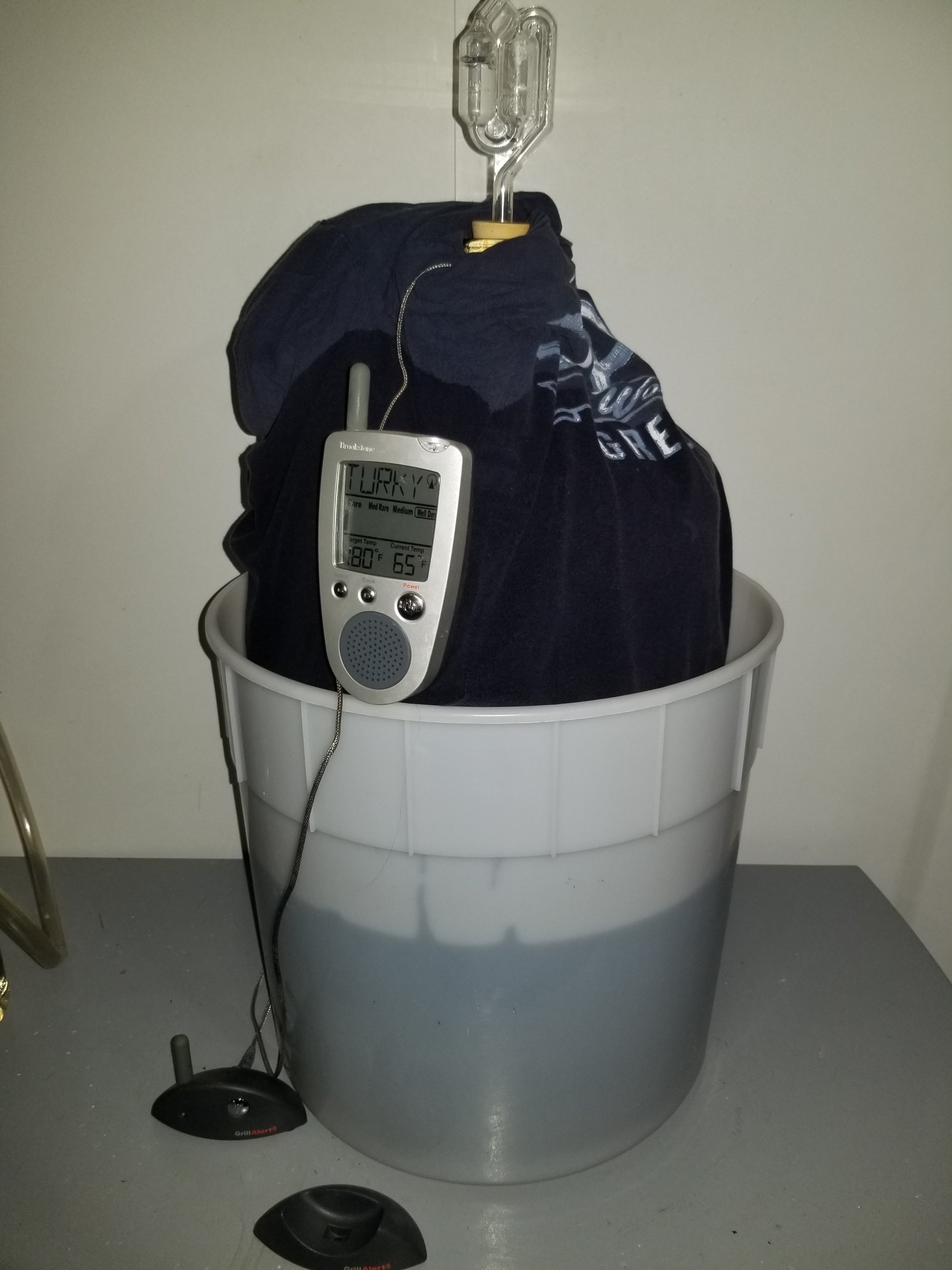

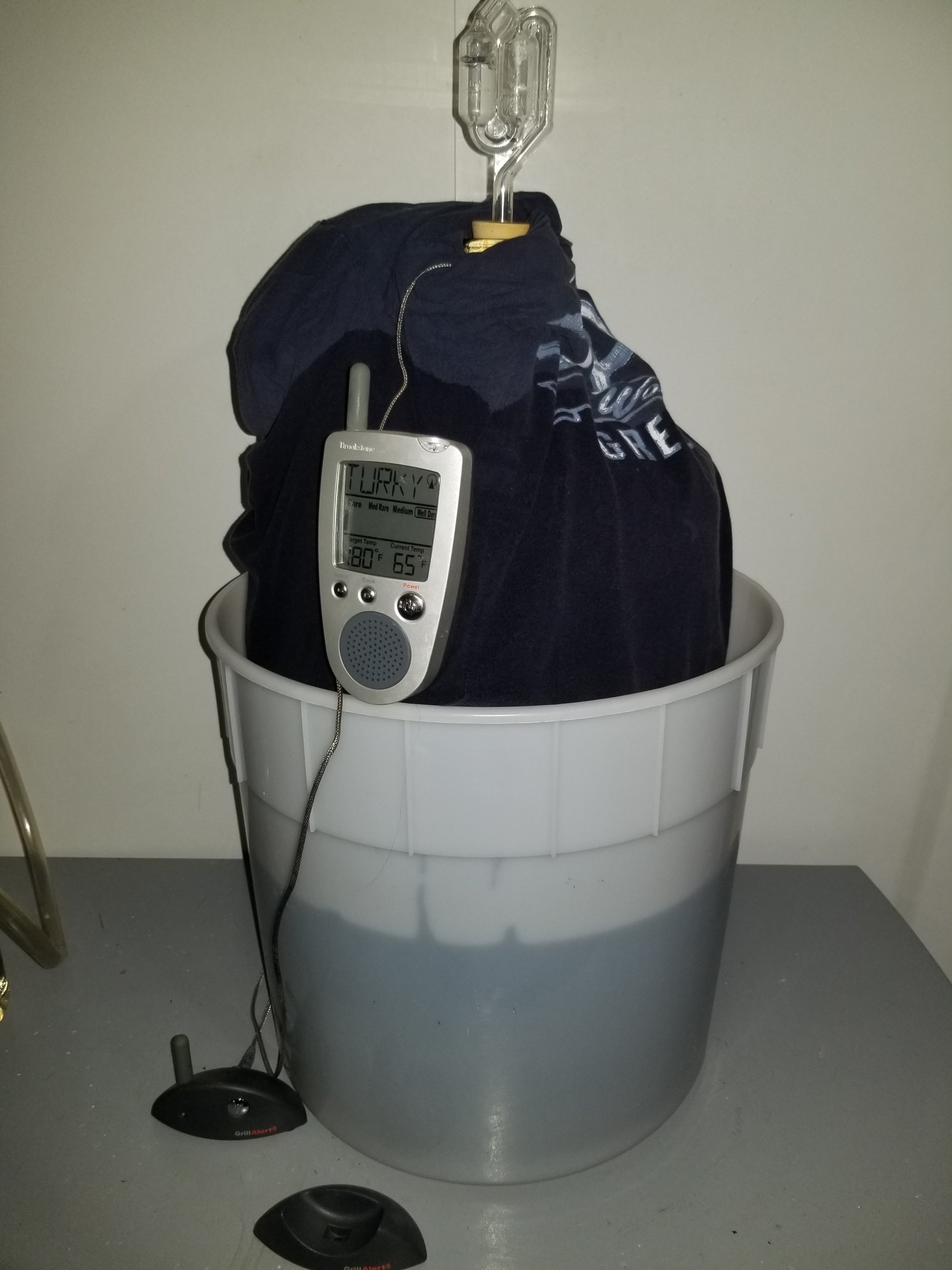

This is my swamp cooler setup on the Fig stout I'm fermenting now.

