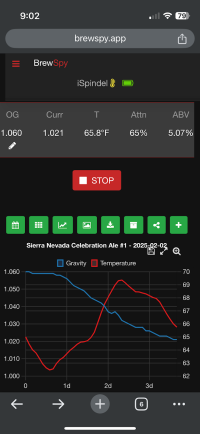

I am 4 days into fermentation with US-05 and it's been between 65F-70F for the past 3 days, is a diacetyl rest necessary? From what I read, the d-rest should be done at temps between 65-68, but I am already there. FG is expected to be at 1.012 - this reading is from an iSpindel so its not exact, but the attenuation % should be somewhat acccurate.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)