Apmarand

Well-Known Member

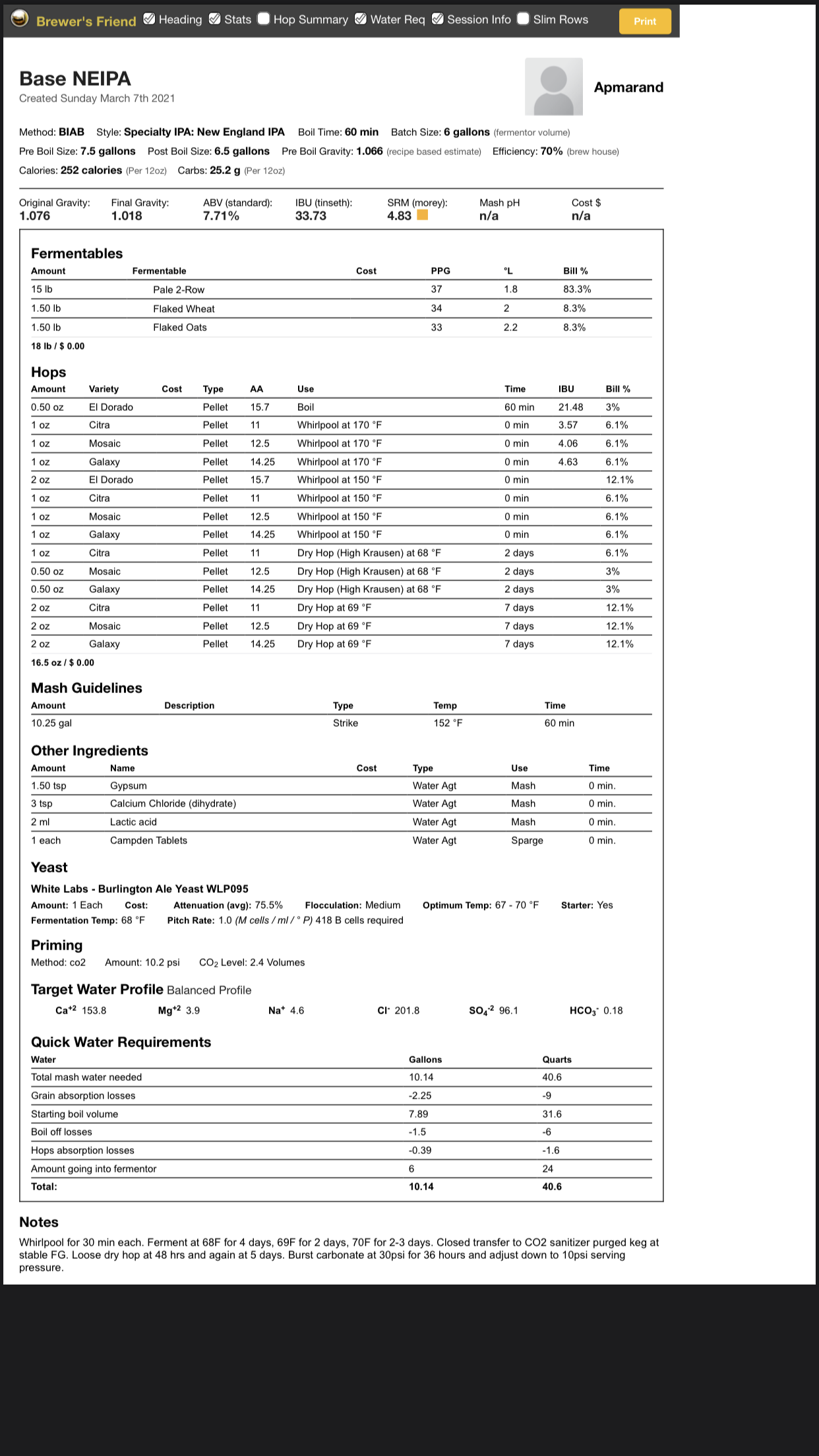

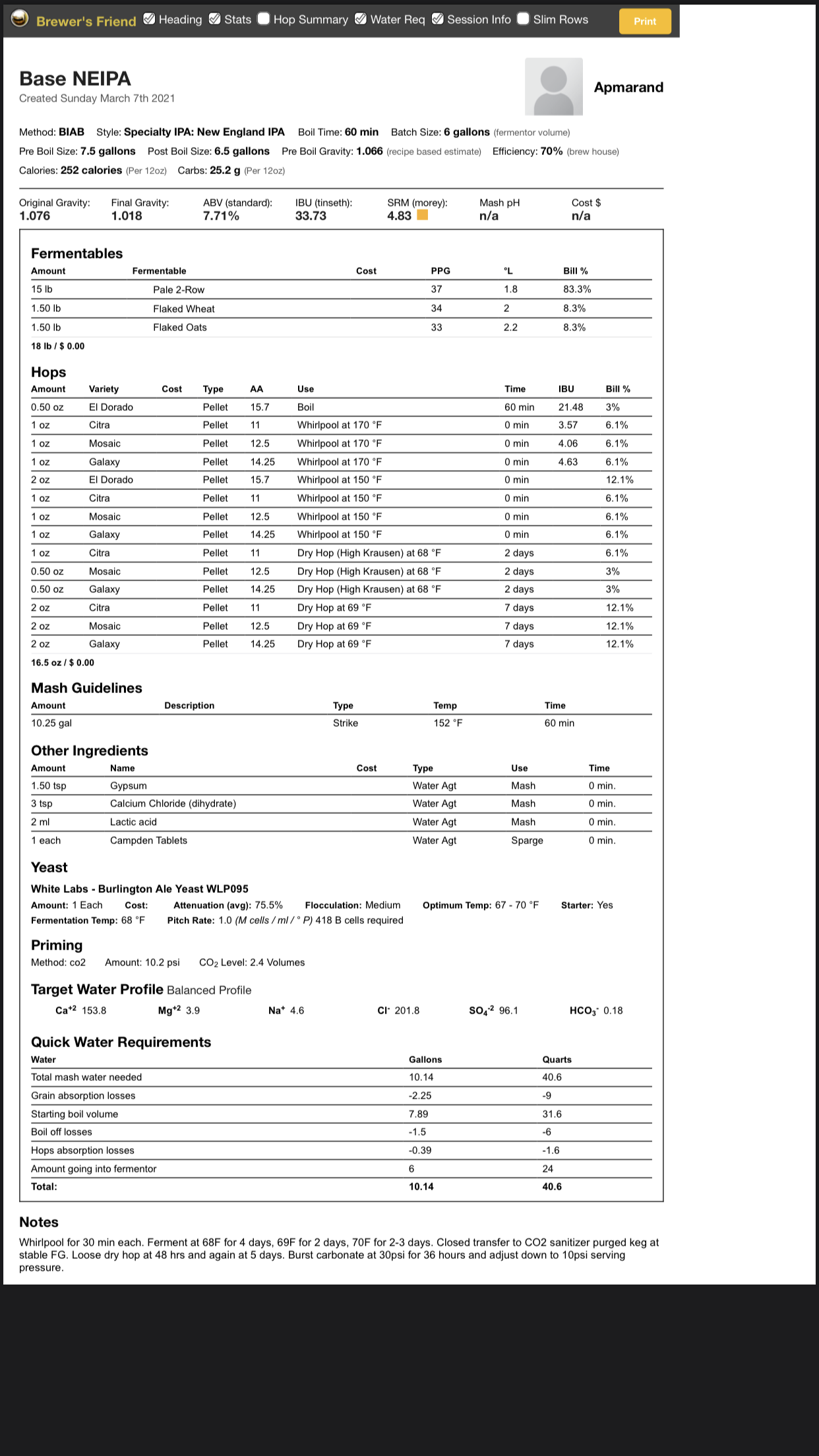

Hi all. I’ve been lurking here for a while and am planning my first BIAB for a NEIPA. I am hoping for some feedback on a recipe (attached). My plan is to add a small bittering charge at 0 min boil and a whopping 15.5 oz after that. I want to make sure I’m not being wasteful with the hop additions, particularly at whirlpool. From what I’ve read, the major dry hop addition (double dry hopped) should come at the tail end of fermentation to avoid too much aromatic loss from CO2. Water chemistry was estimated from my local water report with the help of brewers friend. I am a little unsure of the grain bill as well. Thoughts, suggestions, and criticisms are welcome. Cheers!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)