The thermometer is just a BBQ remote thermometer and it is outside of the carboy just to give me an idea as to the temp under the wet t-shirt. my house is usually 70-72 degrees F and the thermometer will read anywhere from 2 to 5 degrees cooler . Not fancy but it seems to work for me.

The thermometer is just a BBQ remote thermometer and it is outside of the carboy just to give me an idea as to the temp under the wet t-shirt. my house is usually 70-72 degrees F and the thermometer will read anywhere from 2 to 5 degrees cooler . Not fancy but it seems to work for me.

ninkwood

Well-Known Member

thanks guys! I think i'll end up going with the dedicated fridge/temp controller as it seems the cost will be about the same when you factor in the pump and chilling coil are nearly the cost of a used fridge. Now to convince the wife to let me keep it somewhere in the house...

- Joined

- Jan 3, 2020

- Messages

- 2,273

- Reaction score

- 2,357

As far as a fermentation chamber, I used to think a minifridge was a good deal vs a kegerator but if you can find a used kegerator it usually worth the added expense as they won't require much modification. If you can fit two corny kegs in it, which I think many do, also good because you could ferment in two kegs if you choose to. It can also serve as on deck cold storage if your keezer is full. A wine chiller is another option as it won't have the little freezer inside which can be difficult to alter.thanks guys! I think i'll end up going with the dedicated fridge/temp controller as it seems the cost will be about the same when you factor in the pump and chilling coil are nearly the cost of a used fridge. Now to convince the wife to let me keep it somewhere in the house...

Also, I will mention that if you have a room where the room temperature is about 70F or less most of the year, your temperature control for ales will involve mainly heating not cooling. If your location is current, I think that applies to you as I'm showing you are in Canada? Unless you want to jump into brewing lagers immediately as well, you may be better off with simply a heating mat and temperature controller. My basement is slightly too warm for ales in the summer and I am further south.

ninkwood

Well-Known Member

Some great points here! I've considered keg fermenting as I definitely plan to have kegs on hand, however for full flexibility I'm looking at the fermzilla conical as that would allow me to make additions without o2 exposure and clean the trub a bit easier than with a keg.As far as a fermentation chamber, I used to think a minifridge was a good deal vs a kegerator but if you can find a used kegerator it usually worth the added expense as they won't require much modification. If you can fit two corny kegs in it, which I think many do, also good because you could ferment in two kegs if you choose to. It can also serve as on deck cold storage if your keezer is full. A wine chiller is another option as it won't have the little freezer inside which can be difficult to alter.

Also, I will mention that if you have a room where the room temperature is about 70F or less most of the year, your temperature control for ales will involve mainly heating not cooling. If your location is current, I think that applies to you as I'm showing you are in Canada? Unless you want to jump into brewing lagers immediately as well, you may be better off with simply a heating mat and temperature controller. My basement is slightly too warm for ales in the summer and I am further south.

I certainly could require heat in addition to cold depending what and when I'm fermenting, but also where I decided to ferment in the house. I haven't mentioned the heating equation as I feel that's pretty self-explanatory, just purchase a heating mat/wrap and add it to the heat side of the temp controller. My original goal was to utilize the keezer for both keg storage/serving and for fermentation cooling. I'm moving away from that idea now and considering a separate fridge/freezer that fits the fermzilla.

All this is to say that I'm still in the planing and learning stage here and I will be for quite some time. There's alot you can learn without doing these days, and if a hobby is really going to stick I think it's worthwhile to prove it by soaking up all that can be prior to spending money. If I do jump into this, I'd like to go big - but not big enough for glycol.

Similar threads

- Replies

- 2

- Views

- 151

- Replies

- 7

- Views

- 774

- Replies

- 2

- Views

- 1K

- Replies

- 4

- Views

- 776

- Replies

- 7

- Views

- 391