Quaker said:Can't exactly run down to the LHBS and fetch some flaked corn here. So it's a matter of improvising.

Stock up for the "end" of the world...again.

Quaker said:Can't exactly run down to the LHBS and fetch some flaked corn here. So it's a matter of improvising.

mine was 2 cans of creamed corn in the mash...it worked good..Can't exactly run down to the LHBS and fetch some flaked corn here. So it's a matter of improvising.

Cream Ale Recipe

This is a very simple, inexpensive cream ale recipe that will get every BMC drinker in the room enjoying homebrew. So named because of the three different crops that go into the grist (Barley, Corn and Rice).

I brewed up 10 gallons of this and after kegging, bottled up a case to take to a family event (Mothers Day). Even my 78-yr old FIL, who is strict Miller Lite drinker, ended up having two pints. The chics dug it and we ran out well before the end of the evening.

The grain bill is cheap and in this case, you can use Minute Rice instead of flaked rice. No step mashing required. Simply combine the ingredients and follow a simple single infusion mash at around 152 degrees. I also mashed this for 90 minutes to get a highly attenuated beer. FG was 1.005...leaving a very dry, crisp beer with no noticeable graininess.

While this doesn't adhere to the strict beer laws, and I don't consider this one of my "craft" efforts, it is without a doubt the beer that I get the most "you really made this beer?" comments.

So if you've got some hard core "If it ain't Budweiser it ain't beer " drinking friends give this a try.

This beer clears up quickest of any of my recipes.

View attachment 5581

Batch Size: 11.50 gal

Boil Size: 14.26 gal

Estimated OG: 1.040 SG

Estimated Color: 2.9 SRM

Estimated IBU: 14.3 IBU

Brewhouse Efficiency: 75.0 %

Boil Time: 90 Minutes

Ingredients:

------------

12.00 lb Pale Malt (2 Row) US (2.0 SRM)

4.00 lb Corn, Flaked (1.3 SRM)

1.00 lb Minute Rice (1.0 SRM)

1.00 oz Williamette [5.20%] (60 min)

1.00 oz Crystal [3.50%] (60 min)

Brewed this two months ago did 12 gallons I kegged five normal, and five with cranberry blue berry haven't tasted the regular yet. The cran/blue turned out surprisingly well for being a last minute concoction.

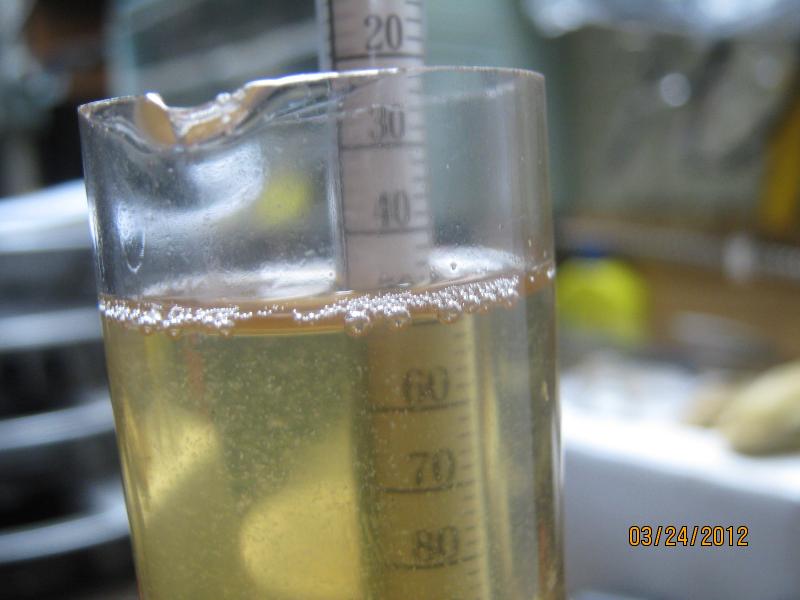

View attachment 54525

Quaker said:After 11 days in primary, the yeast finally dropped out and it cleared up. However, day after day it's had a very strong yeast aroma. I decided to rack to secondary, which I normally forego. I sampled a glass, and yeast is the wrong label. The taste is all corn. Had a very healthy fermentation. I doubt it's DMS. I think it's obviously from the cracked corn. We'll see what a few weeks more will do for it.

G_Brew said:Something went wrong for me... I brewed up a batch of this yesterday right after kegging previous beer... pumped it onto prior yeast... EVERYTHING went perfect... efficiency was through the roof and got 1.052 OG..... THEN - 16 hours later, NO activity... no bubbles, nothing... i'm wondering if my minute rice had some sort of preservatives???? prior sluries usually bubble in a few hours... i'll let it sit longer but i'm very concerned about this batch...

Give it some more time.

G_Brew said:I definately will... anxious to check it out when i get back from work... but in all honesty even if it still starts going, I still feel like something isn't right... should be going by now...

G_Brew said:Well... what can i say....... got home and the thing was fermenting... took almost 20 hours though... everytime i've reused yeast cake it's usualy going within 4-5 hours.... should turn out good! thanks everyone for the tips!

Wonder what the difference was this time? How many times did you reuse this cake?

it's actually the 3rd batch with this yeast.. I'll usually go up to 3 max... but i've never had a problem doing this... and i've heard of people doing up to 5-6 batches on the same yeast... only thing i can think of that is different is the last batch sat on it for over 4 weeks instead of my usual 2 to 3 weeks...

also i cooled the wort to 70 but slowly cooled it down to 60-62 in the following few hours for a slower cleaner fermentation... might have slowed down the start time?

still usually with the billions of hungry yeast cells in a yeast cake desperate for fresh wort there's no stopping em... oh well...

Sorry I didn't want to read through 126 pages. In this recipe do the rice and corn count as the equivalent of a pound of grain for the mash, e.g 8.5lbs total for a 5 gallon batch? Also, what is a good lb/qt ratio for this beer? Thanks in advance!

D_Nyholm said:Made this as well as the Centennial Blonde and Yoopers Fizzy yellow beer and this one was the best tasting of the 3 in my opinion. The only problem is the color of the beer, mine came in very very light, just slightly yellow. Don't know if it is somehing I did or if it is just that light? If so, what would you reccommend increasing or changing to get a little more color? I would say mine is lighter in color than a bud light.

I just went back to the first page and mine is just a little lighter than the pic posted. Wonder what I did wrong?