milldoggy

Well-Known Member

I have a 4 tap remote bar with 25 ft 1/4" id lines. I have been using a corny full of glycol in a mini fridge. It has worked OK, but the temps range between 47-49. Won't go any colder.

Had a dehumidifier that was undersized for my basement. Finally decided to convert it.

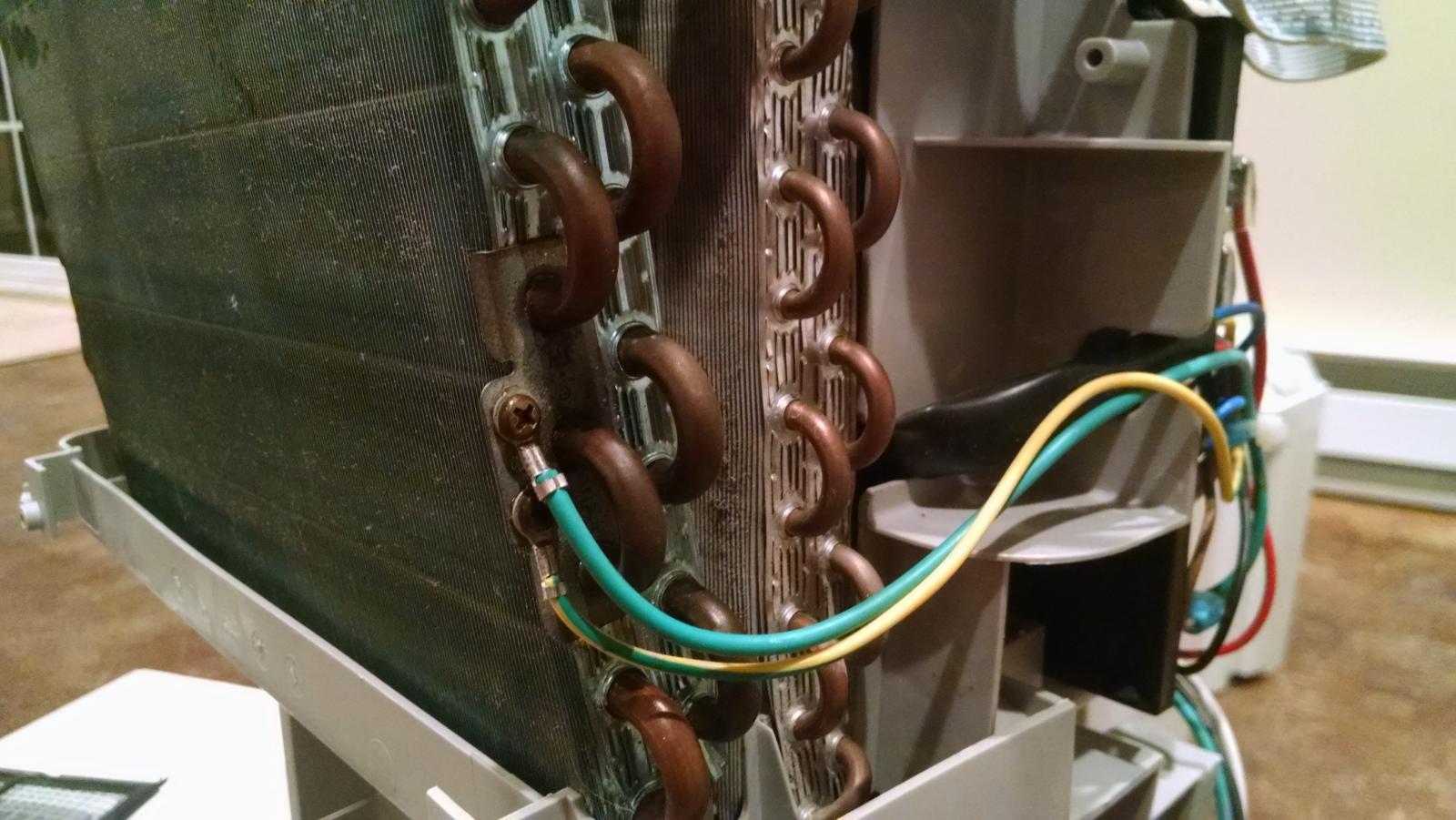

Here it is disassembled and bent into a cooler. Was pretty easy. Had to drill out of the screws holding the evaporator to the radiator.

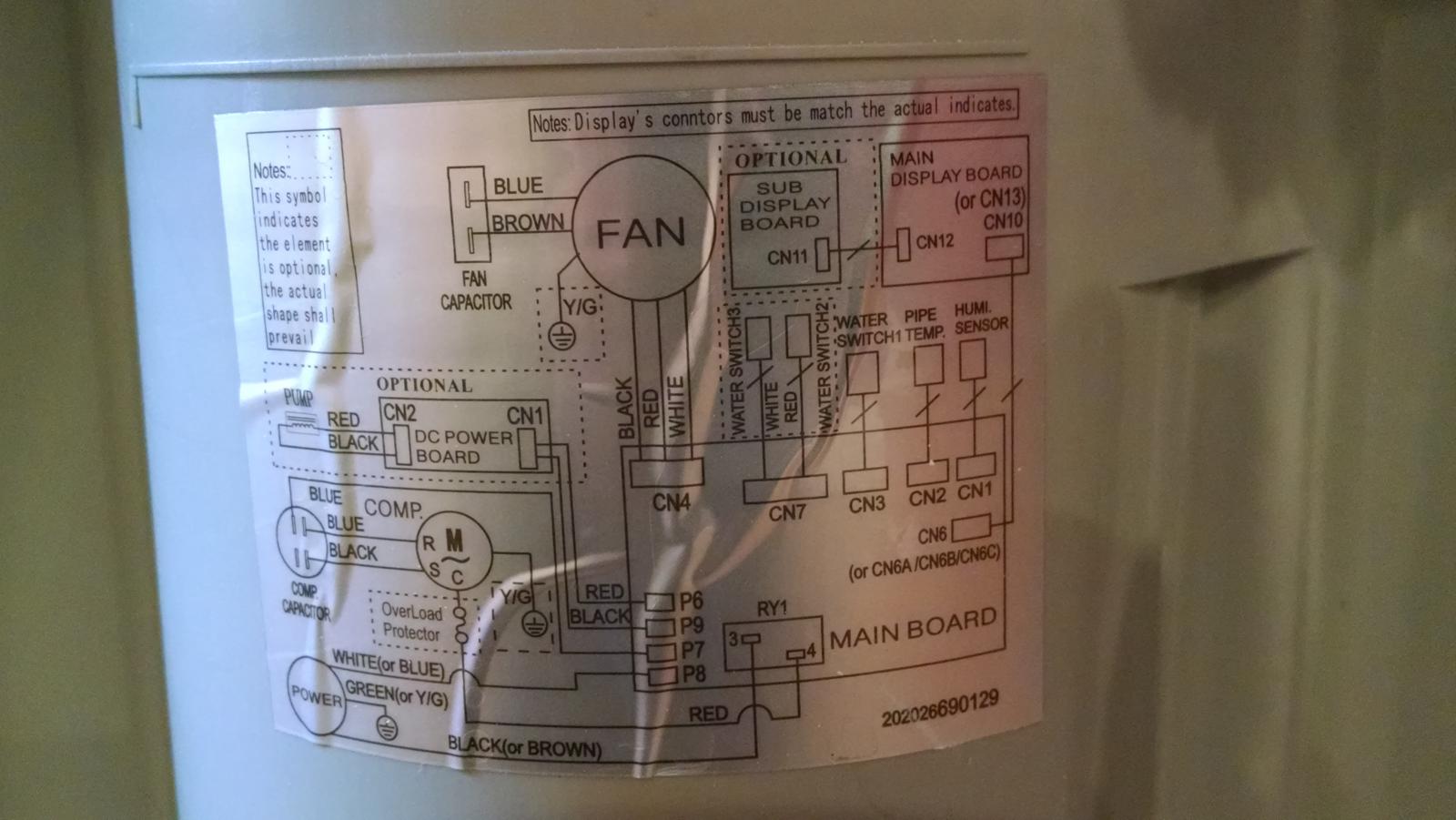

I cut out the humistat and wired in a stc1000 I had laying around. Wiring diagram made this easy.

Using a 28 qt Coleman cooler. Notched at the corner. Ordered 3 gallons of glycol from dudadeisel today.

More pics to come.

View attachment 1439861296112.jpg

View attachment 1439861316117.jpg

Had a dehumidifier that was undersized for my basement. Finally decided to convert it.

Here it is disassembled and bent into a cooler. Was pretty easy. Had to drill out of the screws holding the evaporator to the radiator.

I cut out the humistat and wired in a stc1000 I had laying around. Wiring diagram made this easy.

Using a 28 qt Coleman cooler. Notched at the corner. Ordered 3 gallons of glycol from dudadeisel today.

More pics to come.

View attachment 1439861296112.jpg

View attachment 1439861316117.jpg